10 Troubleshooting

Linear actuators MC250 • MC253 • MC500 • MC503

32 Version 2.1 - March 2011 Operating Manual

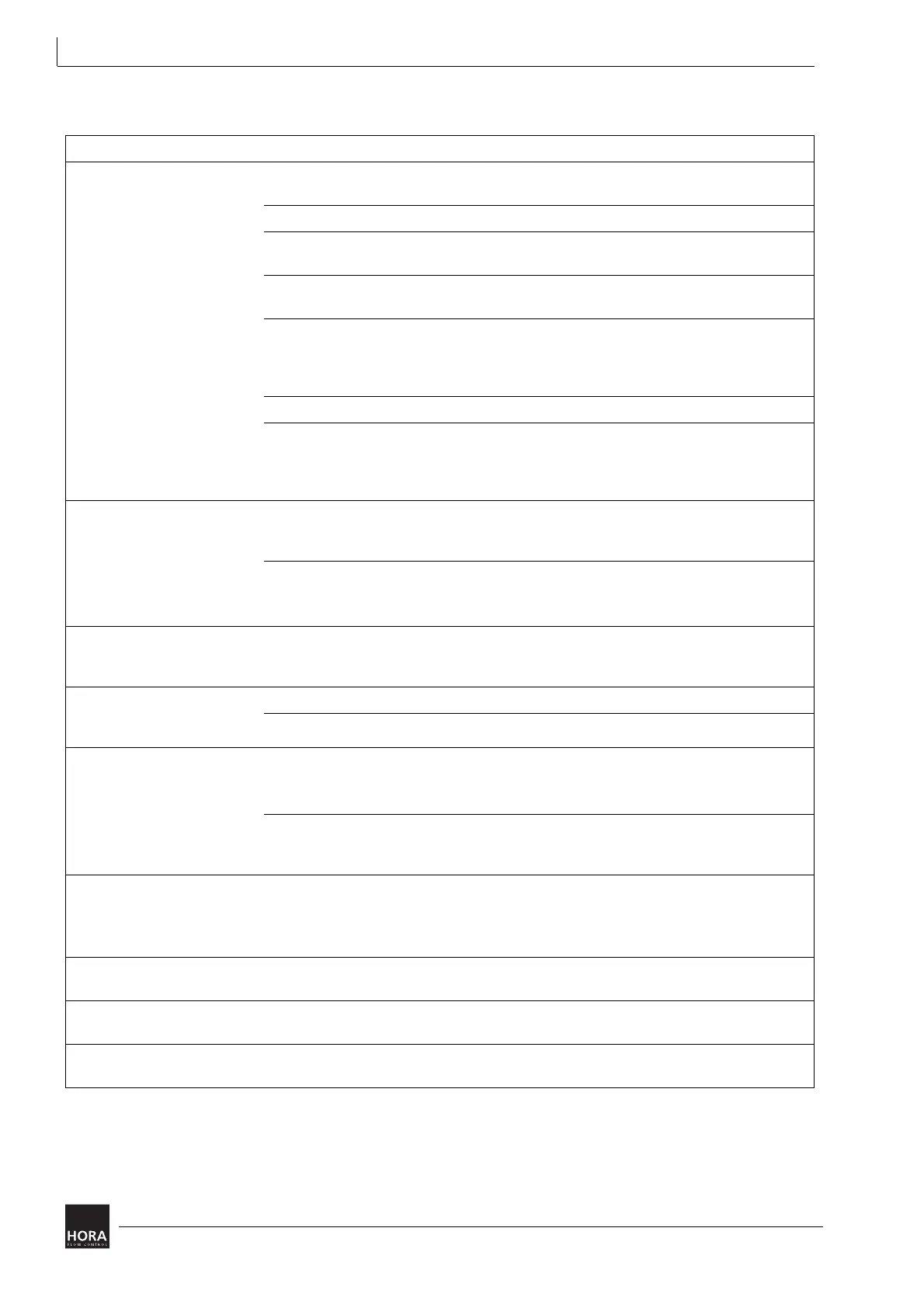

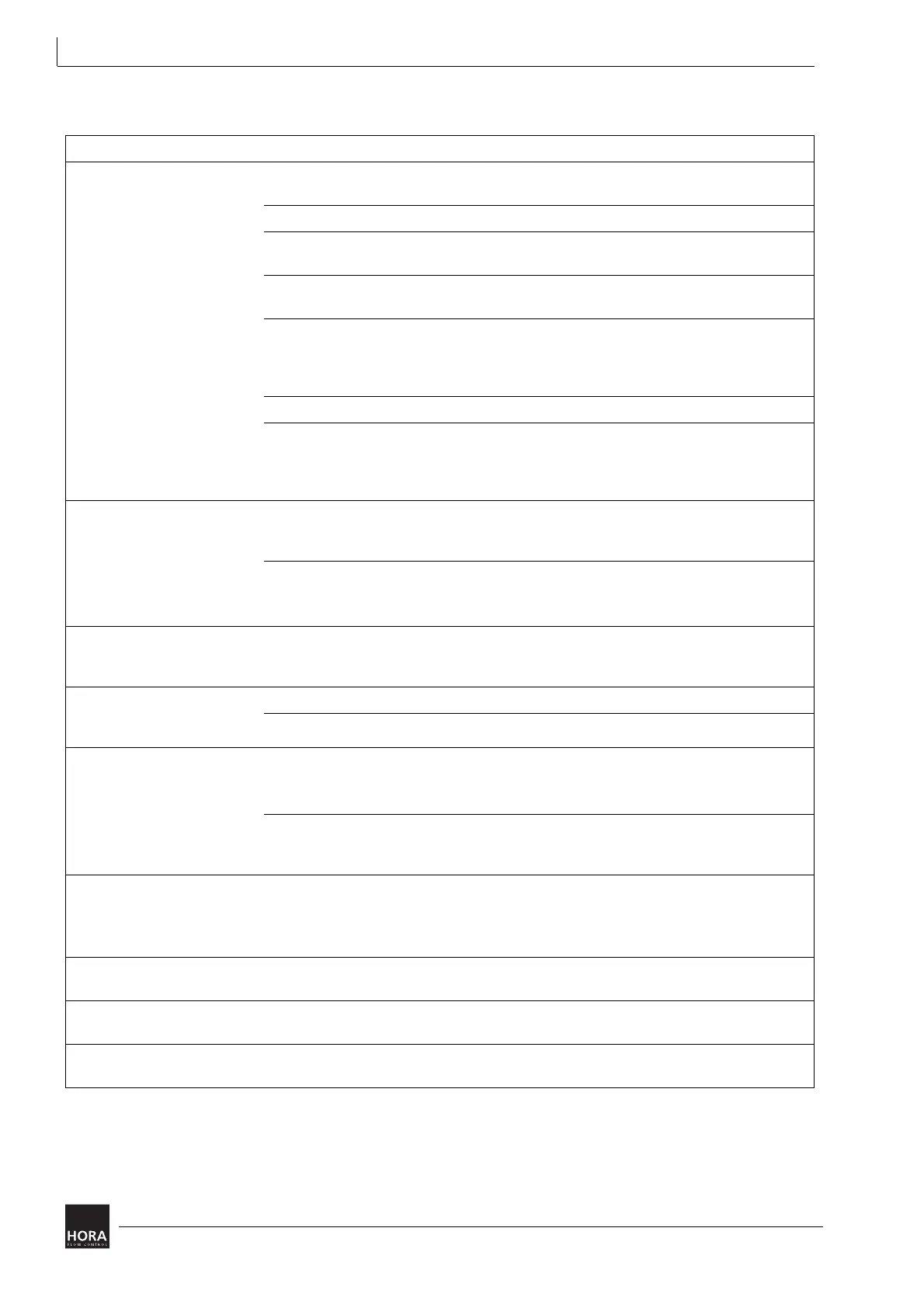

10.2 Operating faults checklist

Fault Cause/reason Remedy

1. Linear actuator does not

work.

Handwheel (36) is in manual mode position Switch handwheel to automatic mode

position.

Mains power failure Establish cause and eliminate.

Fuse defective. (in the electrical cabinet) Establish cause and eliminate, change

fuse.

Linear actuator incorrectly connected Rectify connection in accordance with

circuit diagram (on the cover).

Short circuit due to humidity Establish cause, dry the linear actuator,

change hood seal and screw

connections if necessary ad/or fit

protective hood.

Short circuit due to incorrect connection Rectify connection

Motor has coil damage (burnt out)

• e.g. due to too high voltage

• Electronic system defective

Establish cause, measure current data

Compare with rating plate and table,

Remove linear actuator and return to

manufacturer for repair.

2. Linear actuator runs in an

unstable manner, i.e.

switches between clockwise

and counter-clockwise

rotation.

Voltage drop due to too long connecting

cables and/or too small cross-section.

Measure linear actuator current data,

recalculate and change connecting

cables if necessary.

Mains power fluctuations greater than

permissible tolerance

2.5 Technical data on page 10

Improve mains power ratios

3. Linear actuator cuts out

from time to time or

initialises frequently.

Supply cable has loose contact Check and tighten connections (terminal

strips)

4. Linear actuator does not

move to the limit positions.

Valve does not close/open.

Valve jams Ensure smooth running valve

Too high system pressure Correct system pressure

5. Linear actuator does not

move or does not move

correctly to the position

specified by input signal Y.

Input signal Y faulty:

• Error signals

• Signal fluctuations

Check input signal Y on linear actuator,

eliminate cause of fault

Motherboard faulty Change motherboard, remove linear

actuator and return to manufacturer for

repair if necessary.

6. Green LED flashes in long /

long rhythm

Lock detection has responded Press INIT and observe actuator during

initialisation.

Check valve for smooth running over

entire lift range.

7. Greed LED flashes in short /

long rhythm

Open circuit detected Measure reference value voltage or

current on linear actuator.

8. Green LED flashes in long /

short rhythm

Relay contact adherence

Check control

9. Red LED flashes regularly Actuator overheats Motor has switched off automatically.

Automatic start-up after cooling down

Table 9 Operating faults checklist

Loading...

Loading...