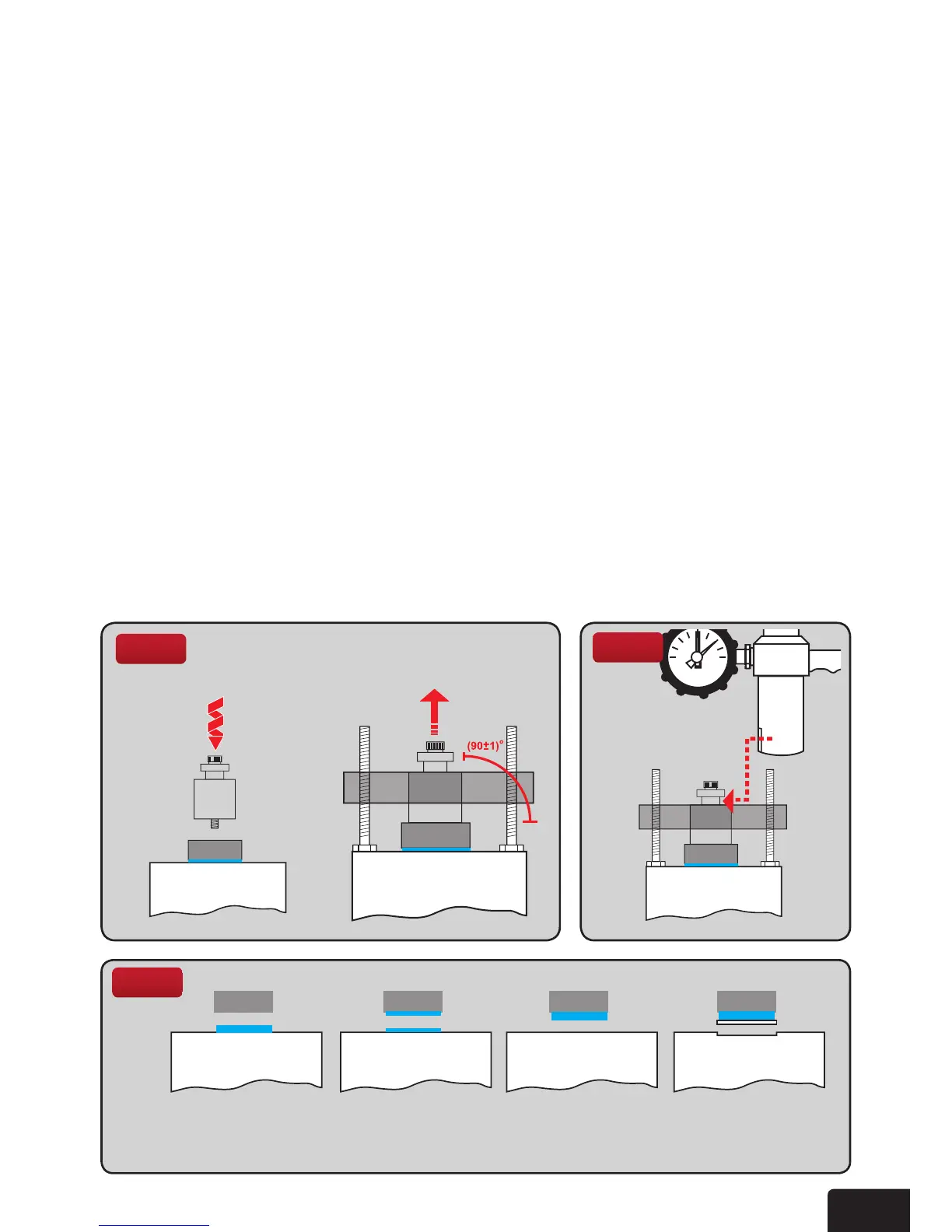

Fig 29

Interfacialfailure

to dolly.

Cohesive failure of

the adhesive.

Interfacialfailure

to substrate.

Substrate failure.

6. Apply adhesive to substrate test surface (g 26a). This ensures the adhesive wets out

both surfaces and helps prevent interfacial failures.

7. Pressthesteeldollyintothesubstratetestsurfacewitharmpressure(g 26b)

DONOT‘seat’thedollybytwistingitintoposition.Ifthedollyistwistedintopositionit

will increase the likelihood of interfacial failures.

8. Remove excess adhesive from around the edge of the dolly without disturbing its

position (g 26c). This ensures a consistent bond area and will therefore help reduce

variationsinthetestresults.Ifworkingonaverticaloroverheadsurface,ensurethe

dolliesareheldrmlyinpositionuntiltheadhesivehascured.

