lp-65 Rev. 1.6.15

7

Do not thread a cap or plug into the relief valve or relief valve

line under any circumstances! Explosion and property damage,

serious injury, or death may result.

RE-INSPECTION OF T&P RELIEF VALVES: T&P valves should

be inspected AT LEAST ONCE EVERY THREE YEARS, and

replaced if necessary, by a licensed plumbing contractor or

qualied service technician to ensure that the product has

not been aected by corrosive water conditions and to ensure

that the valve and discharged line have not been altered or

tampered with illegally. Certain naturally occuring conditions

may corrode the valve and its components over time, rendering

the valve inoperative. Such conditions can only be detected

if the valve and its components are physically removed and

inspected. Do not attempt to conduct an inspection on your

own. Contact your plumbing contractor for a re-inspection to

assure continued safety.

FAILURE TO RE-INSPECT THE T&P VALVE AS DIRECTED

COULD RESULT IN UNSAFE TEMPERATURE AND/OR

PRESSURE BUILD-UP WHICH CAN RESULT IN PROPERTY

DAMAGE, SERIOUS PERSONAL INJURY, OR DEATH.

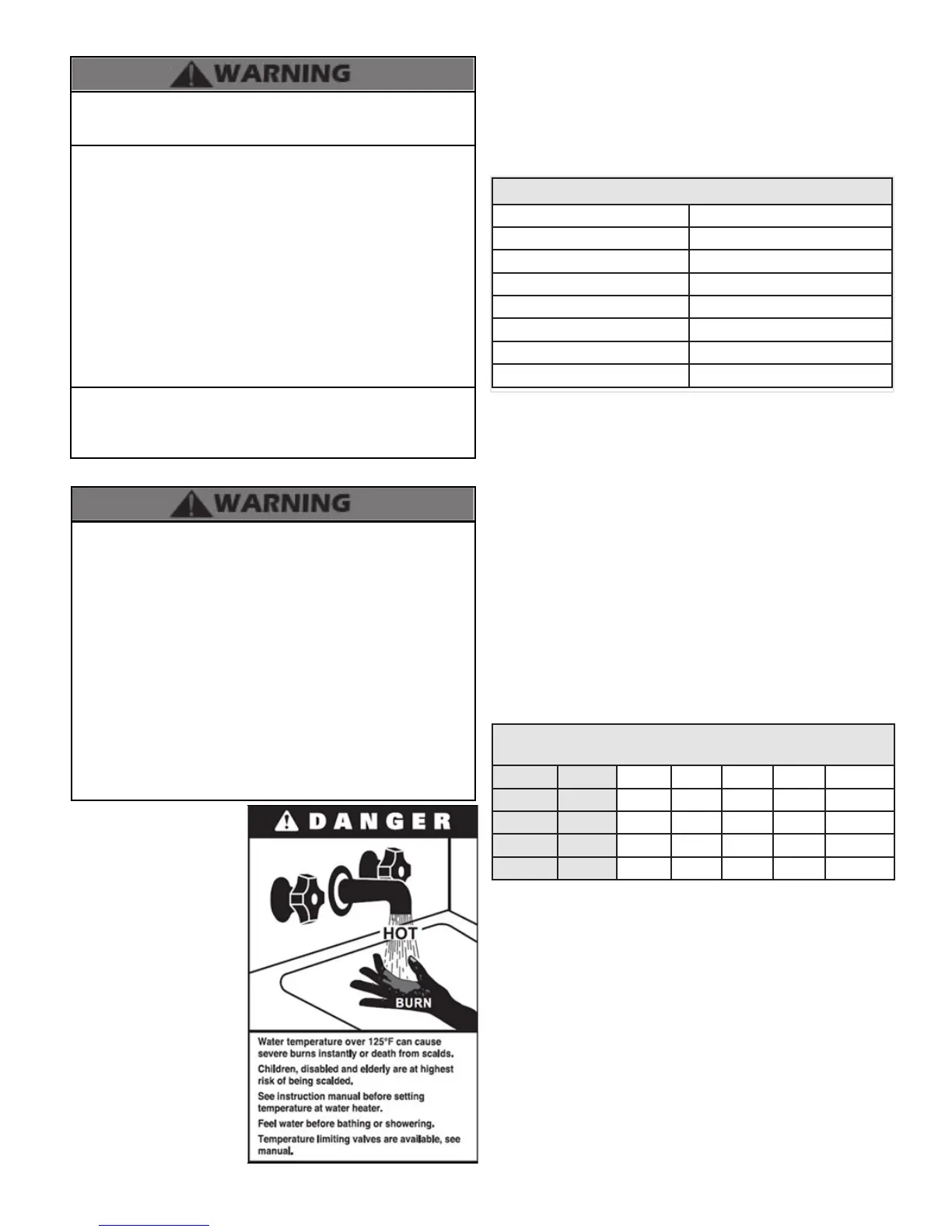

F. Scalding

An ASSE 1017 or ASSE 1070 temperature limiting or mixing

valve is recommended in installations servicing disabled or

elderly persons, or children. Mixing valves do not eliminate the

risk of scalding.

To avoid scalding:

• Set the water heater set point temperature as low as

possible.

• Feel water before bathing or showering.

• If thermostatic valves are required, use devices

specically designed for such purpose. Install these

devices in accordance with instructions provided by the

manufacturer.

Failure to install a temperature limiting or mixing valve and

follow these instructions could result in property damage,

severe personal injury, or death due to scalds.

This water heater can

deliver scalding water. Be

careful whenever using

hot water to avoid scalding

injury. Certain appliances

such as dishwashers and

automatic clothes washers

may require increased

water temperatures. By

setting the thermostat

on this heater to obtain

