41

5. INSTALLING AND PIPING THE DSP [Piping the DSP Air Compressor]

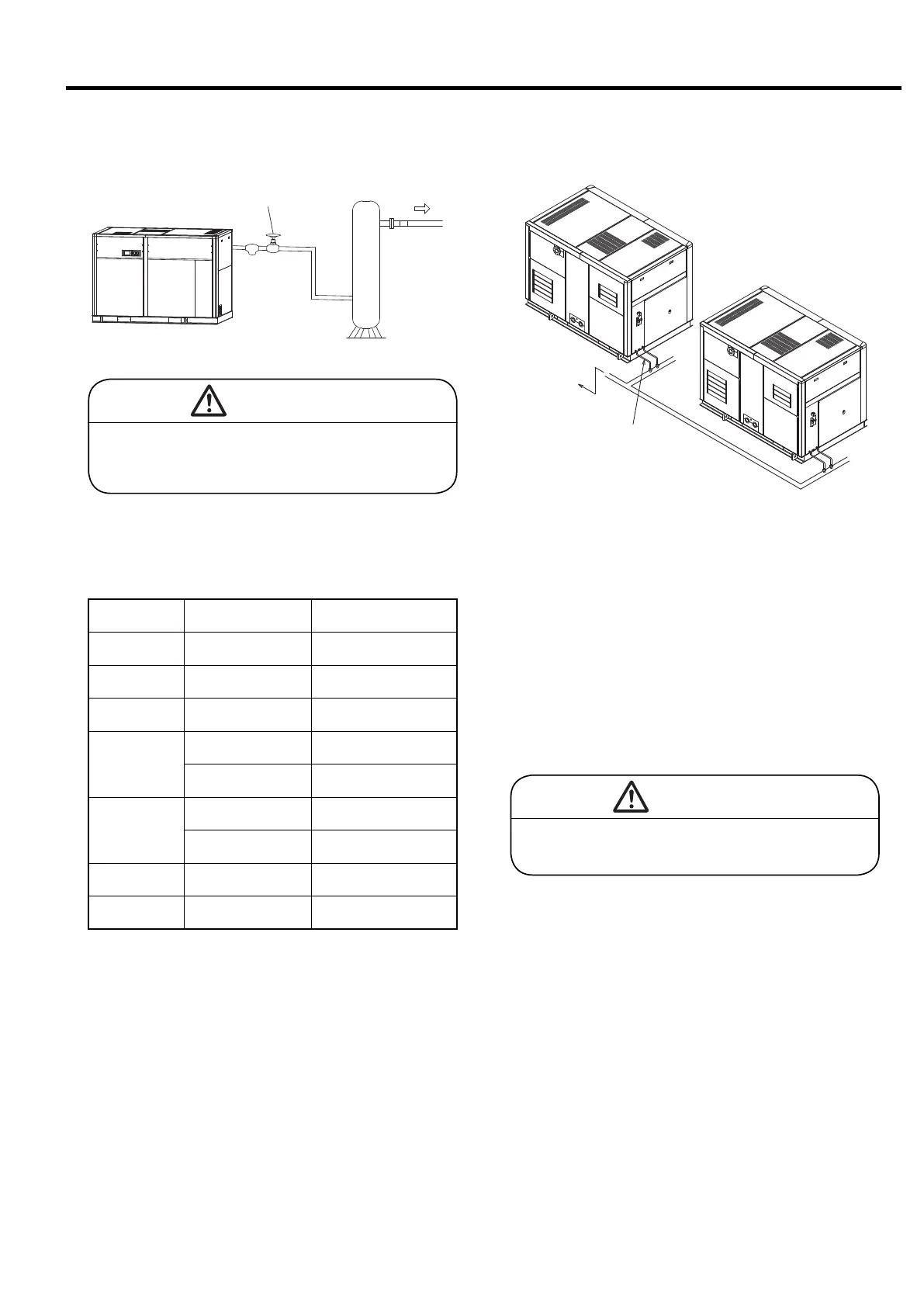

① As the DSP employs a 0%- or 100%-capacity, 2-step

capacity control system, install an air receiver tank on

the plan airline pipe. Its capacity is as indicated in the

following table.

5.4.5 Air Receiver Tank

Discharge

Air

Stop Valve

Air Receiver Tank

Model

Dis.Pressure (MPa)

[psi]

Minimum Capacity of Air

Receiver Tank (m

3

) [US gallon]

DSP-132WN

0.75/0.86/1.0

[110/125/145]

4.0 [1057]

DSP-145WN

0.75/0.86/1.0

[110/125/145]

4.0 [1057]

DSP-160WN

0.75/0.86/1.0

[110/125/145]

4.0 [1057]

DSP-200WN

0.75

[110]

4.5 [1190]

0.86/1.0

[125/145]

4.0 [1057]

DSP-240WN

0.75

[110]

5.0 [1320]

0.86/1.0

[125/145]

4.5 [1190]

DSP-160VWN

0.75/0.86/1.0

[110/125/145]

4.5 [1190]

DSP-240VWN

0.75/0.86/1.0

[110/125/145]

5.0 [1320]

If you fail to install an air receiver tank, the

DSP may load and unload frequently; its

mechanical service life may be shortened.

