LP-605 Rev. 000 Rel. 009 Date 8.16.18

51

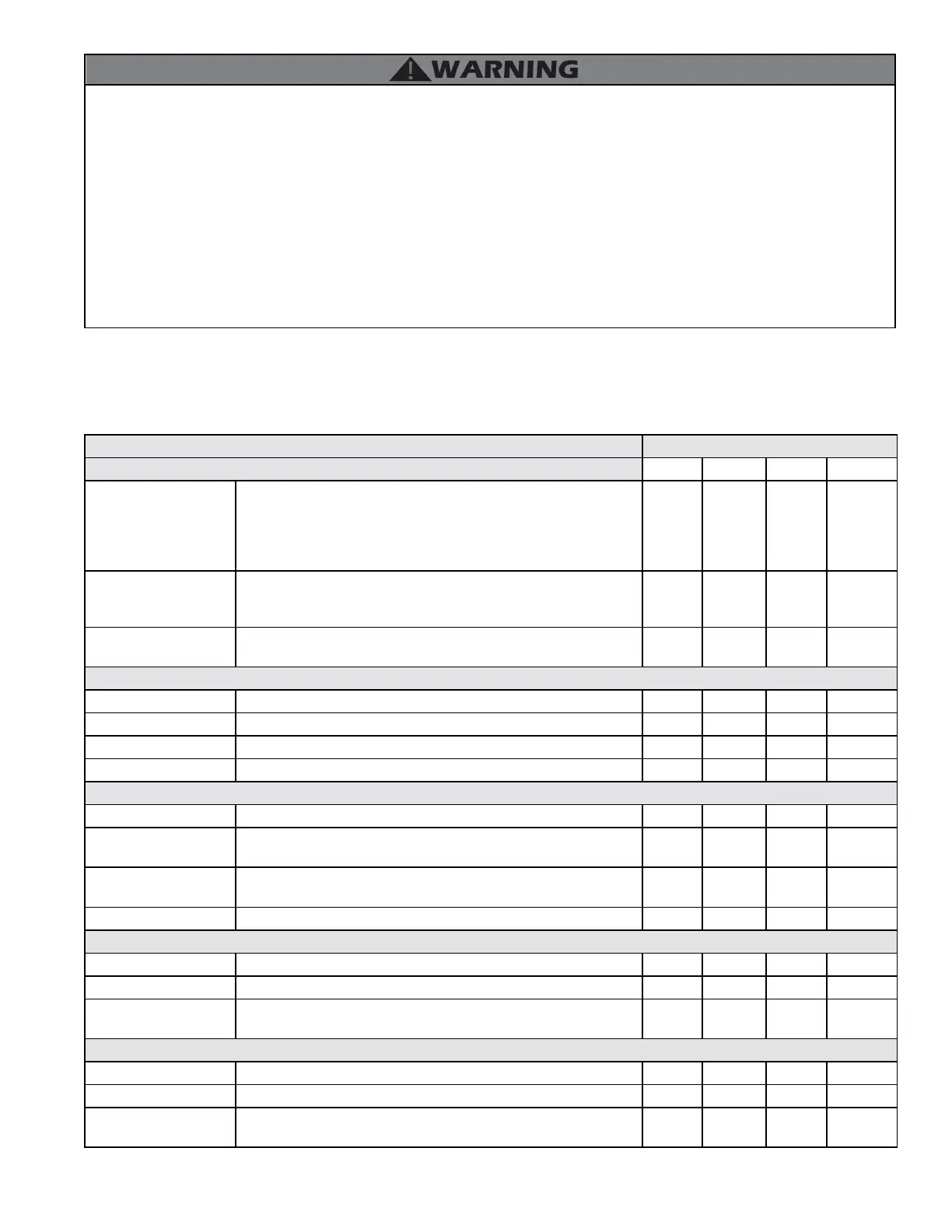

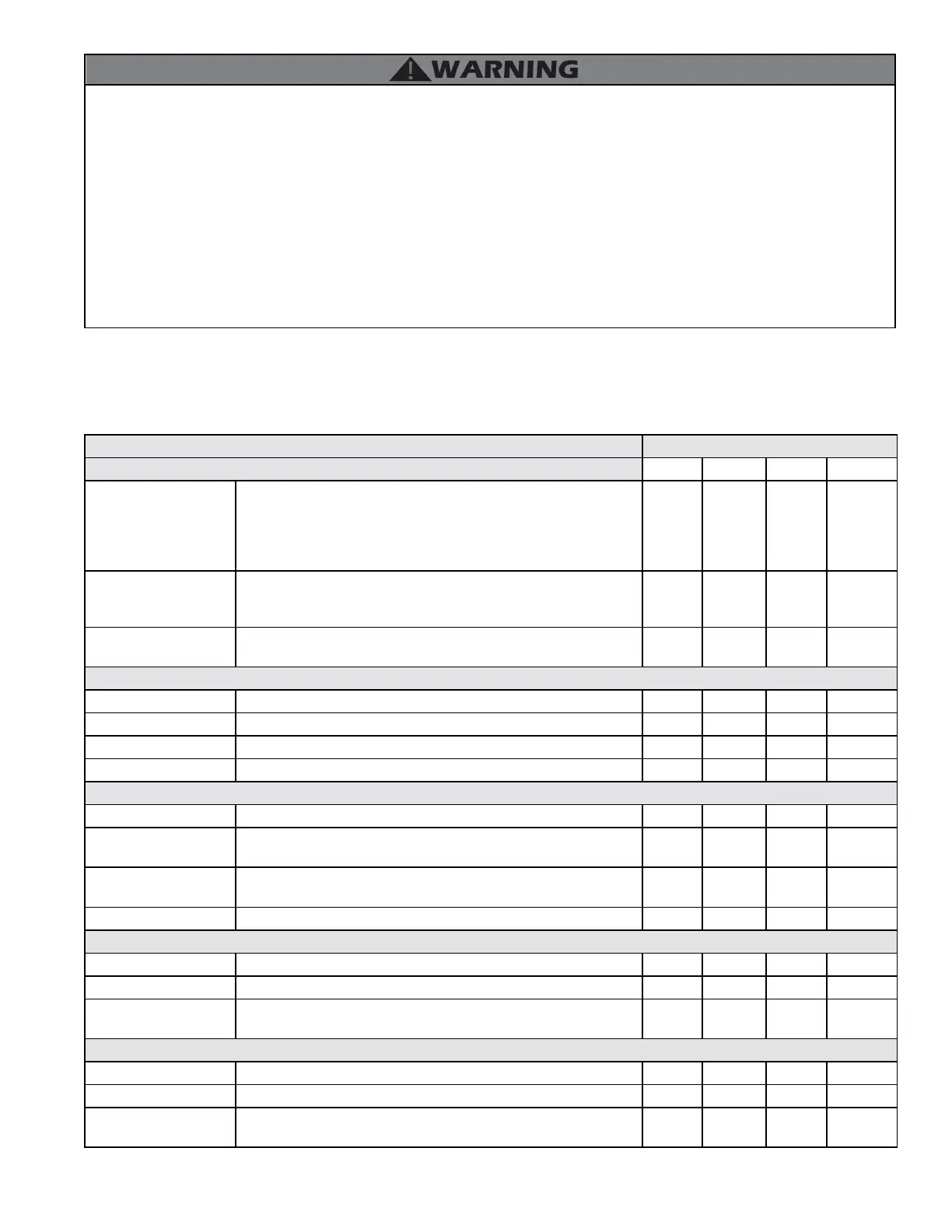

INSPECTION ACTIVITIES DATE LAST COMPLETED

PIPING

1

st

YEAR 2

nd

YEAR 3

rd

YEAR 4

th

YEAR*

Near water heater

piping

Check water heater and system piping for any sign of leakage.

Leaking pipes could cause property damage. Make sure all piping

is properly supported. Flush tankless heat exchanger annually

(more in hard water conditions). See User’s Information manual for

instructions.

Vent Check condition of all vent pipes and joints. Ensure all vent piping

is properly supported. Check for obstructions exhaust and intake

termination points.

Gas Check Gas piping, test for leaks and signs of aging. Make sure all

pipes are properly supported.

SYSTEM

Visual Do a full visual inspection of all system components.

Functional Test all functions of the system (Heat, Safeties)

Temperatures Verify safe settings on water heater or Anti-Scald Valve

Temperatures Verify programmed temperature settings

ELECTRICAL

Connections Check wire connections. Make sure they are tight.

Smoke and CO detector Verify devices are installed and working properly. Change batteries

if necessary.

Circuit Breakers Check to see that the circuit breaker is clearly labeled. Exercise circuit

breaker.

Plug Verify that the power plug is functional and ground prong is intact.

CONDENSATE

Condensate Trap Clean debris from the condensate trap. Fill with clean water.

Neutralizer Check condensate neutralizer. Replace if necessary.

Condensate Pipe Verify the ow of condensate, making sure that condensate ows

properly

GAS

Pressure Measure incoming gas pressure (3.5” to 14” W.C.)

Pressure Drop Measure drop in pressure on light o (no more than 1” W.C.)

Check gas pipe for

leaks

Check piping for leaks. Verify that all are properly supported.