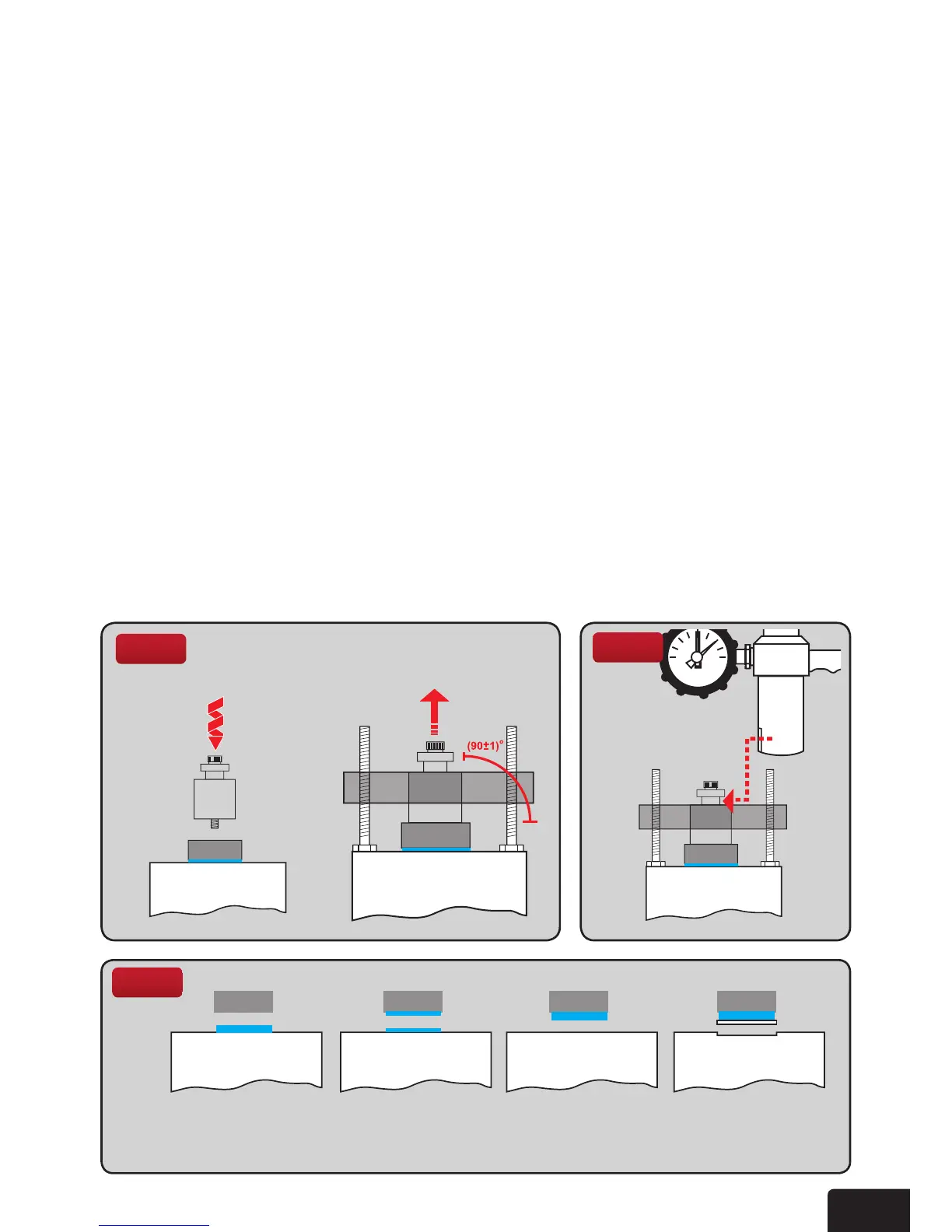

9. Connect centering plug to disc using the 8mm thread and hand tighten until bottom is

ushwithtopdisc(g 27a).

10. Lower load stool centre hole over centering plug and adjust the 3 screws until top of

plugisushandlevelwithtopofstool.Itisessentialthatthislevellingiscarriedout

carefully to ensure a square and smooth pull through the stool. The load applied to the

centre of the dolly should be at an angle of 90º±1 (g 27b).

11.SlideTesteroveradaptorontopofplugandt22mmsocketandratchettothe

operating nut (g 28). Secure equipment so that it does not move during testing.

This will cause excess misalignment which will reduce pull-off strengths.

12. Operate ratchet in a clockwise direction until required loading is obtained or bonding

breaks. Record test temperature, failure load and failure mode (g 29) (Record mixed

failure modes in percentages of bond area, i.e. 90% substrate failure, 10% cohesive

failure). Maximum loading achieved will be shown by red indicator pointer. Use this

reading to calculate the bond strength Mpa from the chart on page 20.

a

b

TEST SURFACE

Loading...

Loading...