SECTION 1

Transducer Mounting

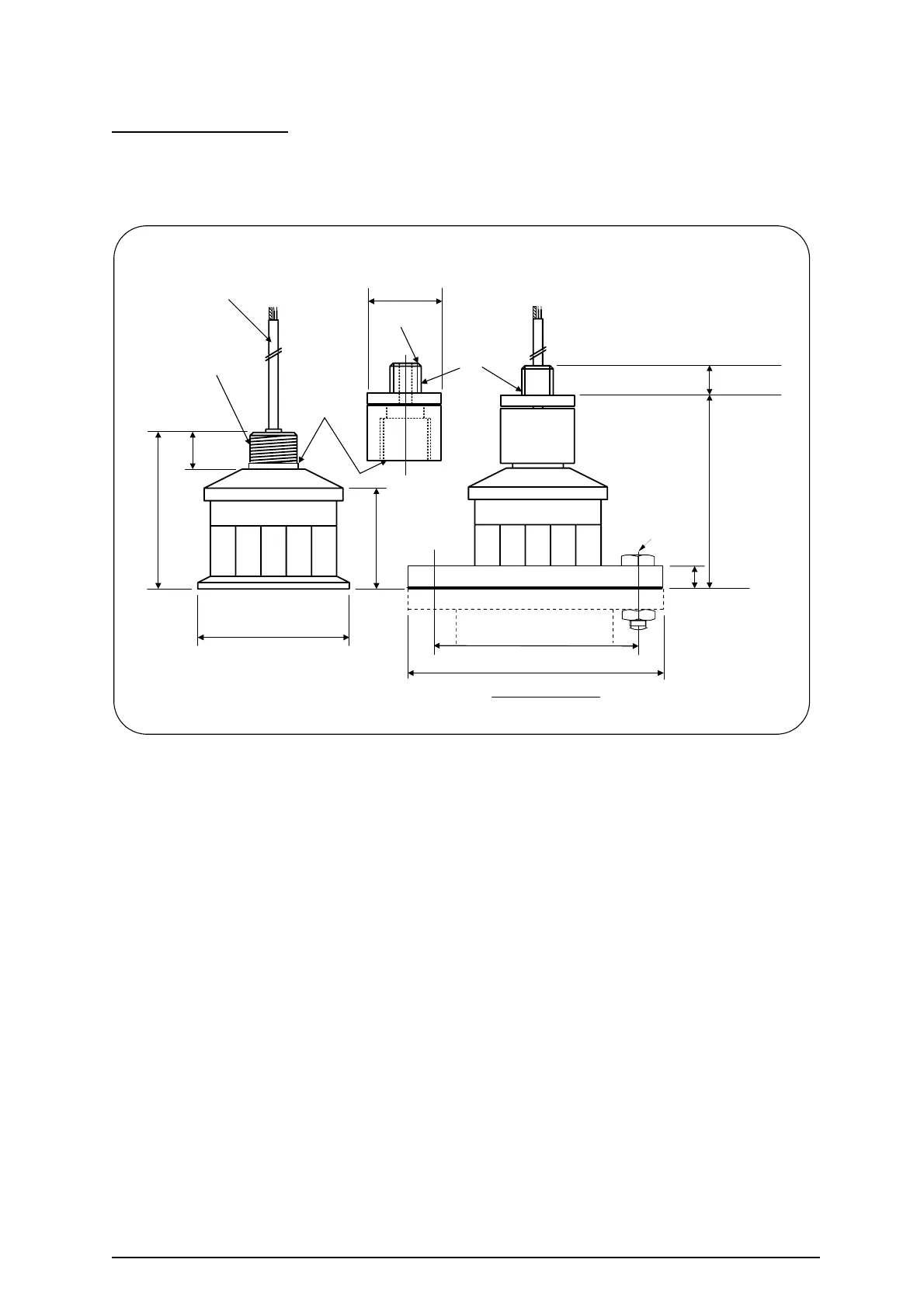

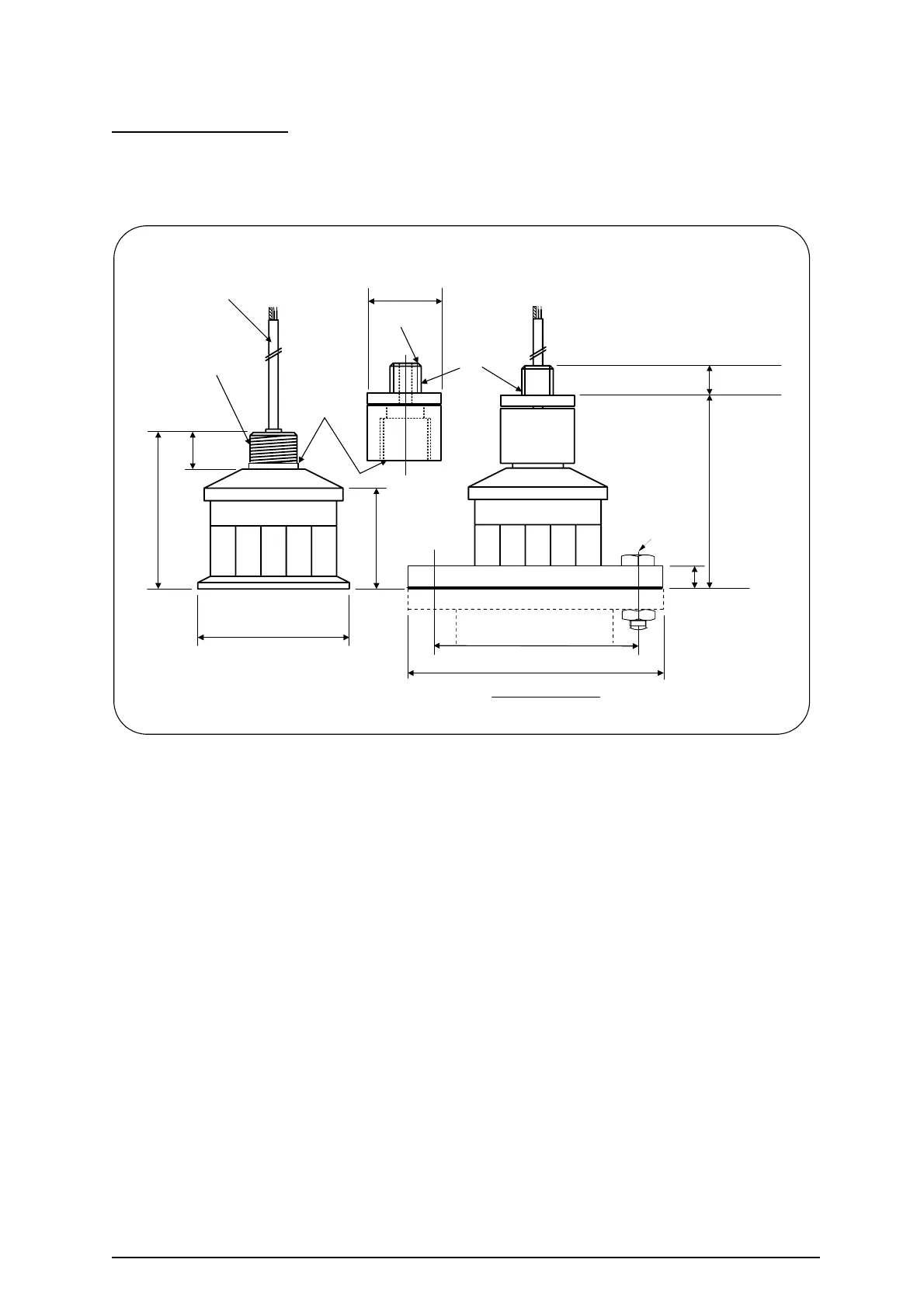

The transducer can be supplied as 'standard' or mounted in a flange. For applications

requiring chemical compatibility the transducer is available fully enclosed in PVDF in a

standard mounting or with flange. Figure 4 shows the dimensions:

Figure 4: Transducer mounting diagram

An isolation kit is provided with each transducer to minimise any ringing transmitted through

the mounting structure.

The transducer must be mounted perpendicular to the monitored surface and, ideally, at least

0.5 metres above it.

The transducer has a 12° inclusive conical beam angle at -3dB and must be mounted with a

clear unobstructed sight of the liquid to be measured over the complete measurement range.

The transducer is provided with integral cable which can be extended up to 300 metres using

a suitable junction box and RG62AU cable. The temperature compensated transducer

requires an additional single core screen extension, or twin-ax cable.

Refer to Page 8 for full details.

Transducer cables and temperature compensation cables can be run together but

should be separated from power cables by at least 150mm and preferably installed in

their own earthed steel conduit.

Isolation Kit

Fit as shown

102

M20 x 1.5

50 dia

M32 x 1.5

62

26

92 dia

10m cable 6.0 dia

20

130

assembled

height

20

Dia to suit flange selected

No. & size of bolts

to suit flange selected

Bolt hole PCD to suit

flange selected

INTEGRAL FLANGE

Ref: MINIFLEX LR MANUAL Rev. 0 5

Loading...

Loading...