45

6. STARTUP OPERATION [Air Compressor]

②

④

③

RUNNING CONTROL

運転管理

RUNNING MODE

ALARM

警 報

運転状況

故 障

LOAD

SHUTDOWN

REMOTE

負 荷

遠 方

電 源

POWER

起動待ち

AUTO START

停 止

STOP

運 転

START

1

2

記 憶

遠 方

REMOTE

表示切替/

ワイドモード

STR

機 能

FUNC

リセット

RESET

SELECT/WIDE

UNLOAD STOP

①

DIS.PRESS:000psi

NTSTG.P:000psi

OILPRESS:000psi

CLTPRESS:***psi

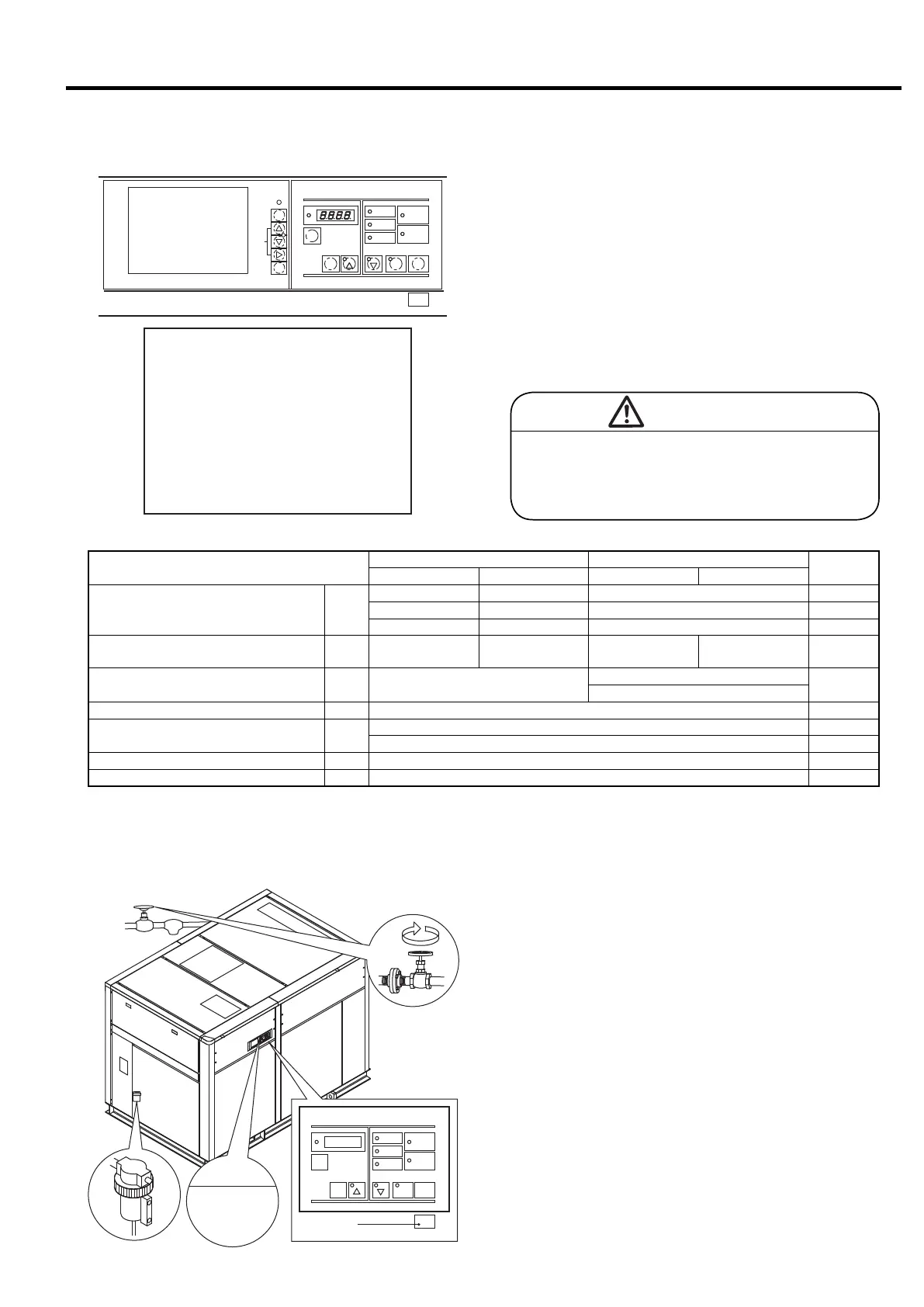

① Check the LCD for operating pressures and tempera-

tures, and verify that:

– Discharge air pressure, interstage air pressure, oil

pressure, discharge air temperature, 2nd-stage suc-

tion air temperature, oil temperature stay within a

normal range; see the table below

② Make sure air containing drain from the inter cooler

drain discharge port and after cooler drain discharge

port is intermittently discharged.

