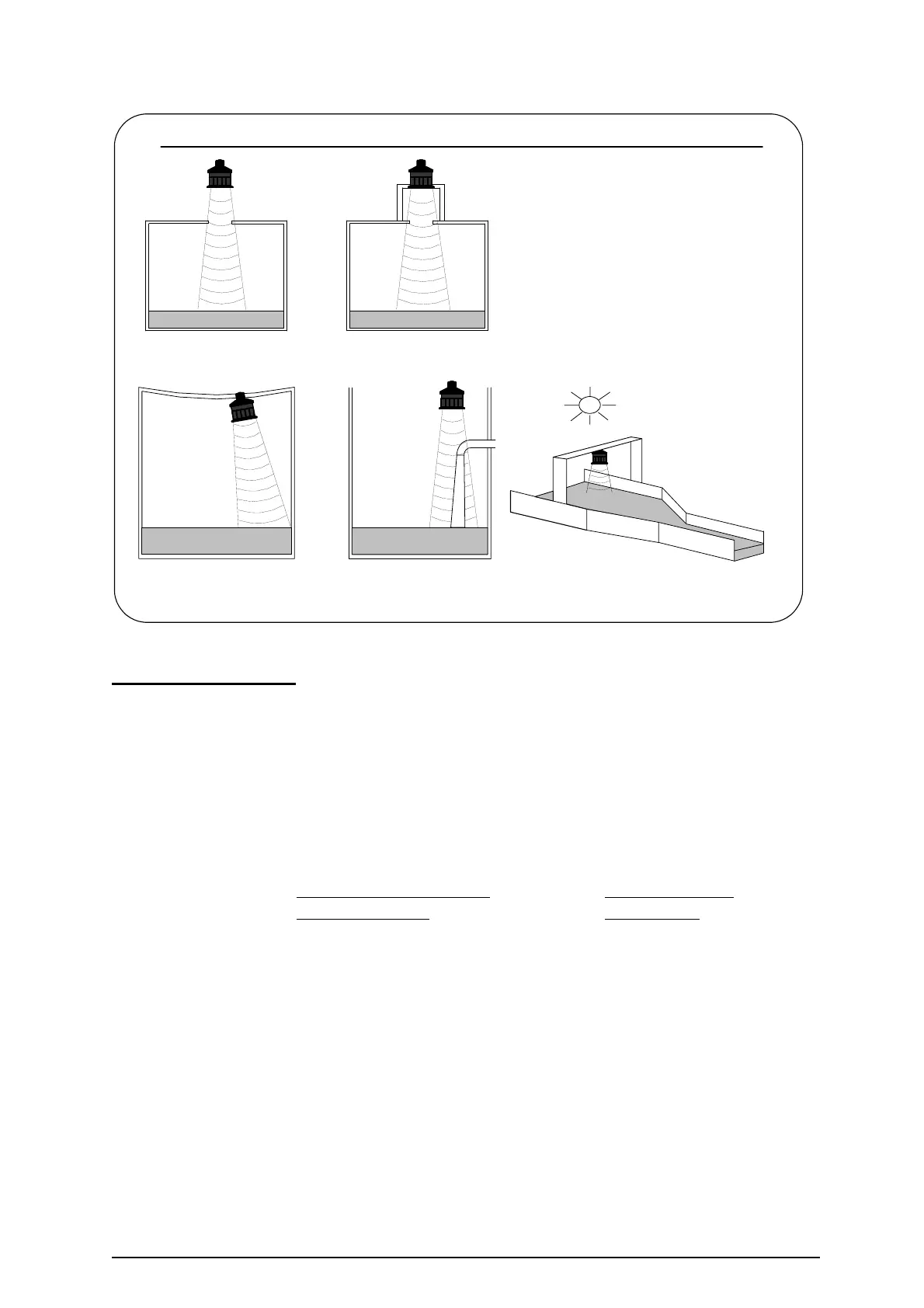

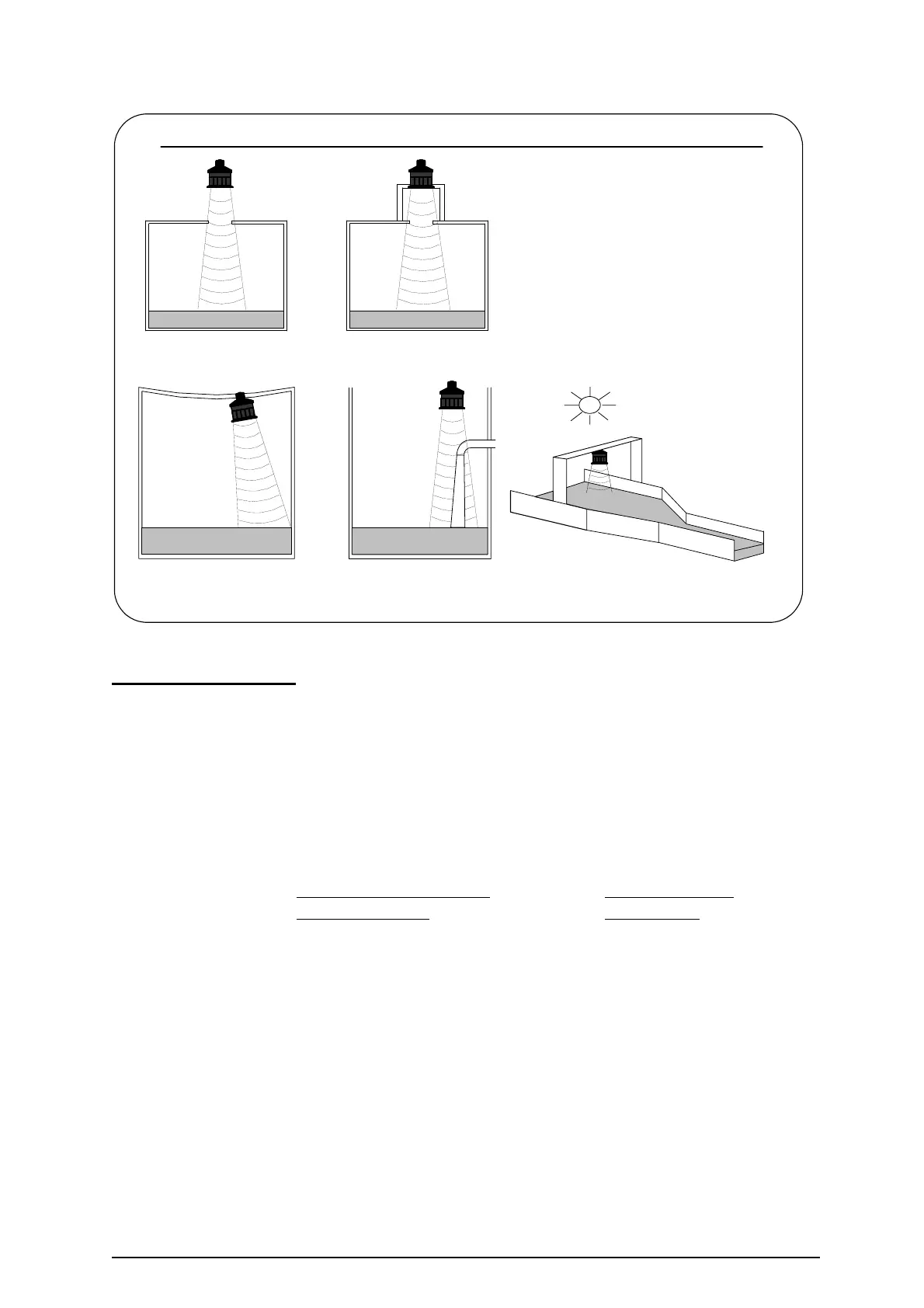

SECTION 1

KEEP TRANSDUCER

PERPENDICULAR

TO LIQUID.

KEEP TRANSDUCERS AND

TEMPERATURE COMPENSATION

PROBES OUT OF DIRECT

SUNLIGHT

DO NOT AIM THROUGH

HOLES IN THE TANK

AVOID ROUGH EDGES

IN STANDPIPES

AVOID INFLOWS OR

OTHER OBSTRUCTIONS

CAUTION: AVOID THE FOLLOWING TRANSDUCER INSTALLATION FAULTS

Figure 6: Transducer installation faults

Standpipe Installations

In many applications access to a vessel must be made via a standpipe. However, it is

necessary to observe some basic rules when fitting transducers into standpipes.

BLANKING: Parameter 4.0 should always be set at least 150mm longer than the

length of the standpipe.

STANDPIPE should be in accordance with the following table

DIMENSIONS:

Flange size and minimum

Maximum length

bore of Standpipe

of Standpipe

3" ( 80mm) 300mm

4" (100mm) 300mm

e.g. Using a 4" flanged transducer would require the standpipe length to be no more than

300mm and Pr.4.0 set at 450mm minimum.

The inside of the pipe and joint with vessel top must be clean and free of any

obstructions, seams or welds.

Ref: MINIFLEX LR MANUAL Rev. 0 7

Loading...

Loading...