12

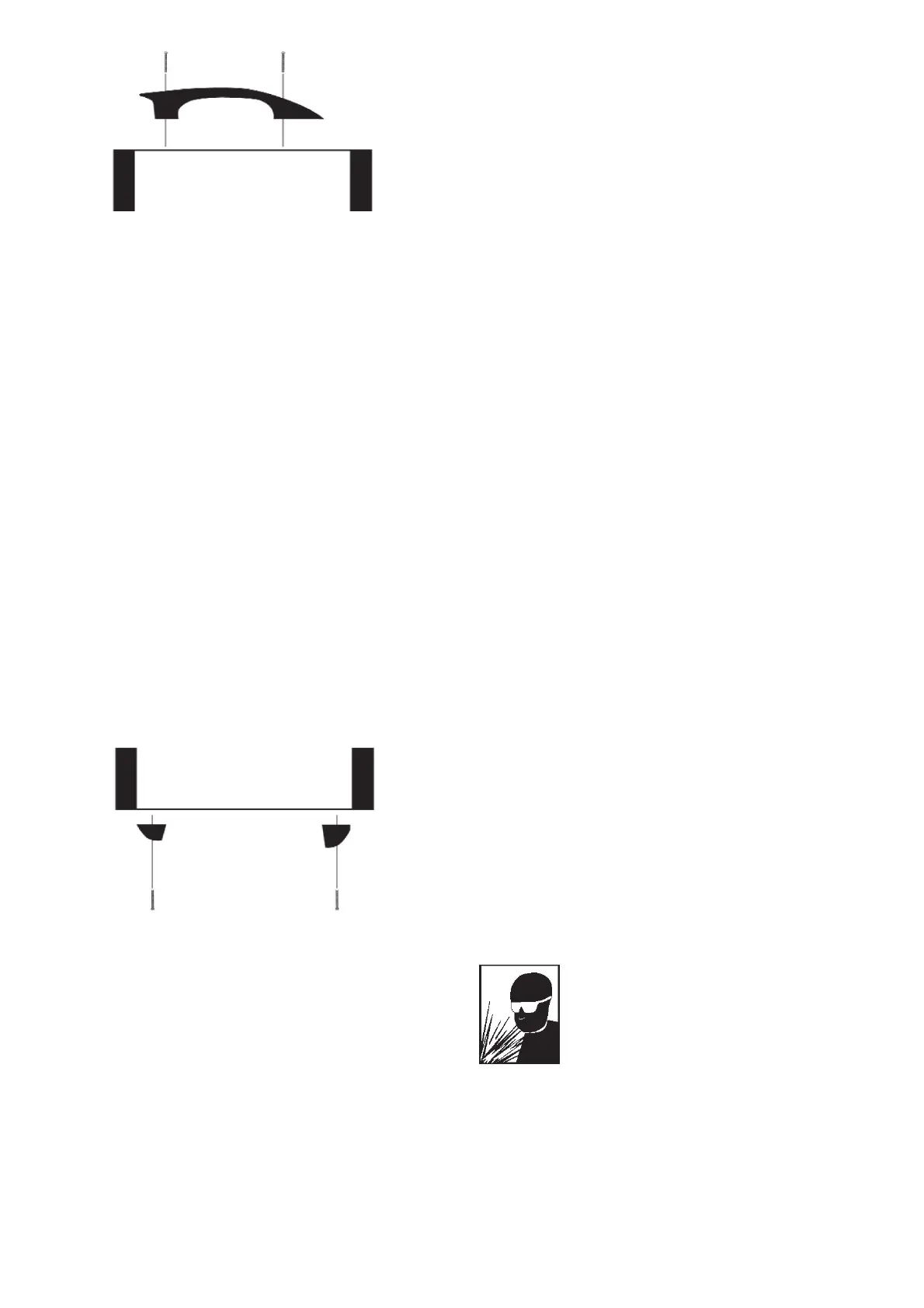

INSTALLING THE FEET

Locate the two black plastic feet for the

welder. (The front feet are slightly larger than

the back feet.)

1. Lay the welder on its side.

2. Align the holes of the front feet with the

front screw holes on the bottom of the

welder. The curved face of the front feet

should face the front of the welder.

3. Insert the two Phillips head screws (includ-

ed in the accessories bag) into the holes.

4. With a Phillips head screwdriver, securely

tighten both screws.

5. Align the holes of the back feet with the

rear screw holes on the bottom of the

welder. The curved face of the back feet

should face the rear of the welder.

6. Insert the two Phillips head screws

(included in the accessories bag) into the

holes.

7. With a Phillips head screwdriver, securely

tighten both screws. (see Figure 3)

SELECTING SHIELDING GAS

The shielding gas plays an extremely impor-

tant role in the MIG welding process. It is criti-

cal that the molten weld puddle be shielded

from the atmosphere. The shielding gas cre-

ates a protective pocket around the weld

puddle which keeps impurities in the air from

contaminating the weld. Inadequate shield-

ing will result in porous, brittle welds.

Although there are many gasses and gas mix-

tures available for MIG welding, the following

recommendations are based on the electrical

output characteristics and metal thickness

capabilities of this specific MIG welder.

Gas Selection For Steel Welding With Steel

Wire

For either mild or low carbon (High Strength

Structural) steel, use a gas mixture of 75%

Argon and 25% Carbon Dioxide. DO NOT USE

Argon gas concentrations higher than 75% on

steel. The result will be extremely poor penetra-

tion, porosity, and brittleness of weld.

This gas mixture helps to prevent burn

through and distortion on very thin steel yet

provides good penetration on thicker steel.

Its ability to minimize spatter results in clean,

smooth weld appearances. In addition, it pro-

vides good puddle control when welding ver-

tically or overhead.

Gas Selection For Stainless Steel Welding

The best shielding gas for stainless steel

welding is a mixture of 90% Helium, 7.5%

Argon, and 2.5% Carbon Dioxide. However,

the 100% Argon, can also be used, but an

increase in the area being heated by the arc

will be experienced causing slightly greater

distortion of the base metal.

Gas Selection For Steel Welding With

Silicon Bronze Wire

Use only pure Argon when welding steel with

Silicon-Bronze wire.

Gas Selection For Aluminium Welding with

Aluminium Wire

Use only pure Argon when welding

Aluminium.

INSTALL THE SHIELDING GAS

WARNING

IMPROPER HANDLING AND MAINTENANCE

OF COMPRESSED GAS CYLINDERS AND REG-

ULATORS CAN RESULT IN SERIOUS INJURY OR

DEATH! Always secure gas cylinders to the

welding cart, a wall, or other fixed support to

prevent the cylinder from falling over and rup-

Figure 3. Feet Installation

Figure 2. Handle Installation

Loading...

Loading...