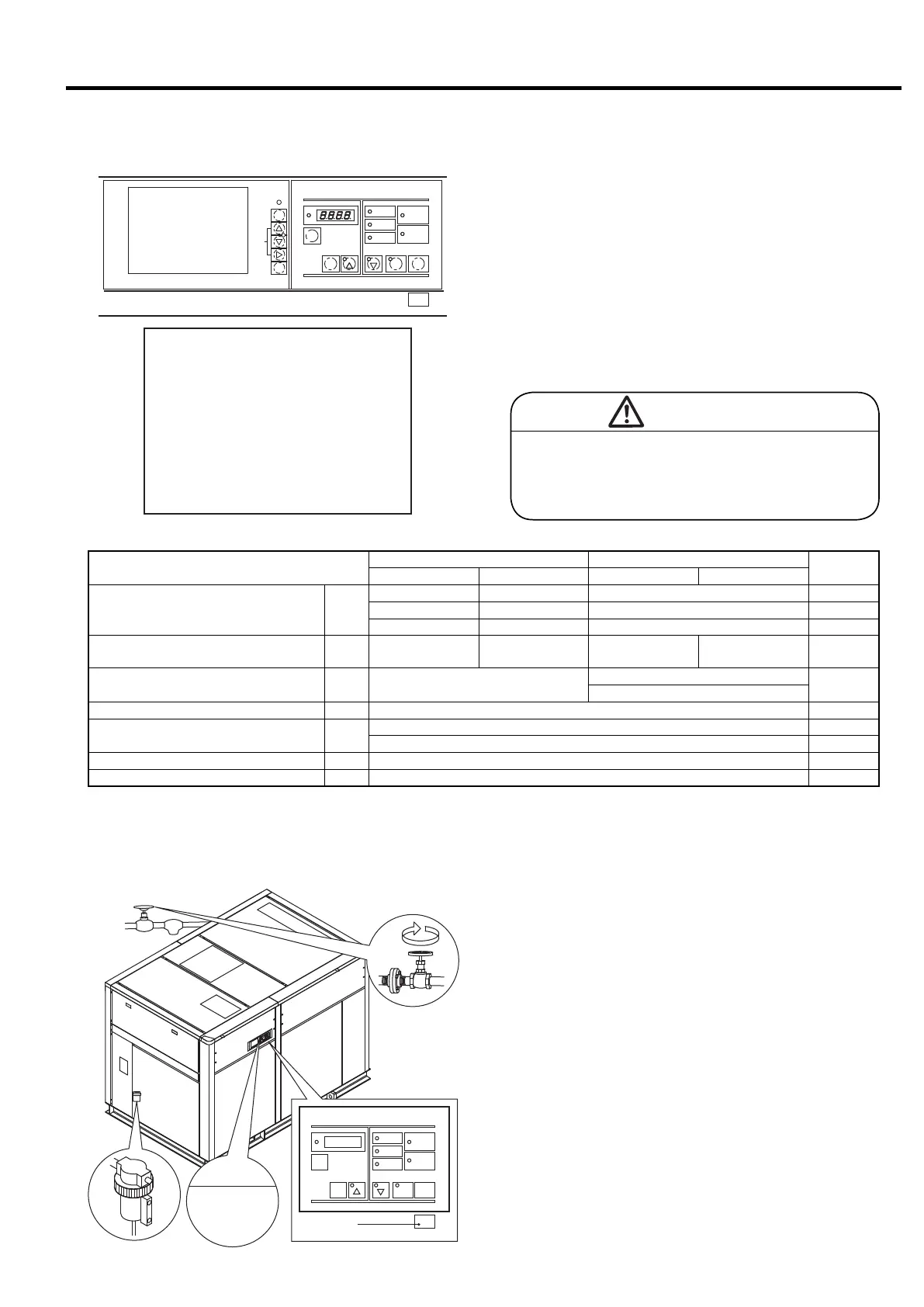

6.1.3 During Operating the DSP Air Compressor

①Press the UNLOAD STOP button. The compressor

then unloads for 5 minutes and then stops running.

(In the case of an emergency, press the STOP button.)

– STOP lamp on the add-on reactor starter panel glows for

reactor model.

② Check the LCD for pressures, and verify that:

– Oil pressure, interstage air pressure, 0 MPa (0 psi) (or 0.01

MPa (1 psi) depending on your operating conditions)

.

