9-3

To maintain sensor accuracy when using the

pyrolyzer, perform a gas calibration every six

months. Do not allow the ambient temperature at

the point of installation to exceed 40°C (104°F).

Operation above this temperature may require

more frequent bump testing or calibration to

confirm working specification. Because of the

higher operating temperatures when using the

pyrolyzer module, Honeywell Analytics strongly

recommends that the ventilated Midas Top

Cover (part number MIDAS-A-039) be used in all

pyrolyzer applications.

NOTE: The Pyrolyzer module is serviceable only

by trained personnel or by Honeywell Analytics’

Service Center. Inappropriate handling can cause

injury and device damage.

Note: Le module pyrolyzer pouvant-être réparé.

Par contre la réparation doit-être effectuée par

un personnel qualifié ou à un centre de service

autorisé d’Honeywell Analytics. Une manutention

inadéquate pourrait causé des blessures ainsi que

des dommages à l’appareil.

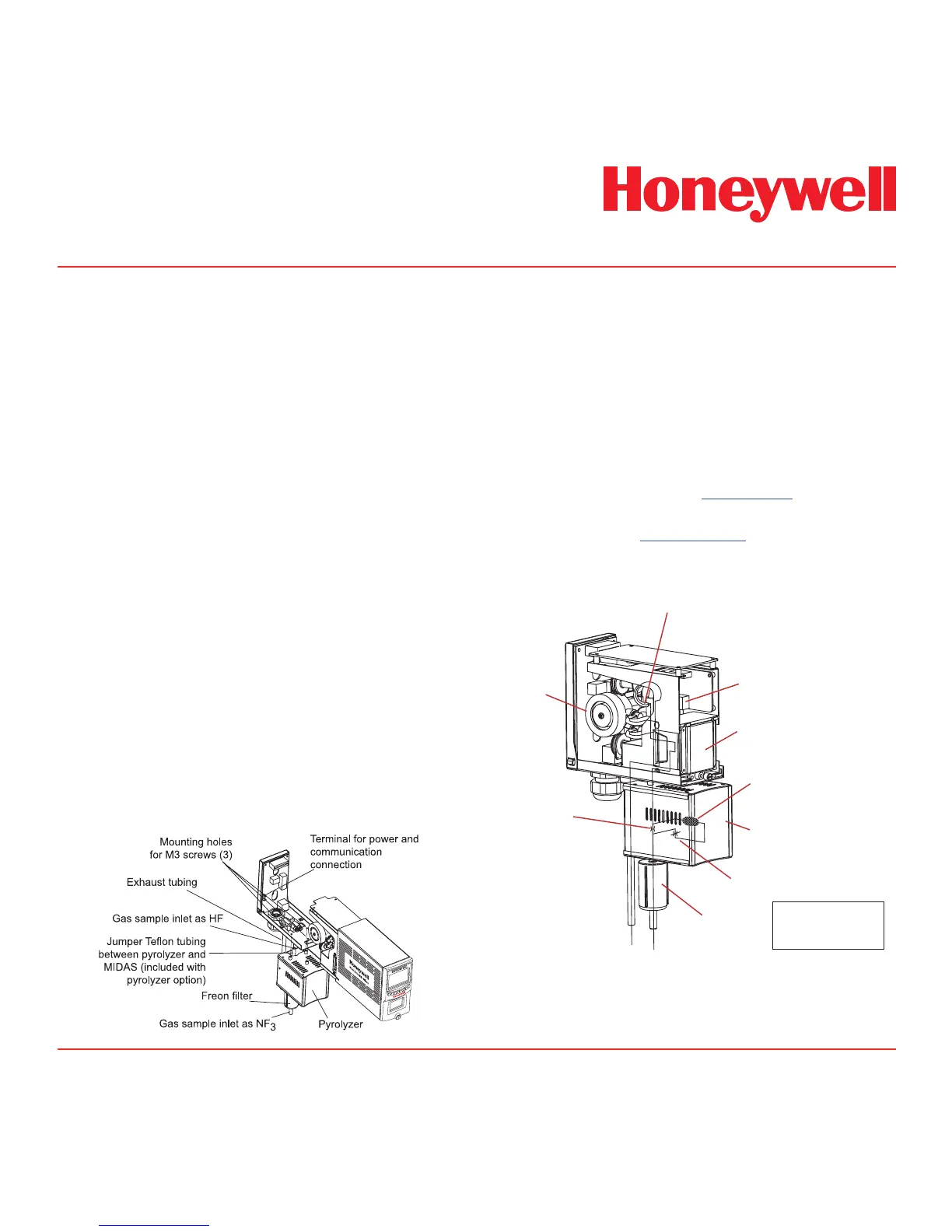

Diagram 9-2 shows the main components of the

pyrolyzer.