The combustion chamber insulation in this product contains ceramic ber material. Ceramic bers can be converted to cristobalite in very

high temperature applications. The International Agency for Research on Cancer (IARC) has concluded, “Crystalline silica inhaled in the form

of quartz or cristobalite from occupational sources is carcinogenic to humans (Group 1).”

• Avoid breathing dust and contact with skin and eyes.

• Use a NIOSH certied dust respirator (N95). This type of respirator is based on the OSHA requirements for cristobalite at the time this

document was written. Other types of respirators may be needed depending on job site conditions. Current NIOSH recommendations

can be found on the NIOSH website: http://www.cdc.gov/niosh/homepage.html. NIOSH approved respirators, manufacturers, and

phone numbers are also listed on this website.

• Wear long-sleeved, loose tting clothing, gloves, and eye protection.

• Apply enough water to the combustion chamber lining to prevent dust.

• Wash potentially contaminated clothes separately from other clothing. Rinse clothes washer thoroughly.

NIOSH stated First Aid.

• Eye: Irrigate immediately.

• Breathing: Fresh air.

The water heater requires minimal periodic maintenance under normal conditions. However, in unusually dirty or dusty conditions, periodic

vacuuming of the cover to maintain visibility of the display and indicators is recommended.

Periodic maintenance should be performed once a year by a qualied service technician to assure that all the equipment is operating safely

and eciently. The owner should make necessary arrangements with a qualied heating contractor for periodic maintenance of the water

heater. Installer must also inform the owner that the lack of proper care and maintenance of the water heater may result in a hazardous

condition.

Loading...

Loading...