③ Check the condensate drain discharge from the con-

trol line filter by checking the sight glass on the con-

trol line filter.

④ Close the discharge stop valve.

⑤ Drain the cooling water.

Open the valve for draining water in the cooling water

piping and drain the cooling water.

To avoid damaging the casing and cooler, be careful

not to allow freezing during the winter.

6.1.4 Stopping the DSP Air Compressor

㻞㻜㻜㻥䠋㻜㻠䠋㻝㻟 㻝㻥䠖㻜㻞

㻼㻾㻱㻿㻿㼁㻾㻱

㻵 㻺㼀㻿 㼀㻳䠊㻼 䠖 㻜䠊㻞 㻜 㼜 㼟 㼕

㻻 㻵 㻸 㻌 㻼㻾㻱㻿䠖 㻜䠊㻝 㻜 㼜 㼟 㼕

㻯㻸㼀䠊㻼㻾㻱㻿 䠖 㻖䠊㻖 㻖 㼜 㼟 㼕

㼀㻱㻹㻼㻱㻾㻭㼀㼁㻾㻱

㻰㻵㻿䠊㼀㻱㻹㻼㻝䠖 㻝㻢㻜䉣

㻰㻵㻿䠊㼀㻱㻹㻼㻞䠖 㻝㻣㻜䉣

㻻 㻵 㻸 㻌 㼀㻱㻹㻼 䠖 㻡 㻤 䉣

㻯㻸㼀䠊㼀㻱㻹㻼䠖 㻖㻖㻖䉣

㻞㻺㻰 㻌 㻿㼁㻯㼀䠊㼀䠊䠖 㻠 㻞䉣

㻹㻭 㻵 㻺㼀 㻱㻺㻭㻺㻯㻱

㻴㻾䠊㼀㻻㻌㻹㻭㻵㻺㼀䠖 㻜㻜㻜㻜䡄

㻺㻱㼄㼀㻌 㻹㻭 㻵㻺㼀䠖 㻖㻖㻖㻖

モニタ

メニュー

リセット

遠方

機能

電源

運転 停止

運転状況

故障

運転管理

負荷

遠方

起動待ち

設定

自動

UP/

DOWN

警報

記憶

表示切替/

ワ イド モ ード

+/−

AUTO

MONITOR

MENU

SET

SELECT/WIDE

2

RUNNINGCONTROL

STARTREMOTE

1

FUNC

[× 10h]

ALARM

STR

REMOTE

RUNNINGMODE

AUTOSTART

POWER

LOAD

RESET

SHUTDOWN

STOP

MONITOR

UNLOAD STOP

Proper Pressure/Temperature Indications on LCD

LCD Indication

Fixed Speed Variable Speed Drive Control

Rated

Pressure

Loading Unloading Loading Purging

Discharge Air Pressure (DIS. PRESS)

MPa

(psi)

0.75 (110) or less

0.65 (94) to 0.75 (110)

0.77 (112) or less 110

0.93 (125) or less

0.76 (111) to 0.86 (125)

0.88 (128) or less 125

1.0 (145) or less

0.9 (130) to 1.0 (145)

1.02 (148) or less 145

Interstage Air Pressure (INTSTG. P)

MPa

(psi)

0.17 (24) to 0.27 (39)

-0.08 (-12) to 0 (0)

0.17 to 0.30 (24 to 43)

0.02 to 0.10 (3 to 15)

110/125/145

Oil Pressure (OIL PRESS)

MPa

(psi)

0.12 to 0.18 (17 to 26) NOTE 1

*0.08 to 0.18 (12 to 26) (Freg. 45Hz or higher)

110/125/145

0.04 to 0.16 (6 to 23) (Freg. less than 45Hz)

1st-Stage Discharge Air Temperature (DIS. TEMP1)

℃ (°F)

185 (365) or less

NOTE 2

110/125/145

2nd-Stage Discharge Air Temperature

(DIS. TEMP2)

℃ (°F)

225 (437) or less

NOTE 2

110/125

240 (464) or less 145

Oil Temperature (OIL TEMP)

℃ (°F)

63 (145) or less

110/125/145

2nd-Stage Suction Air Temperature (2ND SUCT. TEMP)

℃ (°F)

63 (145) or less

110/125/145

NOTES: 1. The oil pressure may exceed 0.18 MPa temporarily when starting the DSP. this is normal.

2. The discharge temperature varies from model to model. Refer the caution decal on the front panel of the unit for details.

During inspection of the operation of the safety

relief valve, use the appropriate facial protec-

tion. High pressure air containing dust particles

can cause severe injury.

WARNING

Loading...

Loading...