บริษัท เอดีดี เฟอร์เนส จํากัด

ADD FURNACE CO.,LTD.

44 ซอยบรมราชชนนี 70 ถนนบรมราชชนนี แขวงศาลาธรรมสพน์ เขตทวีวัฒนา กรุงเทพฯ 10170

โทร: 02-888-3472 โทร: ออกแบบ:08-08-170-170 แฟกซ์: 02-888-3258

https://www.add-furnace.com E-mail: sales@add-furnace.com

INSTALLATION

CAUTION

1.

Installer must be a trained, experienced flam

safeguard control serviceman.

2.

Disconnect power supply before beginning

installation to prevent electrical shock and

equipment damage.

3.

All wiring must comply with applicable local

electrical codes, ordinances, and regulations.

4.

Voltage and frequency of power supply connected

to this detector must agree with the values

marked on the detector.

6.

On multiburner installation, each detector must

respond only to the flame(s) produced by the

burner it is supervising.

7.

Do not connect more than two detectors in parallel

to a single R7061 or R7861A Dynamic Self-Check

Ultraviolet amplifier.

8.

Perform all required adjustments and check- out

tests after installation is complete.

Install the Sight Pipe

After you have determined the location and sighting angle, select

the sight pipe. A black iron pipe with a diameter of at least 1-1/2 in.

(38.1 mm) is recommended. Do not use stain- less steel or

galvanized pipe because they reflect ultraviolet radiation internally

and complicate aiming the pipe.

Sight pipes with diameters 2 to 3 in. (51 to 76 mm) produce better

results for horizontal rotary burners, which require wide viewing

angles. A wide viewing angle can also be obtained by using a

short sight pipe.

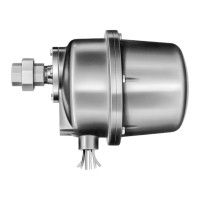

Fig. 5. Typical mounting of C7061A/F

Prepare Hole in Wall of Combustion Chamber

Cut or drill a hole of the proper diameter for the sight pipe in the

wall of the combustion chamber at the selected location.

Flare the hole to leave room for small adjustments of the sighting

angle. The taper of the hole should be about 1 in. for every 3 in.

(25 mm for every 76 mm) of Wall thickness.

Mount Sight Pipe

Thread one end of the pipe to fit the mounting flange, union,

or required coupling. Cut the pipe to the desired length (as short as

practical) and at an angle so it fits flush with the wall of the

combustion chamber. Tack- weld the pipe to the wall in a trial

position. Do not weld the sight pipe permanently in place until

after completing the Adjustments and Checkout.

Install Fittings

In some cases, the sight pipe does not directly fit the C7061A/F

mounting flange or union. Also, it may be desirable or necessary

to ventilate the sight pipe. You may also want to use a swivel

mount or an antivibration mount. Each of these cases may require

additional fitting.

Reducer

For sight pipes of larger diameter than the mounting flange

connector or union, install a reducer as illustrated in Fig. 5. The

reducer will require a close nipple with these external threads: 3/4

or 1 inch. NPT.

Sight Pipe Ventilation

It may be necessary to ventilate the sight pipe to cool the detector

or to clear a viewing path through UV radiation attenuating

material.

For a negative pressure combustion chamber, drilling a few holes

in the section of the sight pipe outside of the combustion chamber

will allow air at atmospheric pressure to flo w through the sight

pipe and into the chamber. A perforated pipe nipple between the

sight pipe and the detector can also be used.

For a positive pressure combustion chamber, connect a supply of

pressurized air from the burner blower to flow through the sight

pipe and into the chamber. The air pressure must be greater than

the chamber pressure.

Swivel Mount (C7061A only)

To facilitate proper flame sighting, use part no. 118367A Swivel

Mount (not supplied). The swivel mount requires a reducer of the

proper size to mount it onto the sight pipe. It also requires a

one-inch close nipple for mounting to a C7061 with a one-inch

connector. (For 118367A Swivel Mount mounting details, refer to

form 60-0361).

Antivibration Mount

The detector withstands normal burner vibration. If the vibration is

excessive, part no. 123539 Antivibration Mount is available. (For

mounting details, see form 60- 0361). If you use this mount, install

it before positioning and sighting the detector.

Mount the Detector

Mount the detector onto the sight pipe, reducer, or other fit ting.

The C7061A/F Self-Checking flame detectors incorporate an

oscillating shutter mechanism and, therefore, require special

consideration for mounting positions other than vertically sighting

downward or upward, as illustrated in Fig. 6. The C7061A/F has

notch and arrow indicators (see Fig. 7 and 9) on the faceplate to

facilitate mounting in positions other than those shown in Fig. 7.

The notch and arrow must be vertically aligned with the notch in the

up position and the arrow pointing downward (see Fig. 7). The

C7061A/F must be mounted with the conduit opening located

approximately 45 degrees below the horizontal

Loading...

Loading...