CAUTION

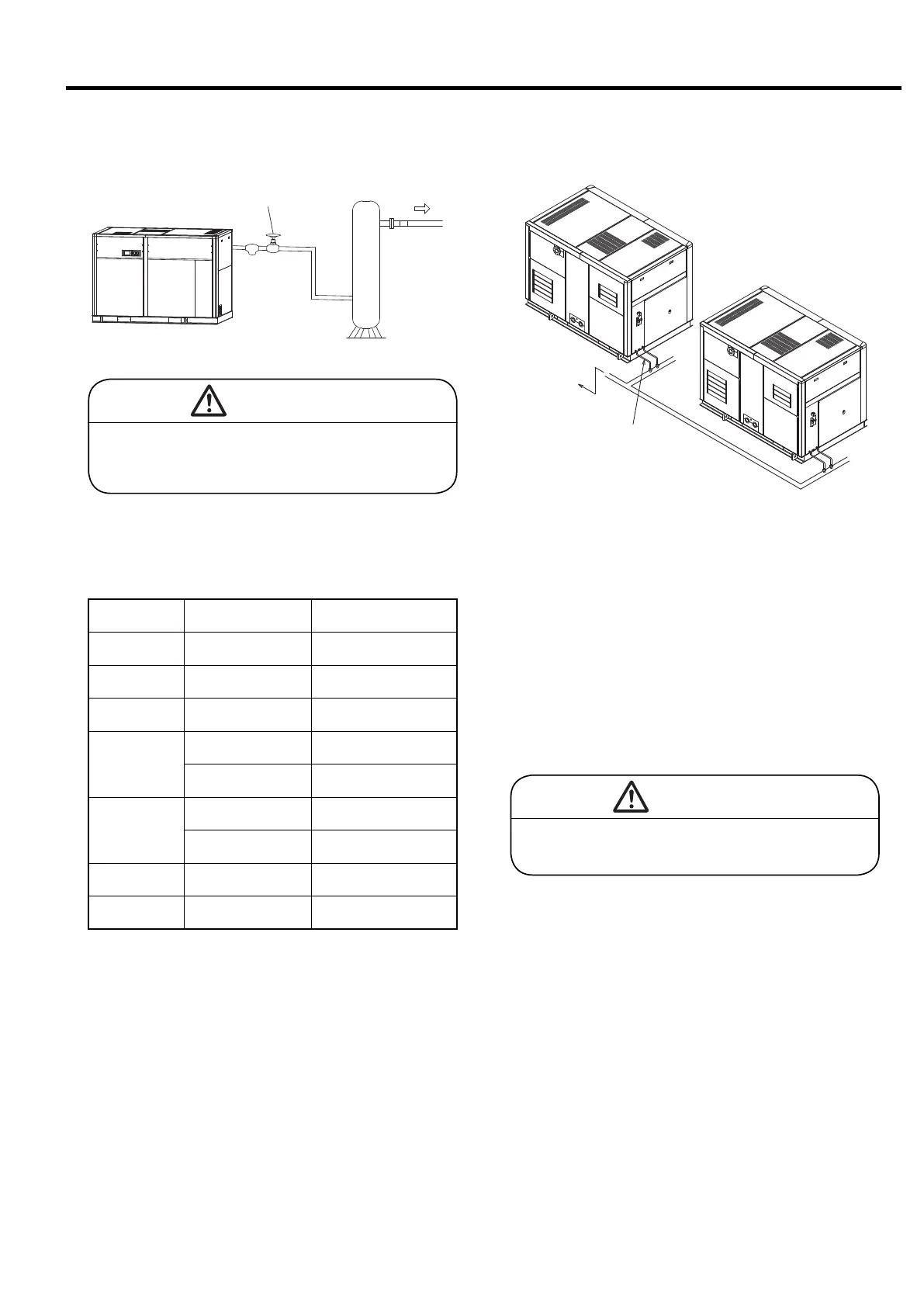

① Leave open the end of any condensate drain pipe.

② Do not merge the DSP’s condensate drain lines (for

the aftercooler, for intercooler, for the control line fil-

ter) into one. Also, do not merge any condensate drain

pipe into an external condensate drain pipe (for exam-

ple, one for other DSPs or one for an air receiver

tank). Otherwise, a pressure difference may be gener-

ated; as a result, the DSP cannot drain the condensate

or can drain it only abnormally or you cannot visually

check whether the condensate is regularly drained.

5.4.6 Condensate Drain Piping

Drain Pit

Drain Pipe

CAUTION

Un-drained condensate can backflow to the

DSP air compressor and cause it to fail.

② Do not install a check valve between the DSP and the

air receiver tank. Otherwise, the DSP may hunt, that

is, load and unload very frequently; the capacity con-

trol system may not work normally.

③However, in case of AUTO operation specification,

quantity control specification and alternate operation

specification, install air chambers of 4.5 m

3

(1190 US

gallon) or more for 132kW to 160kW and 5.0 m

3

(1320

US gallon) or more for 200kW to 240kW so as to max-

imize the energy saving effect.

④When selecting energy saving operation, install air

chambers of 4.5 m

3

(1190 US gallon) or more for

132kW to 160kW and 5.0 m

3

(1320 US gallon) or more

for 200kW to 240kW so as to maximize the energy

saving effect in all the areas of load factors .

Loading...

Loading...