Diagram 9-2. Pyrolyzer components.

Diagram 9-2. Pyrolyzer components.

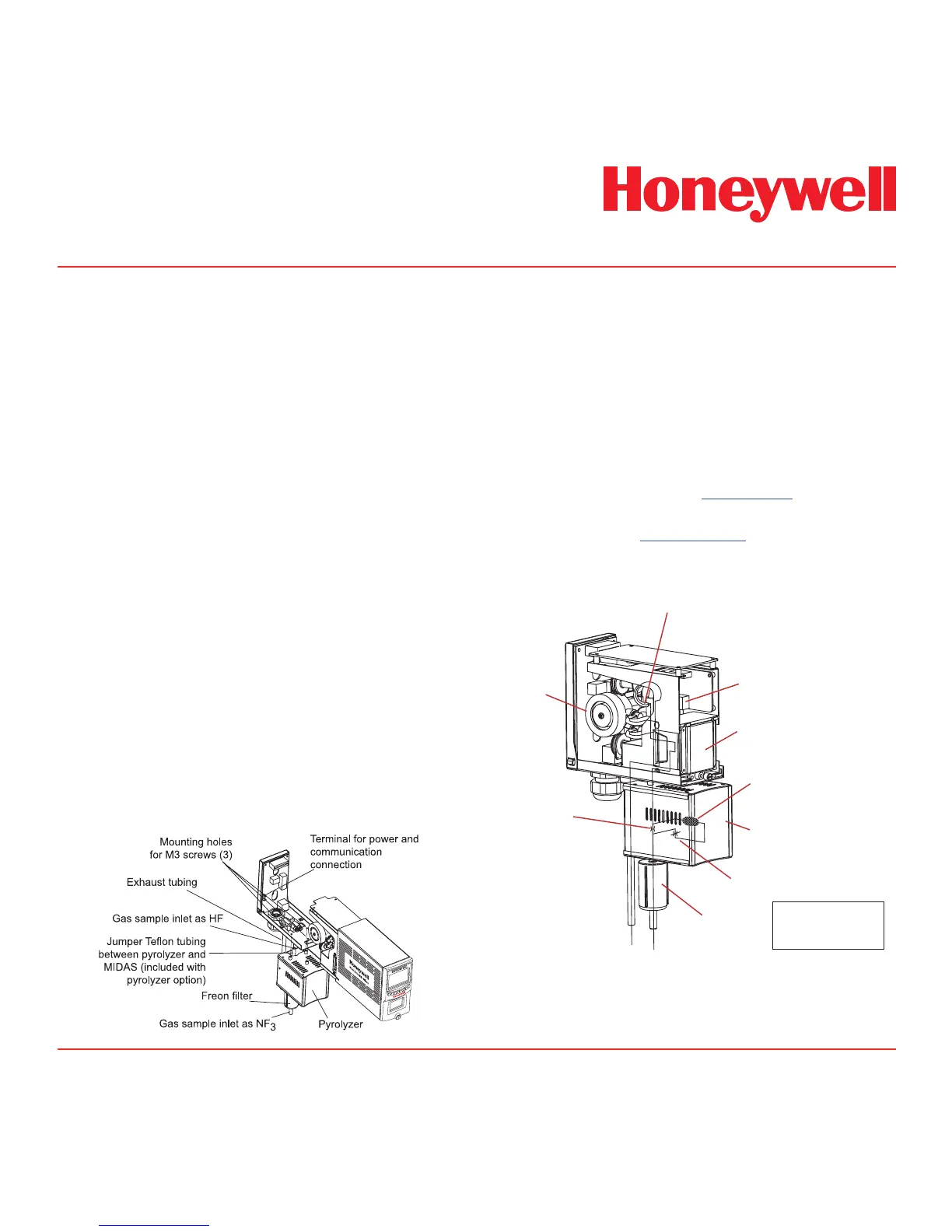

Diagram 9-3 shows in a simple form how a gas

sample is drawn through the pyrolyzer module by

the pump (located at the end of the gas path). It

is first routed to the pyrolyzer via the Freon filter

before being sent to the gas sensor cartridge,

where the gas measurement is taken. The sample

continues via the flow meter through the dust

filter and is finally exhausted from the instrument.

Adjustment of the gas flow through the instrument

is done automatically. It is recommended to

perform a leak check (see Section 8.5) before

performing a flow calibration. To perform a flow

calibration refer to Section 7.3.3.

Diagram 9-3. Pyrolyzer conguration gas ow.

Pyrolyzer Heater

Pyrolyzer

Gas sample

Inlet

Gas sample

Exhaust

Pump

Freon

filter

Pressure sensor

Orifice

(Bypass flow)

Gas sensor

Loading...

Loading...