18

6. MATERIAL BOND TESTER KIT

Procedure for preparing samples for pull-off testing:

1. Clean the steel dollies (degrease and grit blast unless

otherwise stated). This will help to prevent interfacial

failures at the dolly interface.

2. For concrete substrates drill through the repair system

with diamond core drill at (90±)º to the surface into the

test surface by ~5mm or more.

This ensures a consistent bond area and will therefore

help reduce variations in the test results.

3. Clean the substrate test surface as recommended by

the manufacturer.

4. Mix the adhesive as recommended by the adhesive

supplier and add 1% by weight of ballotini (usually

0.5mm unless stated otherwise).

Adding ballotini will reduce alignment errors and

therefore help reduce variations in the test results.

5. Apply adhesive to steel dolly.

• 2000 model Medium Duty Tester with

xedGaugeto25kN*

• Bond test stool with adjustable legs

• 10x50mm & 10x 75mm steel bond

discs

• Bond test plug

•CalibrationCerticate

• Padded Carrying Case

(Can accommodate 20x50 & 20x75 discs)

ON SITE PULL

-

OFF METHOD

Equipment that may be required in

addition to the standard kit contents:

• Adhesive • Spatula

• Bondline spacers -

i.e.ballotini (glass spheres)

• Diamond-coated core drill

The bonding strengths of a wide and

varied range of materials including

concrete, screeds, repair mortars, epoxy

resin coatings, laminates, plastics,

paints and enamels may be accurately

determined using the Hydrajaws Material

Bond Tester.

Adequate direct tensile strength or

bonding strength between two layers is

important if repairs to concrete structures

or additional overlays and screeding on

existing concrete is to be structurally

sound.

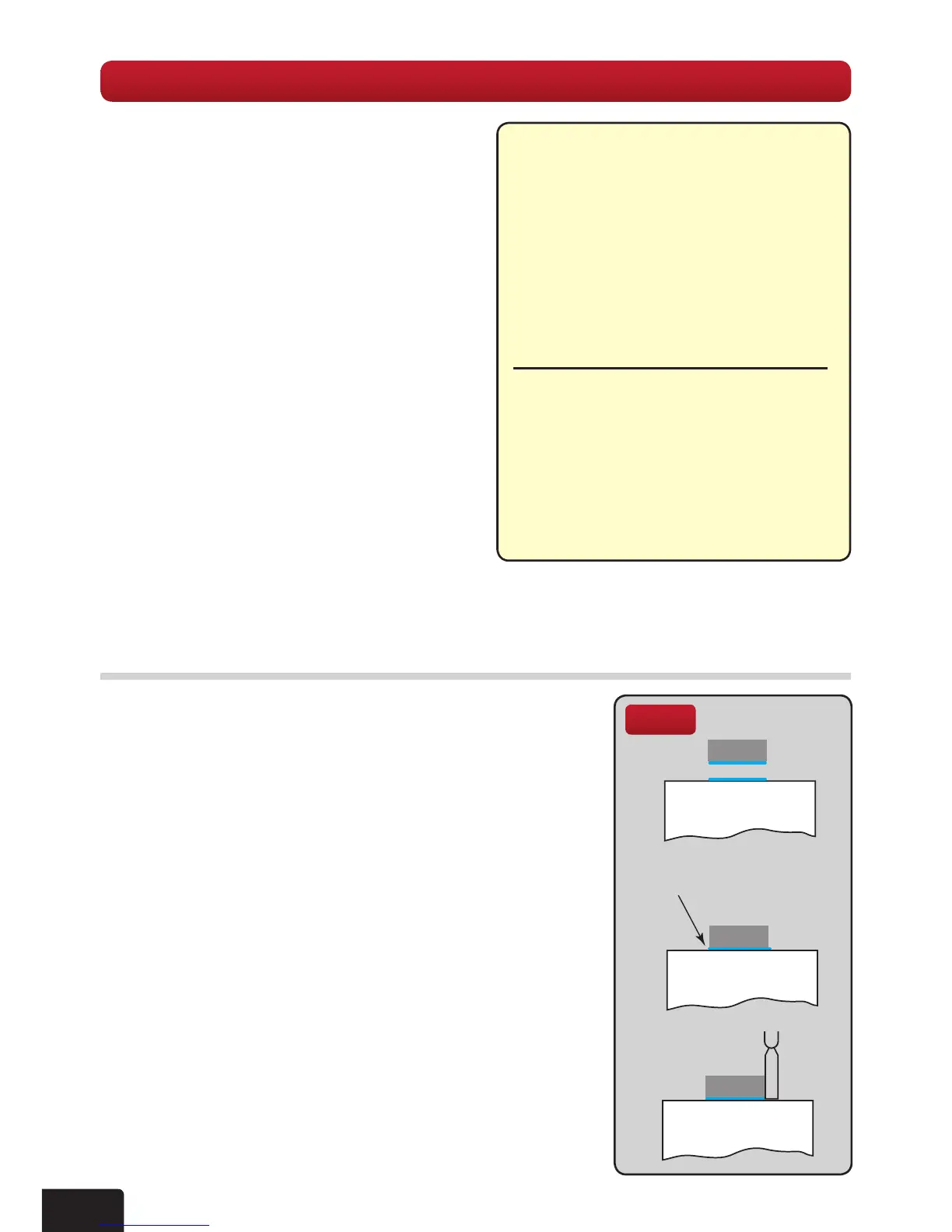

The pull-off test as a means of projecting

the compressive strength of concrete

and other materials involves bonding

a circular steel disc to the surface by

means of an epoxy resin adhesive.

KIT CONTENTS:

A controlled tensile force is then applied to the disc, and as the strength of the bond is

greater than that of the material under stress it will eventually fail in tension. From the

area of the disc and the force applied at failure it is possible to calculate a nominal tensile

strength for the material.

DOLLY

TEST SURFACE

Loading...

Loading...