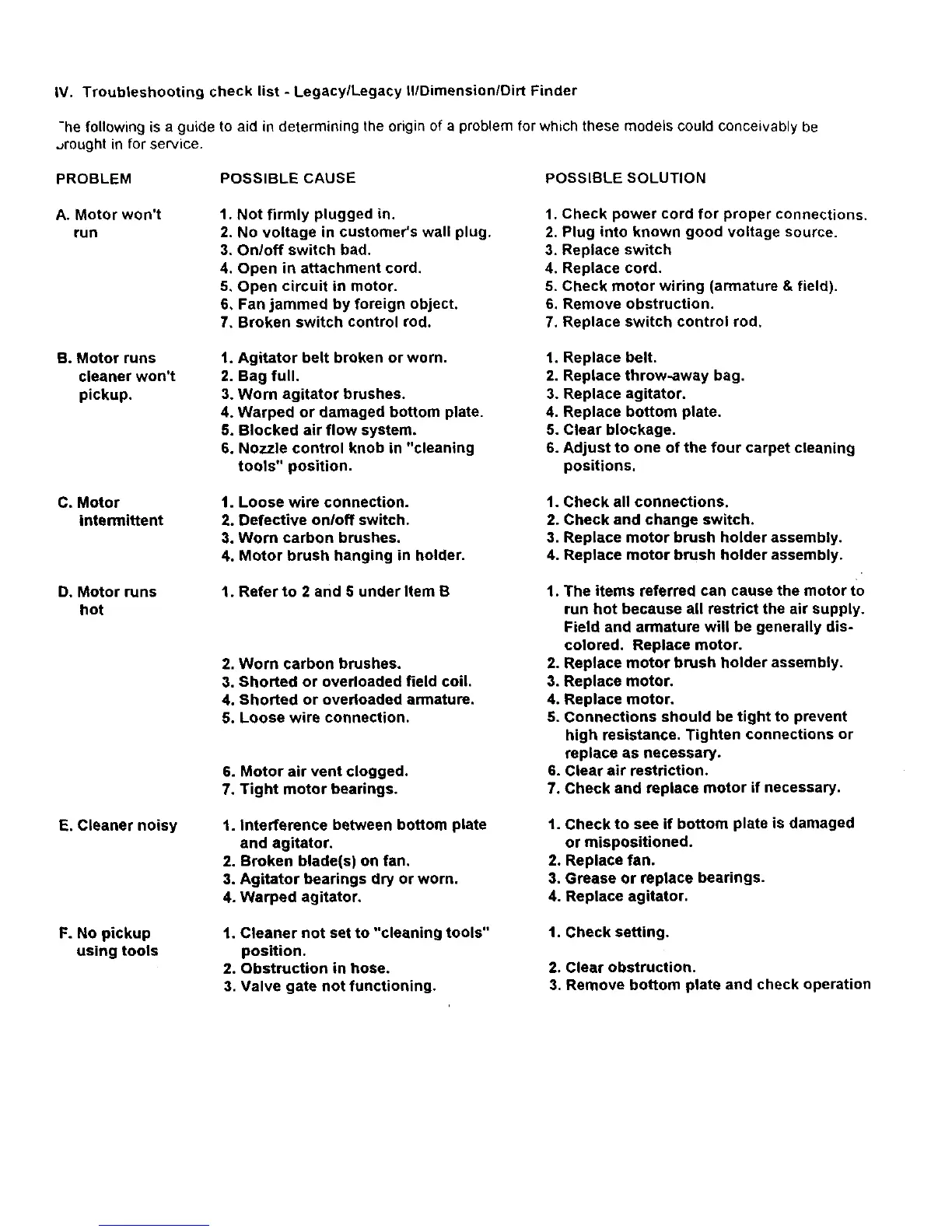

iV. Troubleshooting check list - Legacy/Legacy II/Dimension/Dirt Finder

-he following is a guide to aid in determining the origin of a problem for which these models could conceivably be

.Jrought in for service.

PROBLEM

POSSIBLE CAUSE POSSIBLE SOLUTION

A. Motor won't

run

1. Not firmly plugged in.

2. No voltage in customer's wall plug.

3, Onloff switch bad.

4. Open in attachment cord.

5, Open circuit in motor.

6, Fan jammed by foreign object.

7, Broken switch control rod.

1. Check power cord for proper connections.

2. Plug into known good voltage source.

3. Replace switch

4. Replace cord.

5. Check motor wiring (armature & field).

6. Remove obstruction.

7. Replace switch control rod,

B. Motor runs

cleaner won't

pickup.

1. Agitator belt broken or worn.

2. Bag full.

3. Worn agitator brushes.

4. Warped or damaged bottom plate.

5. Blocked air flow system,

6. Nozzle control knob in "cleaning

tools" position,

1. Replace belt.

2. Replace throw-away bag.

3. Replace agitator.

4, Replace bottom plate.

5. Clear blockage,

6. Adjust to one of the four carpet cleaning

positions.

C, Motor

intermittent

D. Motor runs

hot

1. Loose wire connection.

2. Defective onloff switch.

3. Worn carbon brushes.

4. Motor brush hanging in holder.

1. Refer to 2 and 6 under Item B

2. Worn carbon brushes.

3, Shorted or overloaded field coil.

4. Shorted or ovedoaded armature,

5. Loose wire connection.

6. Motor air vent clogged.

7, Tight motor bearings.

1. Check all connections.

2. Check and change switch.

3, Replace motor brush holder assembly.

4. Replace motor brush holder assembly.

1. The items referred can cause the motor to

run hot because all restrict the air supply.

Field and armature will be generally dis-

colored, Replace motor.

2. Replace motor brush holder assembly.

3. Replace motor,

4. Replace motor.

5. Connections should be tight to prevent

high resistance, Tighten connections or

replace as necessary.

6. Clear air restriction.

7. Check and replace motor if necessary.

E. Cleaner noisy t. interference between bottom plate

and agitator.

2. Broken blade(s) on fan,

3. Agitator bearings dry or worn.

4. Warped agitator,

1. Check to see if bottom plate is damaged

or mispositioned.

2. Replace fan.

3. Grease or replace bearings.

4. Replace agitator.

F. No pickup

using tools

1. Cleaner not set to "cleaning tools"

position.

2. Obstruction in hose.

3. Valve gate not functioning.

1. Check setting.

2. Clear obstruction.

3. Remove bottom plate and check operation

Loading...

Loading...