the increased water

temperature required by

these appliances you may

create the potential for

scald injury.

To protect against injury,

install a mixing valve in the

water system. This valve

Approximate Time / Temperature Relationships in Scalds

120

o

F More than 5 minutes

125

o

F 1 1/2 to 2 minutes

130

o

F About 30 seconds

135

o

F About 10 seconds

140

o

F Less than 5 seconds

145

o

F Less than 3 seconds

150

o

F About 1 1/2 seconds

155

o

F About 1 second

Table 3 - Approximate Time / Temperature Relationships in Scalds

G. Potable Expansion Tank

A potable hot water expansion tank may be required to oset

heated water expansion. If there is a back ow preventer or any

other type of no return or check valve in the system a thermal

expansion tank IS MANDATORY. The expansion tank must be

sized for the entire water volume of the hot water system. A

weeping relief valve indicates the need for an expansion tank.

See the Typical Expansion Tank example in the Piping section for

details.

will reduce point of use discharge temperatures by mixing cold

and hot water in branch supply lines. Such valves are available

from your local plumbing supplier.

The following table details the relationship of water temperature

and time with regard to scald injury and may be used as a guide in

determining the safest water temperature for your applications.

H. Pressure Drop Sizing For Circulator

The boiler circulator ow rate must meet the requirements

found in the pressure drop sizing chart. The chart represents the

pipe run, water heater, and heat exchanger ONLY and does not

include any ow checks, zone valves, or friction loss through the

boiler. That resistance must be added to the value found in the

following chart.

Pressure Drop for Pipe Length of 1” Copper,

Six 90

o

Elbows, and One Tee

Model 20’ 30’ 40’ 50’ 60’

SSC-35 8 GPM 6.28 6.53 6.78 6.28 7.28

SSC-50 8 GPM 6.48 6.73 6.98 7.23 7.48

SSC-80 10 GPM 6.19 6.55 6.85 7.15 7.45

SSC-119 12 GPM 16.19 16.79 17.39 17.99 18.59

Table 4 - Pressure Drop through 1” and 1 1/4” Copper

Loading...

Loading...