9

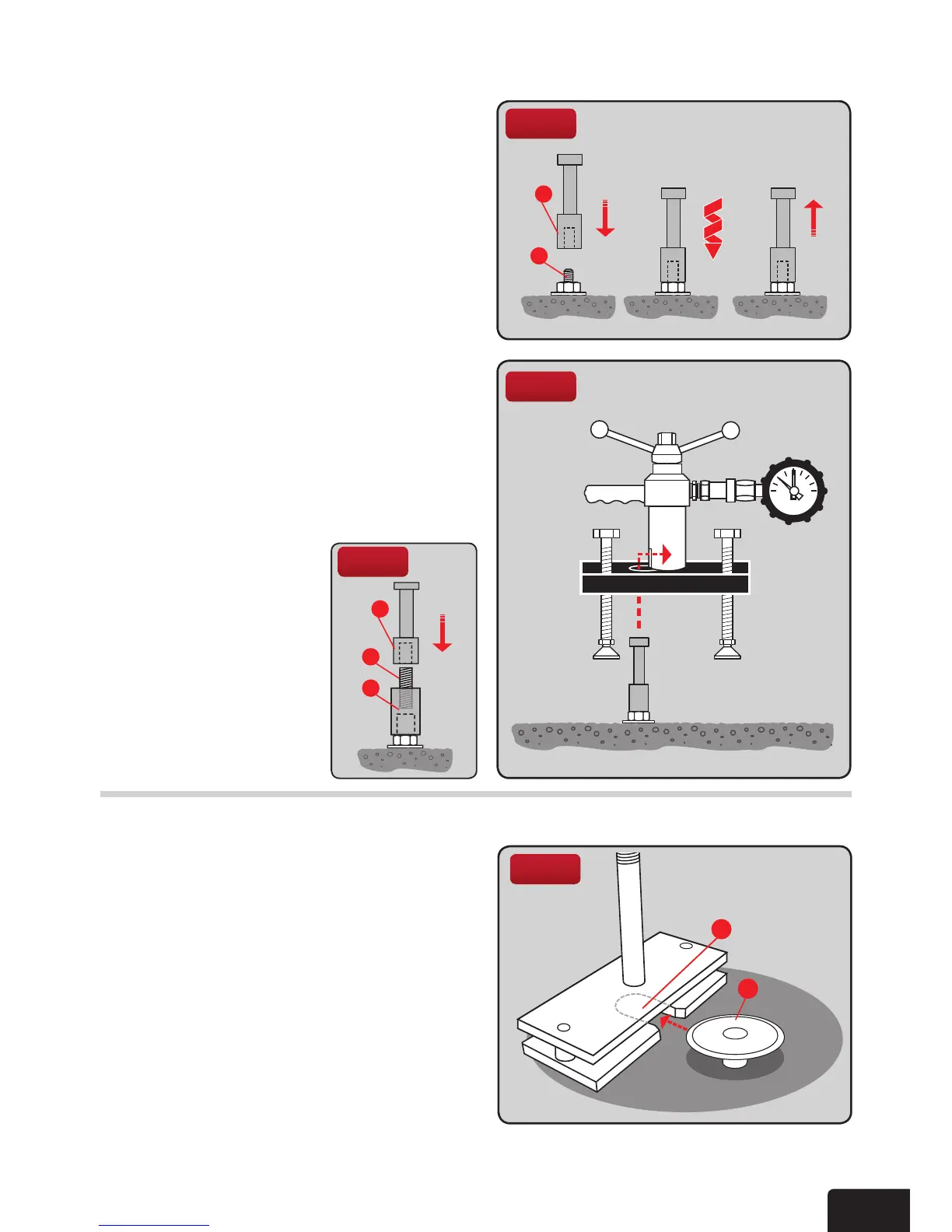

Remove the insulation around the fastener.

Mount the locking adaptor into the tester (see

Section 1 General testing procedure). Thread

the insulation adaptor into the locking adaptor

fully then back off until horizontal.

By holding the tester, slide the head of the

insulation fastener (a) between the two plates

withthestemofthexingrestingintheslotin

the lower plate (b) and adjust the legs on the

load spreading bridge to suit the base material.

Ensure that the pull-out force acts along the

axisofthexingbeingtested(g 15).

Hexagonal leg extensions may be required to

reach an insulation fastener that is raised.

