16

5. WALL TIE TESTER KIT

KIT CONTENTS:

• 2000 model Medium Duty Tester with

xedGaugeto5kN*

• Wall Tie Spacer Bridge

• M5 & M6 Wall Tie Adaptors

•CalibrationCerticate

• Padded Carrying Case

* Some models have removable gauge and

coupler system

SITE TESTING OF

WALL TIES

The purpose of carrying out site tests on

wall ties is either as part of a site survey to

investigate the suitability of the base

material for the use of a particular tie or

during the installation of the ties to verify

the quality of the installation.

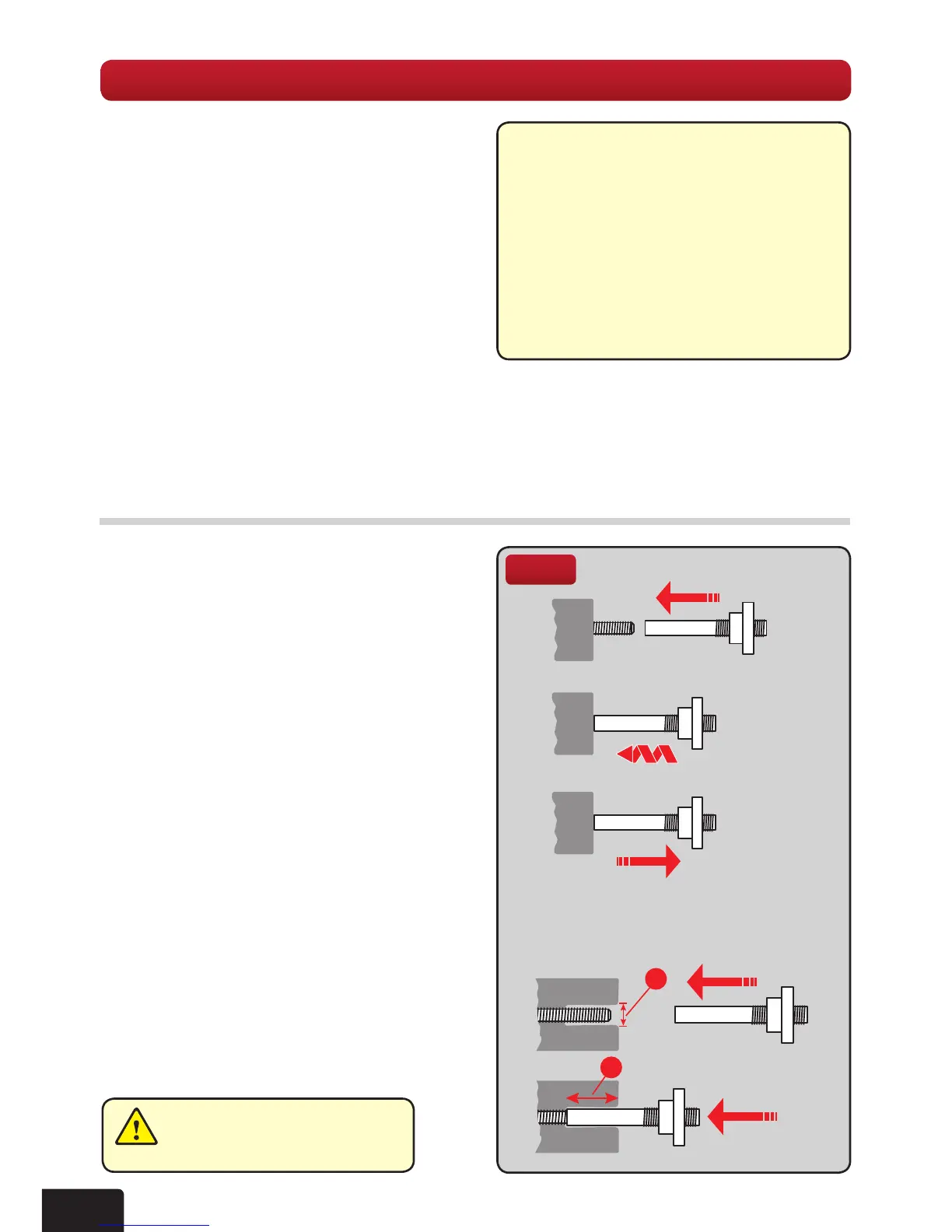

Fig 24

InaccordancewiththeBBArecommendationonRemedialwalltiesitisrequiredthat

therst3tiesinabuildingshouldbetestedfollowedby1tieinevery20installed.BRE

Digest401‘Replacingwallties’speciesthattheinnerendoftherst20tiesinstalledon

a contract should be all proof tested and that a reducing rate of testing is required for the

remaining ties, for 21 to 250 ties 10% should be tested, for 251 to 1000 ties 5% should be

tested and for more than 1000 ties 2.5% should be tested.

LOAD PROCEDURE

Generally the loading procedure for

testing wall ties is the same for both ends

of wall ties regardless of whether they are

mechanicalandchemicalxings,sothe

loading procedures which follow. Connect

the wall tie adaptor complete with the M12

threaded button adaptor to the end of the

wall tie, taking care not to tighten the outer

leaf expansion nut (g 24).

With the test meter securely attached to

the Bridge, adjusting the length of the legs

on the loading bridge and the position of

the button adaptor if necessary, pass the

adaptors through the keyhole slot in

the loading bridge and ensure that the

button adaptor is centred in the test

meter (g 25).

Use the levelling screws on the bridge

to take up the slack in the system and to

ensure that the test meter is axially

aligned with the wall tie under test.

DO NOT LOAD THE

TIE WITH THE

LEVELLING SCREWS.

Loading...

Loading...