4-7

4.3 Sample and Exhaust Tubing Calculations

The following tables show the flow rate, tubing

length, transport time, and maximum pressure and

vacuum at the inlet and exhaust points. Tubing

lengths vary among gases. See Appendix B for

recommended lengths.

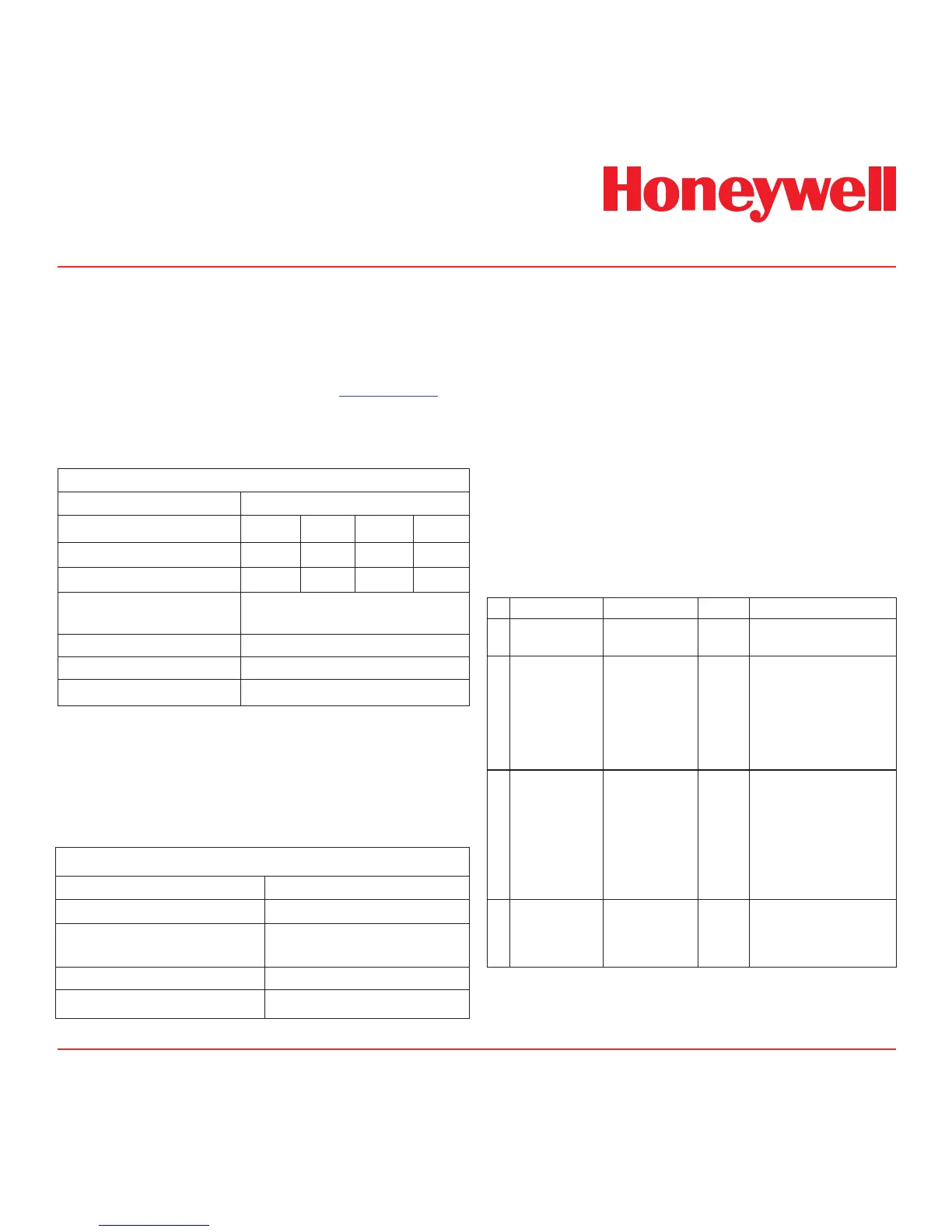

Table 4-1. Inlet sample specications

Inlet Sample Specifications:

Maximum

Tubing Length, m (ft)

30 (100) 20 (66) 10 (33) 0

Transport Time (sec), ID 1/8”

1

28 19 10 1

Transport Time (sec), ID 3/16”

63 43 23 1

Sample Point Vacuum

(Negative pressure)

-25.4 cm H

2

O (-10 in H

2

O) Maximum

Flow rate, cc/min.

500 (Flow is constant)

2

Tubing OD, mm (in)

6.35 (0.25)

Tubing ID, mm (in)

3.18 (0.125)

1

Honeywell Analytics recommends thick-wall tubing (1/8” ID)

for best speed of response. Due to its lower surface area, thick-

wall tubing may require less conditioning than thin-wall tubing.

2

The ow rate is electronically maintained at approximately

500 cc/min and may vary within acceptable tolerances.

Table 4-2. Outlet sample specications

Outlet Sample Specifications:

Maximum

Tubing Length, m (ft)

30 (100)

Back Pressure at Exhaust Point

(Excluding tubing)

20.3 cm H

2

O (8 in H

2

O) Maximum

Tubing OD, mm (in)

6.35 (0.25)

Tubing ID, mm (in)

4.76 (0.188)

Note

Honeywell Analytics recommends the use of

Teon FEP (Fluorinated Ethylene Polymer)

tubing to assure proper sample transport.

