14

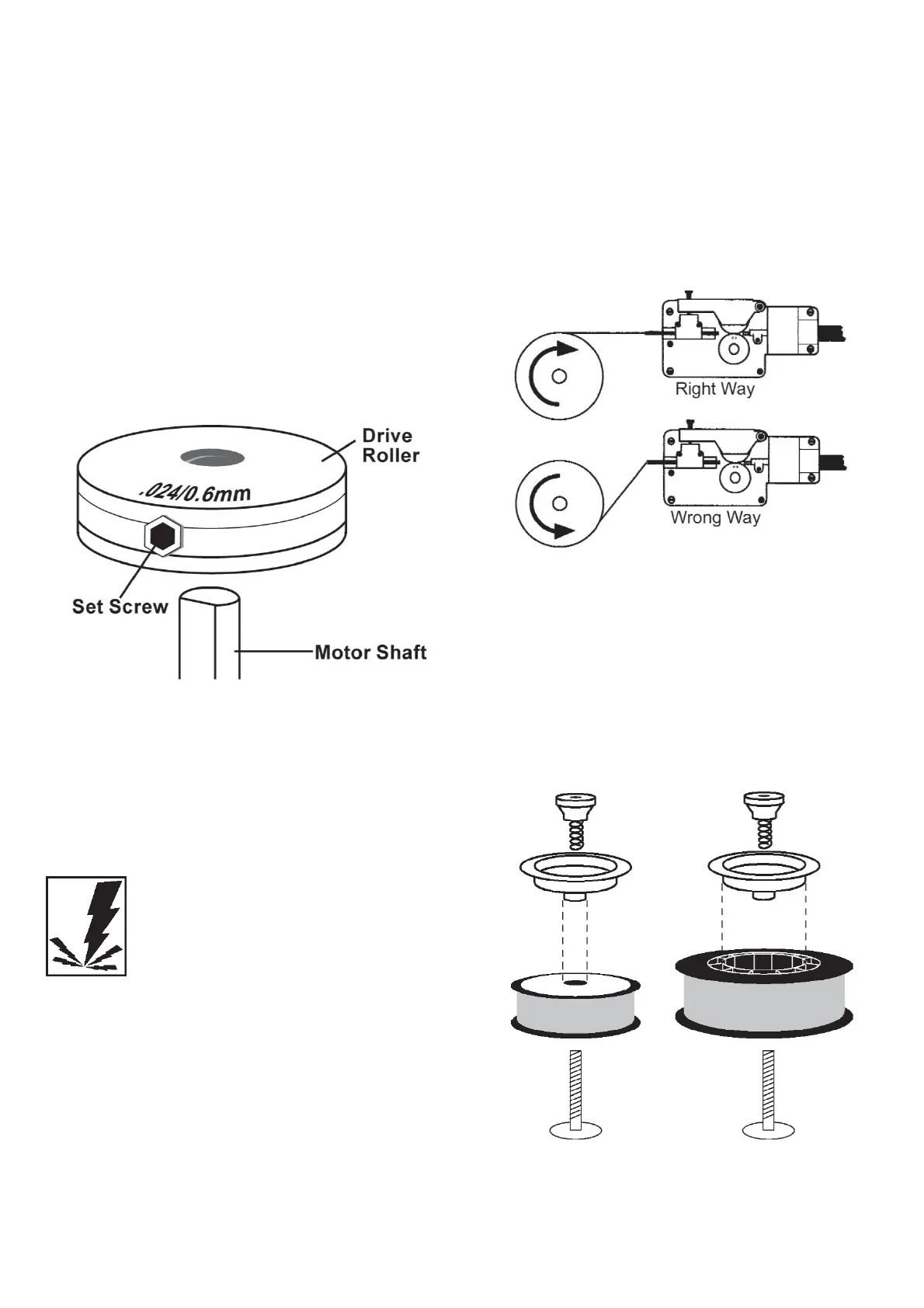

Note: The drive roller has two wire size grooves

built into it. When installing the drive roller the

number stamped on the drive roller for the

wire size you are using should be facing away

from you. If you can read the wire size you are

using on the drive roller, it is installed back-

wards. Use only the proper size drive roller

when using your welder.

4. Find the side of the drive roller that is

stamped with the same wire diameter as

that of the wire being installed (see Figure

4, and if in metric, see DESCRIPTION). Push

the drive roller onto the motor shaft, align-

ing the set screw with the flat side of the

drive shaft. Make sure the side stamped

with the desired wire diameter is away

from you.

5. Slide the roller onto the shaft so that the

groove in the roller lines up with the inlet

tube and the welding gun liner.

6. Tighten the set screw, while holding the

drive roller in place.

