บริษัท เอดีดี เฟอร์เนส จํากัด

ADD FURNACE CO.,LTD.

44 ซอยบรมราชชนนี 70 ถนนบรมราชชนนี แขวงศาลาธรรมสพน์ เขตทวีวัฒนา กรุงเทพฯ 10170

โทร: 02-888-3472 โทร: ออกแบบ:08-08-170-170 แฟกซ์: 02-888-3258

https://www.add-furnace.com E-mail: sales@add-furnace.com

INSTALLATION AND OPERATION

PLANNING THE INSTALLATION

Proper flame detector application is the back of a safe and

reliable flame safeguard installation. Refer to the burner

manufacturer’s instructions as well to those included here.

Follow all instructions carefully.

CAUTION

1. Do not connect these detectors to non-

Honeywell manufactured controls (primaries,

programmers, multiburner systems, and

burner management systems). Unsafe

conditions could result.

2. Disconnect power supply before beginning

installation to prevent electrical chock and

equipment damage. More than one

disconnects may be involved.

3. All wiring must be NEC Class 1 (line volt-

age).

4. Voltage and frequency of the power supply-

connected to this detector must agree with

the values marked on the detector.

5. Sight the detector so it does not respond to

ignition spark.

6. On multiburner installations, each detector

must respond only to the flame of the burner

it is supervising.

IMPORTANT

Do not connect more than two C7061A/F flame

detectors in parallel.

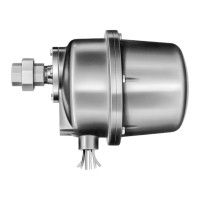

Basic Requirements

The combustion flames of most carbon-based fuels emit

sufficient ultraviolet radiation to enable the C7061A/F Solid

State (Purple Peeper) ultraviolet flame detector to prove the

presence of a flame in a combustion chamber. The

detector mounted outside the combustion chamber. Its

mounting flange or union is threaded to one end of a sight pipe

inserted through the wall of the combustion chamber. The

ultraviolet sensing tube in the flame detector sights the

flame through the pipe.

When a flame is present, the UV tube in the C7061A/F

senses the ultraviolet radiation emitted. The C7061A/F pro-

duces a signal that is sent to the amplifier in the flame safe-

guard control. The amplified signal pulls in the flame relay in

the control to allow proper operation of the system.

Because it is necessary for the UV sensing tube to actually

see the flame, it is best to locate the detector as close

to flame as physical arrangement, temperature, and other

restrictions permit. These restrictions are described in detail

in the following paragraphs.

Determine the location

Before beginning the actual installation, estimate the best

location for mounting the detector based upon these factors:

1. Temperature

Install the flame detector where the surrounding

temperature will remain within the specified ambient

operating temperature ratings.

For the C7061A/F, to keep the detector temperature within

specification. If the temperature rating is exceeded, the

introduction of cooling air will be necessary.

2. Vibrations

Do not install the detector where it could be subject of

excessive vibration; it shortens the life of the electronic com-

ponents. Vibrations with a magnitude greater than 1g will

require an anti-vibration mount to cushion the detector.

3. Clearance

Make sure there will be enough room to remove the cover of

the detector for servicing.

Radiation sources other than flame

Examples of radiation sources, other than a flame , which

could actuate the detection system:

Ultraviolet sources

•

Radiant surfaces above 1200°C (2200°F).

•

Sparks from ignition transformers and welding arcs.

•

Gas lasers

•

Sun lamps

•

Halogen lamps

•

Germicidal lamps

•

incandescent lamps held close to the sensing tube

•

Filament above 1200°C (2200°F).

Gamma ray and X-ray sources

•

Diffraction analyzers

•

Electron microscopes

•

Radiographic X-ray machines

•

High voltage vacuum switches

•

High voltage condensers

•

Radioisotopes

Except under very unusual circumstances, none of these

sources, except a radiant surface or ignition spark, would

be present in or near the combustion chamber. The

detector may respond to a radiant surface at a temperature

above 1200°C (2200°F) if both of the following conditions are

present the surface represents a significant percentage of

detector’s field of vi w.

If the temperature or a radiant surface causes the flame

relay (in the flame safeguard control) to pull in, re-aim the

sight pipe so the detector views a cooler area, or the

sensitivity of the detector decreases. Ignition sparks is a

rich source of ultraviolet radiation.

Loading...

Loading...