Do you have a question about the Hofmann Snap-on Y2k and is the answer not in the manual?

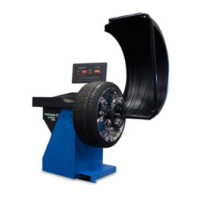

Details the different configurations of the Y2k balancing platform.

Describes the unbalance transducers and temperature sensor.

Step-by-step guide for installing and pre-stressing transducers.

Procedures for checking transducer electrical integrity.

Details the main shaft incremental encoder.

Describes the incremental encoder for the power-clamp system.

Explanation of the manual drive system.

Explanation of the motorized drive system.

Describes brakes used for stopping the main shaft after measurement.

Explains the mechanisms for locking the main shaft.

Details the operation of the power-clamping system.

Procedure for releasing a wheel during a power outage.

Configuration settings for the standard CMOS setup.

Configuration settings for BIOS features.

Configuration settings for chipset features.

Configuration settings for power management.

Configuration of integrated peripherals.

Checks communication, keyboard, memory, model, and pedal switches.

Tests OPTIMA hardware, calibration, and specific functions.

Verifies voltage lines, LED current, transducer signals, and auto stop system.

Checks SAPE arm positions, calibration status, and service intervals.

Checks overall calibration, service intervals, and specific arm calibrations.

Lists and describes kernel error codes starting with 'H'.

Lists and describes error codes starting with 'E'.

Defines the structure and components of kernel error codes.

Lists and describes module IDs associated with error codes.

Defines the frequency, duration, and pause for different beep types.

Explains sequences of beeps indicating initialization or errors.

A comprehensive list of service codes and their functions.

Instructions for entering C codes on CRT models.

Instructions for entering C codes on GS models.

Instructions for entering C codes on HWT models.

Instructions for entering C codes on JBEG models.

Instructions for entering C codes on Truck models.

How to save operational settings, calibration data, and reset the system.

General initialization procedures and common features.

Specific initialization steps for B9000, B9450, and B9460 models.

Details the functionality of the SAPE arm for data entry and weight application.

Explains general wheel spin behavior and error codes.

Details spin initiation and stopping for different models.

Specific auto-orientation features for B9460.

Allows toggling between high and low resolution display of unbalance.

Procedure for calibrating the balancer by the user.

Lists and explains available service codes.

Resets the balancer to factory default settings.

Adjusts the volume level for audible signals.

Configures the auto-orientation or sticky-on-top mode for B9460.

| Brand | Hofmann |

|---|---|

| Model | Snap-on Y2k |

| Category | Wheel Balancers |

| Language | English |