10

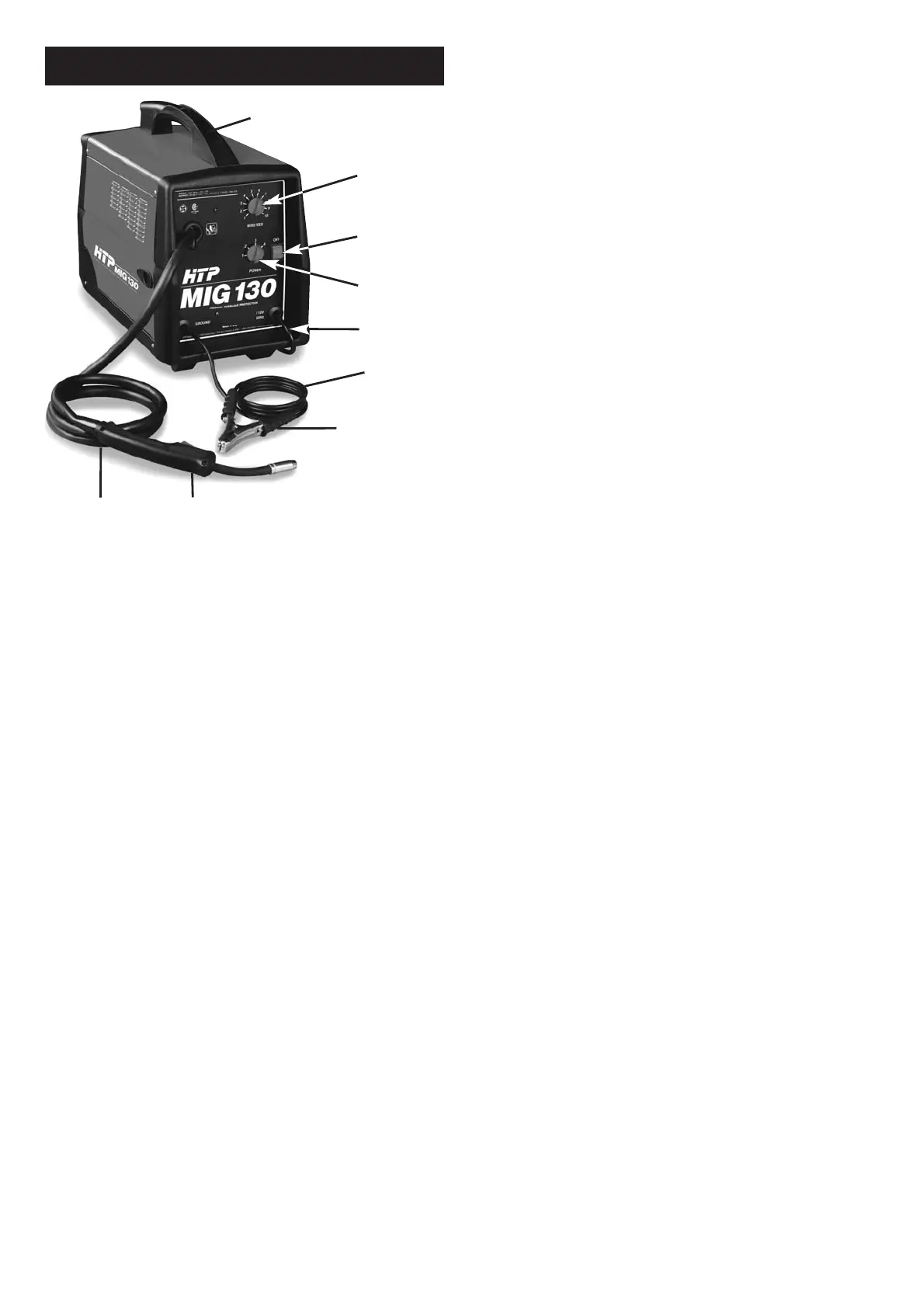

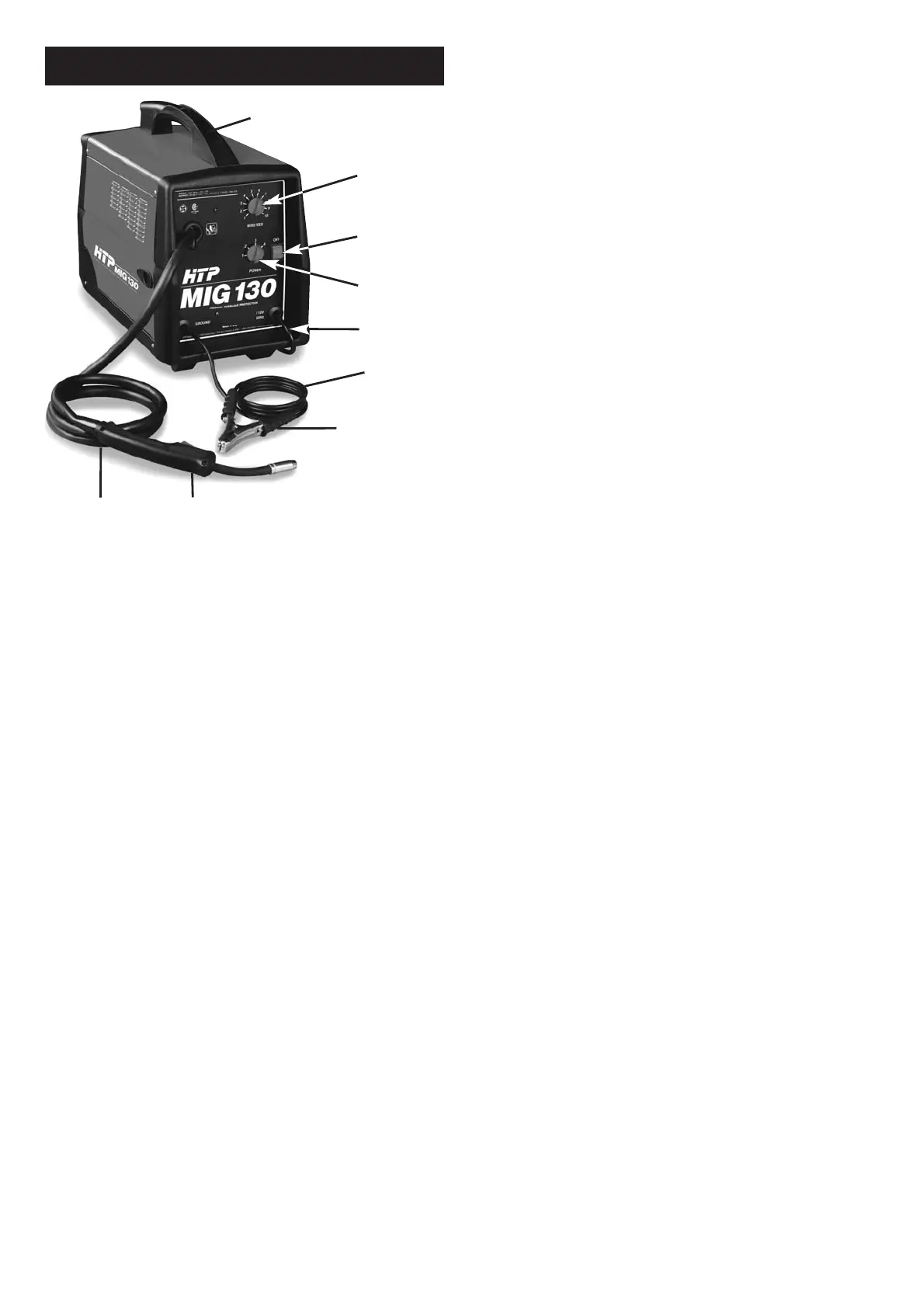

KNOW YOUR WELDER

Handle – Rugged, top mounted handle

allows for easy transport of your welder.

Wire Speed Control – Use this dial to adjust

the speed at which the welder feeds wire to

the gun. 1 is the slowest wire feed speed, 10 is

the highest. You will need to adjust or “tune-

in” your wire speed for different welding con-

ditions (thickness of metals, gas -vs- gasless

welding, metal type, wire size, etc.). When the

wire speed is properly “tuned-in” the welding

wire will melt into the material you are weld-

ing as quickly as it is fed through the welding

gun.

Voltage Selector – This four position dial

adjusts the voltage or “heat” of your welder. 1

is the lowest and 4 is the highest. Different

materials and material thickness will require

different voltage settings. You will need to

adjust your voltage accordingly for different

welding conditions. By properly adjusting

your voltage settings and wire feed speed,

you will enable clean, precision welds. (Refer

to the Suggested Settings Chart on p.33 of

this manual OR on the inside of the door of

the welder.)

Power Switch – This switch turns the welder

ON and OFF. (Make sure the power switch is

in the OFF position before performing any

maintenance on the welder.)

Power Cord – This is a standard, grounded

120 volt power cord. (Make sure you are

using a properly grounded 120 VAC, 60Hz,

single phase, 20 amp power source.)

Ground Clamp – Attaching the ground

clamp to your work piece “completes” the

welding current circuit. You must attach the