The properties of Teon FEP make it the

best choice for transporting sample toxic

gases to instruments when compared with the

properties of other similar tubing materials.

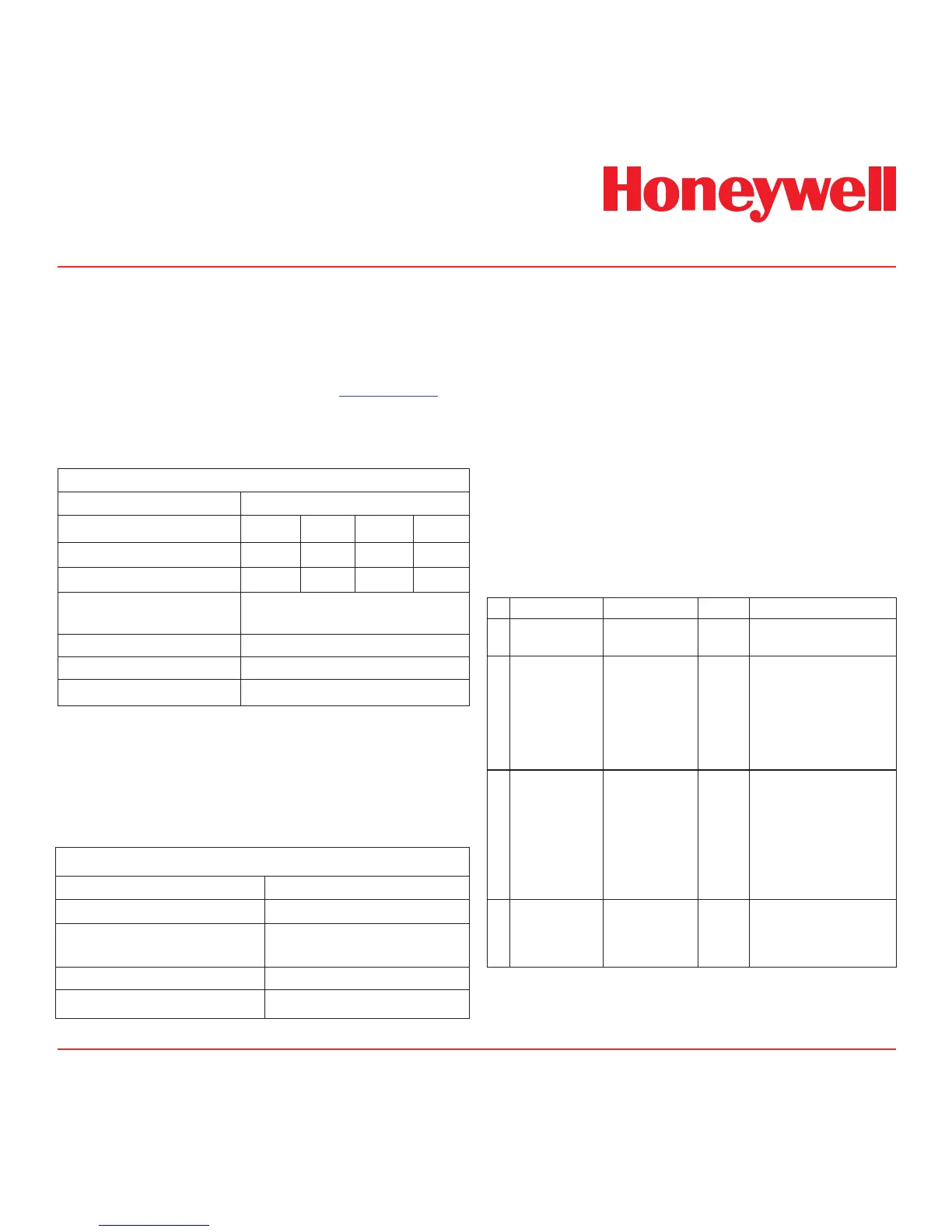

If the pressure/vacuum on the inlet/exhaust lines

does not meet the recommended values in Tables

4-1 and 4-2, the following chart describes potential

fault conditions that may be brought on by the

external influences thus resulting in an F81 Flow

Fault.

External Flow Fluctuation Fault 81 Explanation

1

Low

(0-150 cc/min)

None No Midas

®

will auto-adjust

2

Low

(0-150 cc/min)

Yes

(up to 100 cc/

min flow swings)

Likely

Midas

®

changes the flow

gradually. If external flow

changes are large and rapid,

the final reading will be

different from what Midas

®

expected.

Midas

®

will issue

Fault 81.

3

Medium

(~200-450 cc/

min)

Yes and No Yes

Minimum flow rate for the

pump is ~300 cc/min. With

this external flow, the auto-

adjust cannot work because

the pump cannot produce

a flow at this low level. The

problem is worse if there are

flow fluctuations.

4

High

(> 600 cc/min)

Yes and No Yes

Midas

®

cannot reduce the

external flow. Midas

®

will

issue Fault 81 due to high

flow

Loading...

Loading...