INSTALL THE WELDING WIRE

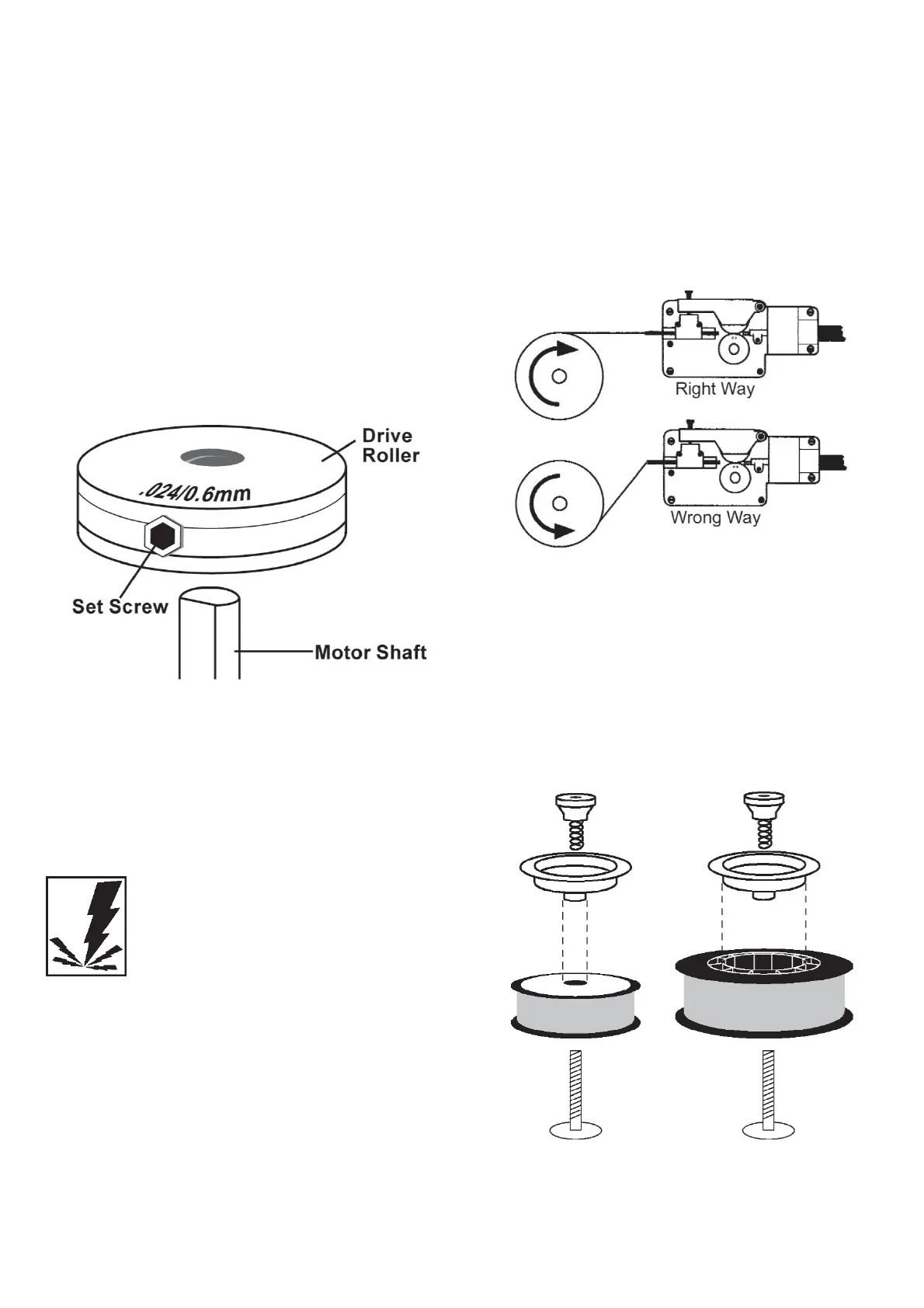

WARNING

Electric shock can kill! Always turn the POWER

switch OFF and unplug the power cord from

the ac power source before installing wire.

1. Remove the nozzle and contact tip from

the end of the gun assembly.

2. Make sure the proper groove on the drive

roller is in place for the wire being installed.

If the proper groove is not in place, change

the drive roller as described above.

3. Unwrap the spool of wire and then find the

leading end of the wire (it goes through a

hole in the outer edge of the spool and is

bent over the spool edge to prevent the

wire from unspooling), BUT DO NOT

UNHOOK IT YET.

4. Place the spool on the spindle in such a

manner that when the wire comes off the

spool, it will look like the top illustration in

Figure 5. The welding wire should always

come off the top of the spool into the drive

mechanism.

5. If you are installing a four-inch spool of

wire, install the drive brake hardware on

the top of the spool of wire according to

figure 6A. If you are installing an eight-inch

spool, install the spindle adapter and drive

brake hardware as shown in Figure 6B. The

purpose of the drive brake is to cause the

spool of wire to stop turning at nearly the

same moment that wire feeding stops.

Figure 4. Drive Roller

Figure 5. Wire Installation

Figure 7A. Drive

Brake Hardware

Installation

Figure 7B. Spindle

Adapter and Drive

Brake Installation

Loading...

Loading...