ground clamp to the metal you are welding.

If the ground clamp is not connected to the

metal work piece you intend to weld, the

welder will not have a completed circuit and

you will be unable to weld. A poor connec-

tion at the ground clamp will waste power

and heat. Scrape away dirt, rust, scale, oil or

paint before attaching the ground clamp.

Ground Cable – The ground cable connects

the ground clamp to the internal workings of

the welder.

Welding Gun and Cable – The welding gun

controls the delivery of the welding wire to

the material to be welded. The welding wire

is fed through the welding cable and welding

gun when the welding gun trigger is pulled.

You will need to install a contact tip and

welding nozzle to the end of the welding

gun, as described later in this manual, prior to

welding.

Welding Terms

Now that you are familiar with the main parts

of the welder, make note of the following

terms. You will see them used throughout

this manual.

weld puddle: The localized volume

of molten metal in a weld prior to its

solidification.

weld angle: The angle of the welding wire, as

it extends from the welding gun, in relation

to the item being welded.

slag: The protective coating that forms on

the surface of molten metal.

arc: A sustained luminous discharge of elec-

tricity across a gap in a circuit.

welding bead: The extended build up of a

weld, made by pushing or pulling the weld

Figure 1. Model HTP MIG 130

Welding

Gun

Ground

Clamp

Power

Cable

Ground

Cable

Voltage

Selector

Power

Switch

Wire

Speed

Gun Cable

Handle

Loading...

Loading...