16

SET THE WIRE DRIVE TENSION

WARNING

To reduce the risk of arc flash, make certain

that the wire coming out of the end of the

gun does not come in contact with work

piece, ground clamp or any grounded materi-

al during the drive tension setting process or

arcing will occur.

1. Pull the trigger on the gun.

2. Turn the drive tension adjustment knob

clockwise, increasing the drive tension

until the wire seems to feed smoothly

without slipping.

When set correctly, there should be no slip-

page between the wire and the drive roller

under normal conditions. If an obstruction

occurs along the wire feed path, the wire

should then slip on the drive roller.

After the tension is properly adjusted, the

quick release drive tensioner may unlocked

and relocked and no radjustment of the drive

tension adjustment knob will be necessary

(unless the diameter or type of wire is

changed).

INSTALLING ALUMINIUM WIRE

Install aluminium wire the same as steel wire,

but with the following exceptions:

1. Install a plastic liner (PN15044) in the

welding gun.

2. Adjust the drive tension VERY carefully.

Aluminium wire is very sensitive to slight

changes in drive tension.

Note: For welding aluminium with this unit,

5356 alloy wire is recommended because of

its superior feedability. A plastic liner is need-

ed. When welding with softer aluminium

alloys, you may experience feed problems.

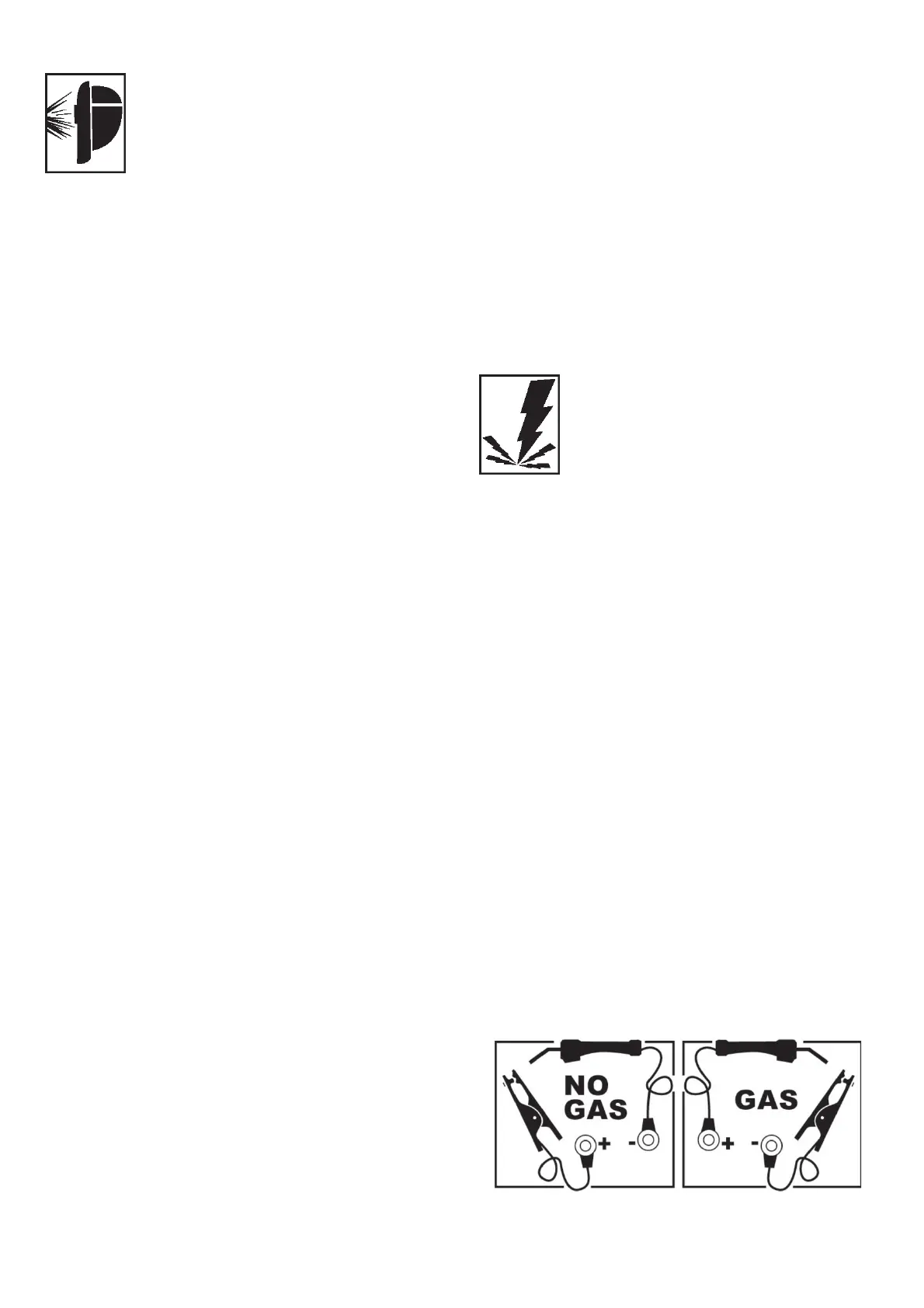

CHANGE POLARITY

This welder allows you to change the welding

current polarity. Select Straight Polarity for

welding with Flux Core Wire (FCAW). Select

Reverse Polarity for MIG welding (GMAW)

when using mild steel, stainless steel or sili-

con bronze wire. Reverse polarity is also sug-

gested with some flux core wire used in hard

facing.

Change the polarity of your welder according

to the following procedure steps. Figure 8

shows what the polarity block should look

like for each polarity setting.

WARNING

Electric shock can kill! Always turn the power

OFF and unplug the power cord from the ac

power source before changing polarity.

CAUTION

Do not use a ratchet, crescent or other lever

type wrench to tighten knobs on the polarity

block. The nuts must be hand tightened only.

Too much torque applied to one of the knobs

could cause the knob to break off.

1. Remove the retaining knobs from the +

and - mounting posts on the Gas/No Gas

Board, located just below the drive motor

on the inside of your welder.

A. For Gasless (FCAW) welding, mount the

Ground Clamp ring terminal to the “+”

mounting post and the Torch ring ter-

minal to the “-”mounting post.

B. For MIG (GMAW) welding, mount the

Ground Clamp ring terminal to the “-”

mounting post and the Torch ring ter-

minal to the “+” mounting post.

See configuration shown in Figure 7.

Figure 7. Changing Polarity

Loading...

Loading...