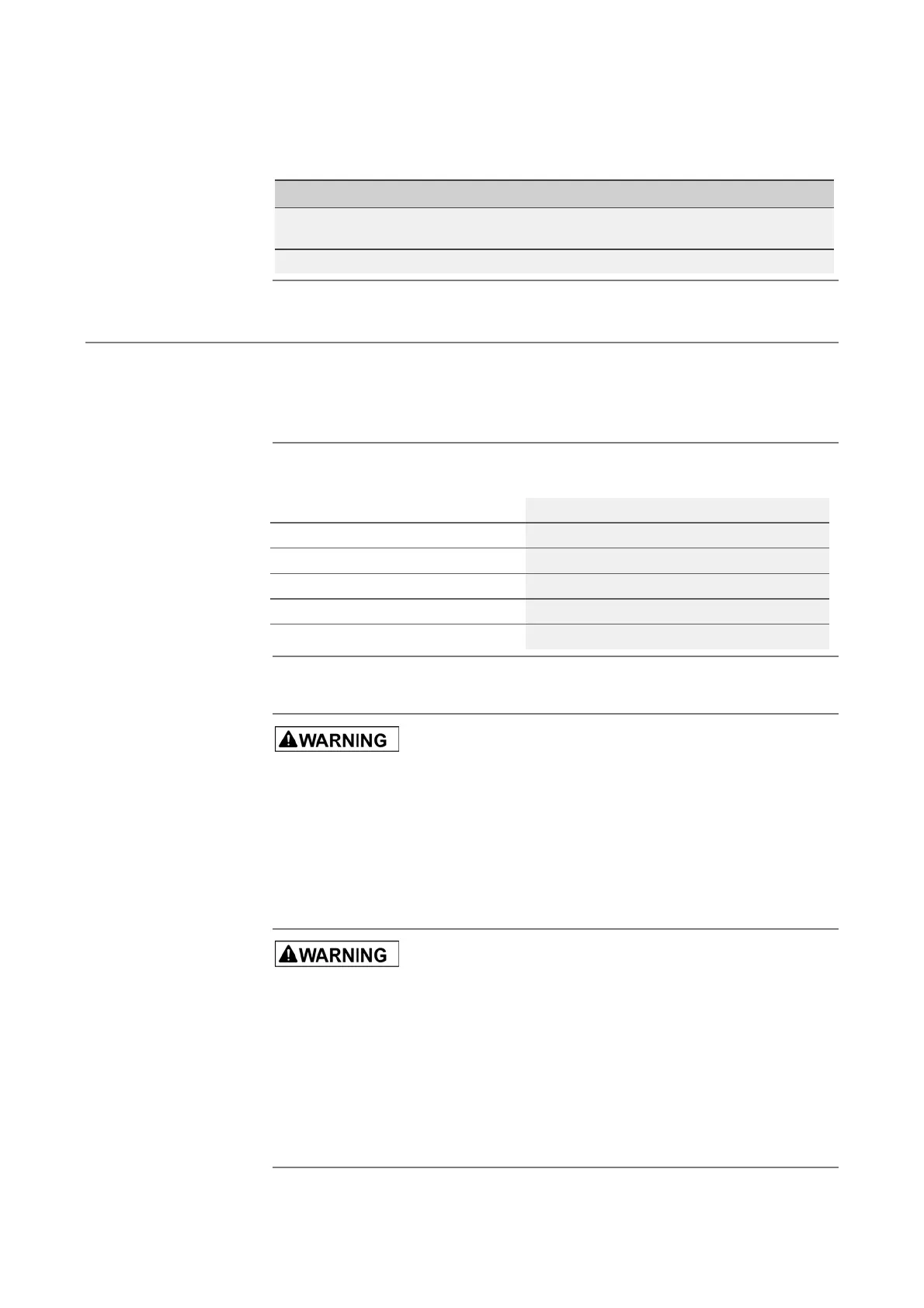

Transport,installationandstart‐up

UsermanualforHONR100gaspressureregulatorwithHONP095NGpilot 36

Conductafinalinspectiontocheckwhetherthefollowingcriteriaaremet:

Allscrewedconnectionsonthedeviceandsupplylinesaresecurelyfastened.

If… then…

atleastonecriterionisnotmet

youshouldcorrecttheerrorbeforeproceeding

withthenexttask.

allcriteriaaremet youmayproceedwiththenexttask.

Proceedasfollows:

Checkingthesystemforleaks(seepage36)

5.4 Checkingthesystemforleaks

Priortodelivery,themanufacturerconductedapressureandleaktestonthegaspressure

regulatorasspecifiedinDINEN334.

Thegaspressureregulatorinstalledinthesystemmustbesubjectedtoaleaktestatthe

setuplocationasfollows:

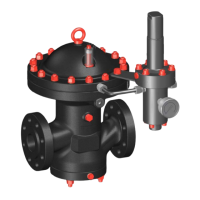

Normativebasis DVGWCodeofPracticeG491

Testmethod Bubbletestmethod

Testmedium Airorinertgas

Scopeofthetest Alldetachablepipejoints

Testequipment Foam‐generatingleakagemedium

Testpressure 1.1timestheoperatingpressure(MOP)

Thedeviceinstalledintothesystemmustundergoaleaktestattheset‐uplocationinac‐

cordancewithapplicableinternationalandnationalstandards.

Riskofseriousinjuryposedbypressurizedcomponentsmovinginanuncontrolledmanner

whenhandledimproperly.

Ifnothandledproperlyorintheeventofadefect,gascanescapefrompressurizedcompo‐

nentsunderhighpressureandcauseseriousinjuriesandevendeath.Beforeyoustartwork‐

ingonthesecomponents:

Closeallconnectionsleadingtothegas‐carryingline.

Establishadepressurizedstatus.Residualamountsofenergymustbedepressurizedas

well.

Riskofinjuryposedbyburstingpartsintheeventthattheyaresubjectedtopressurein

thewrongdirection

Thedevicehasbeendesignedforaspecificdirectionofflow,whichislabeledonthedevice.

Subjectingthedevicetopressureinthewrongdirectionmayresultinseriousinjurycaused

byburstingparts.

Pressurizethesystemonlyontheinletside.

Detailsabouttheoperatingpressurecanbefoundinthetechnicalspecifications(seepage

17).

Finalinspection

Nexttask

Leaktestconductedby

themanufacturer

Leaktestattheset‐up

location(inGermany)

Leaktestattheset‐up

location(inothercoun‐

tries)

Pressurizedparts

Pressurizedparts

Loading...

Loading...