2.3 THE INSULATION ADAPTOR

2.2 M10, M12, M16 AND M20 THREADED STUD ADAPTORS

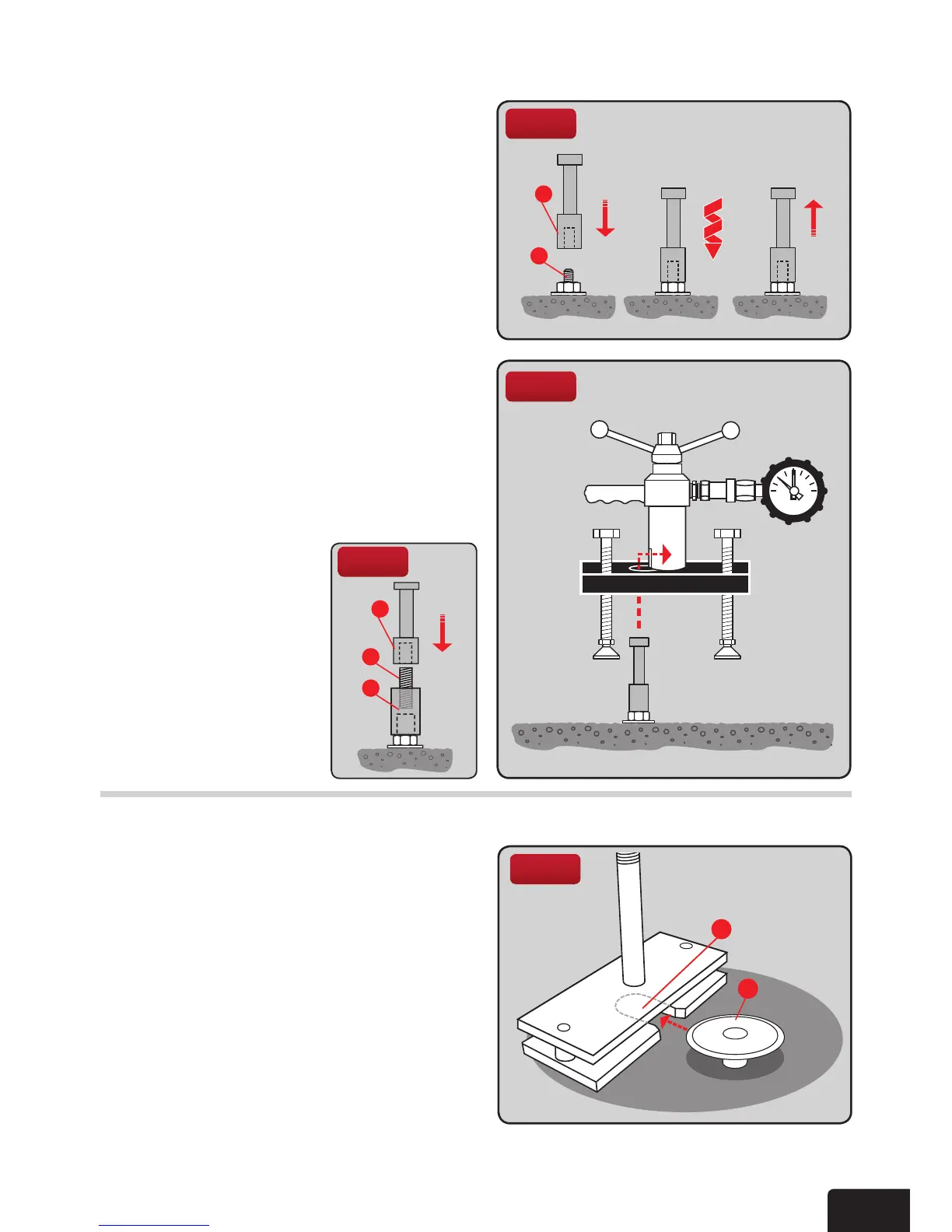

Fig 12

Suitable for testing sleeve and stud anchors.

(g 12) After the anchor has been set

in accordance with the manufacturers

recommendations, a suitable threaded

rod (a) is screwed into the anchor and the

adaptor (b)thentted.Thelengthofthe

threaded rod to be screwed into the anchor

must be at least equal to the diameter of the

anchor.

Removethelockingadaptoriftted(see

Section 1 General testing procedure).When

theadaptorissecurelyttedtotheanchor

thread position, place the tester over the

adaptor, passing the head through the hole

in the bridge and engage it in the pulling

jaw of the tester (g 13). Level the load

spreading bridge with the adjustable legs

before commencing the application of

the load.

Fig 13

b

a

1 2 3

Fig 15

b

a

Note: (g 14) To use

the optional M30 HD

Threaded stud adaptor,

rstattach45mmM20

thread piece (c) into

adaptor (e) and attach to

thexing.Thenthread

the M20 Adaptor (d)

and proceed as above.

Hexagonal leg extensions

may be required.

d

c

e

Fig 14

Loading...

Loading...