4

EngineeringGuidelines

Thisfiltrationwillalsoreducesupplywater

relatedserviceproblemsifchangedatleast

everysixmonthsordependinguponlocalwater

conditions.

Adedicated1/2”ODScoppercoldwatersupply

shouldbelocatedwithin4feetoftheIceFlaker

completewithhandshutoffvalve.

A3/8”ODcopper

tubeshouldconnectthefield

installedshutoffvalvewiththeIceFlakerwater

inletconnectionlocatedattherearofthe

machine.

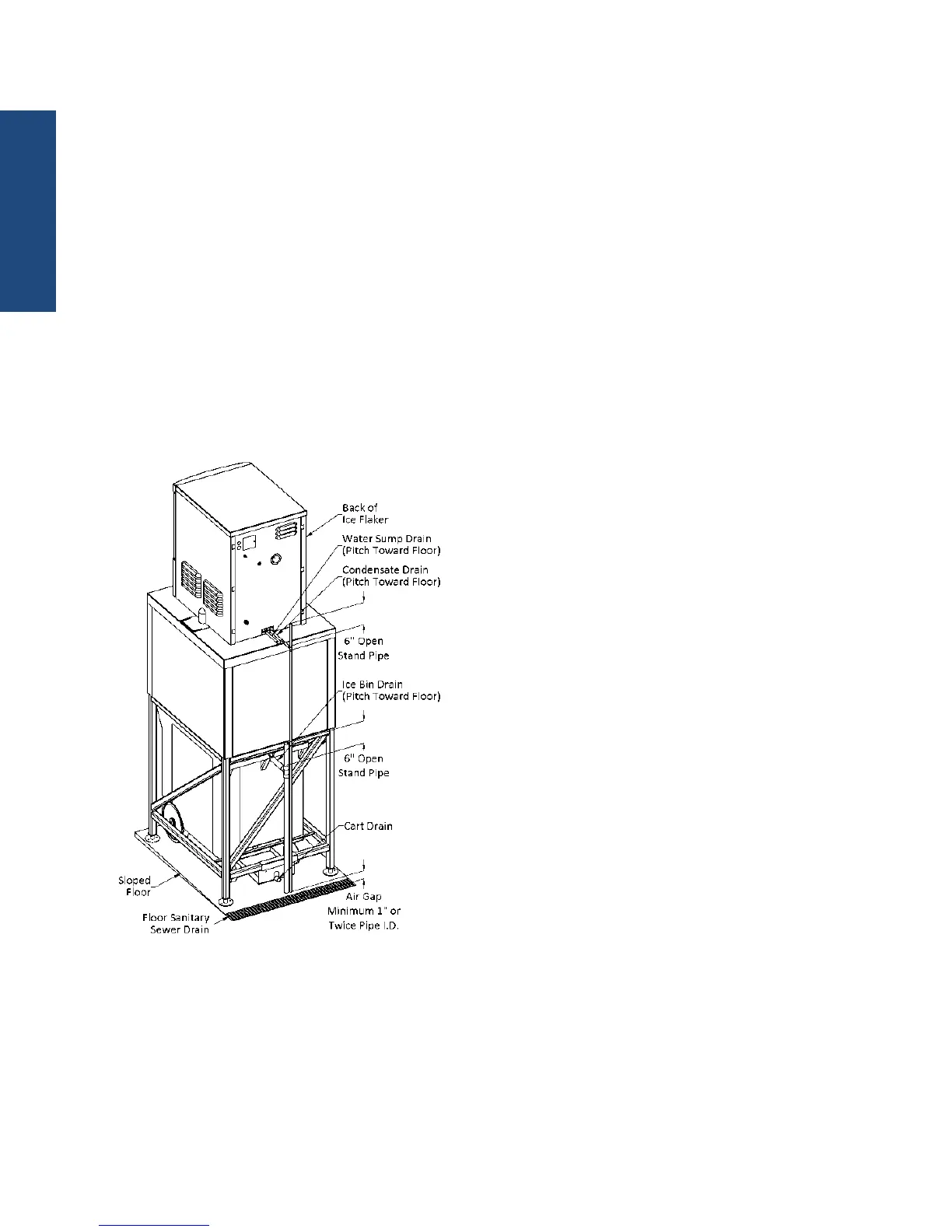

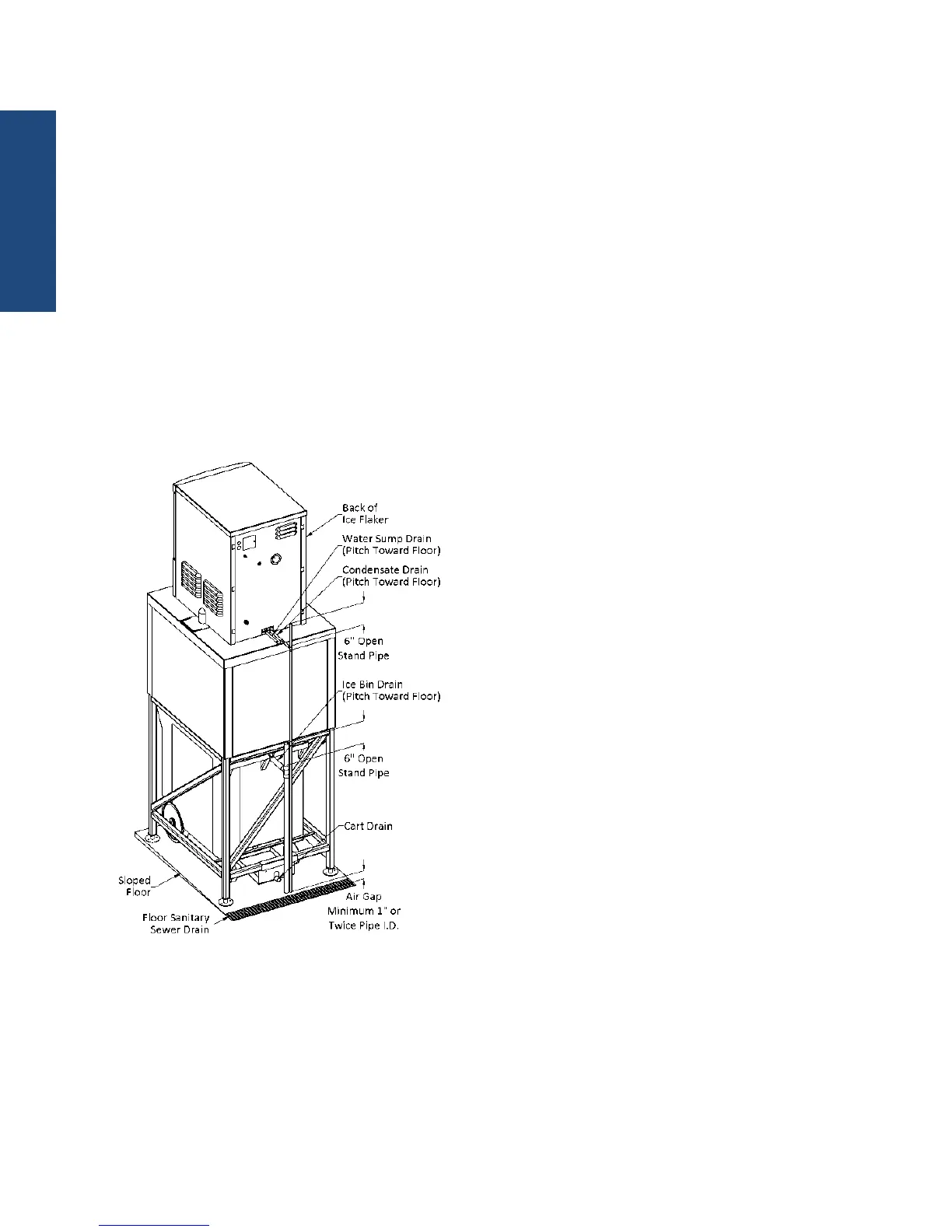

DrainWaterPipingRequirements

TheDrainWaterPipingfigureaboveillustrates

therecommendedpipingtoafloorsanitary

sewerhubortrenchdrain.Thetwovertical

pipedropsshoulddrainwaterthroughan

indirectwaterconnectionwithan“AirGap”.

Codeauthoritieshavingjurisdictionmaydictate

otherindirectwaterconnectionrequirements.

Thefiguredepicts

twoseparatedrainlines

whicharerequiredtoensuretheIceFlaker

doesnotinadvertentlyflowWaterSumpDrain

waterintotheIceBinorCartsintheeventofa

backuporanyothermalfunction.

ElectricalRequirements

Adedicated15amp,2pole,208‐230voltpower

supplyfromafieldfurnishedandinstalled

disconnectswitchisrequiredforeachIce

Flaker.

Adedicated3pole,208‐230voltpowersupply

fromafieldfurnishedandinstalleddisconnect

switchisrequiredforeachRemoteCondensing

Unit.Theamperage

ofthepowersupplycircuit

mustmatchtheselectedRemoteCondensing

UnitsuppliedbyHowewithrespectto

MinimumCircuitAmperage(MCA)and

MaximumOvercurrentProtectionDevice

(MOPD)nameplateinformation.

Atwoconductorcontrolcircuitisrequiredto

interconnecttheIceFlakerwiththeRemote

CondensingUnitinterlockingrelay.

Loading...

Loading...