O

PERATION

4-5

Operator Manual

Cutting

• Do not fire the pilot arc into the air needlessly—doing so causes a significant reduction of the

nozzle and electrode life.

• If arc transfer to the workpiece does not occur within 5 seconds, the pilot arc will shut off. Re-

lease the torch start switch and press it again to reset the pilot arc timer.

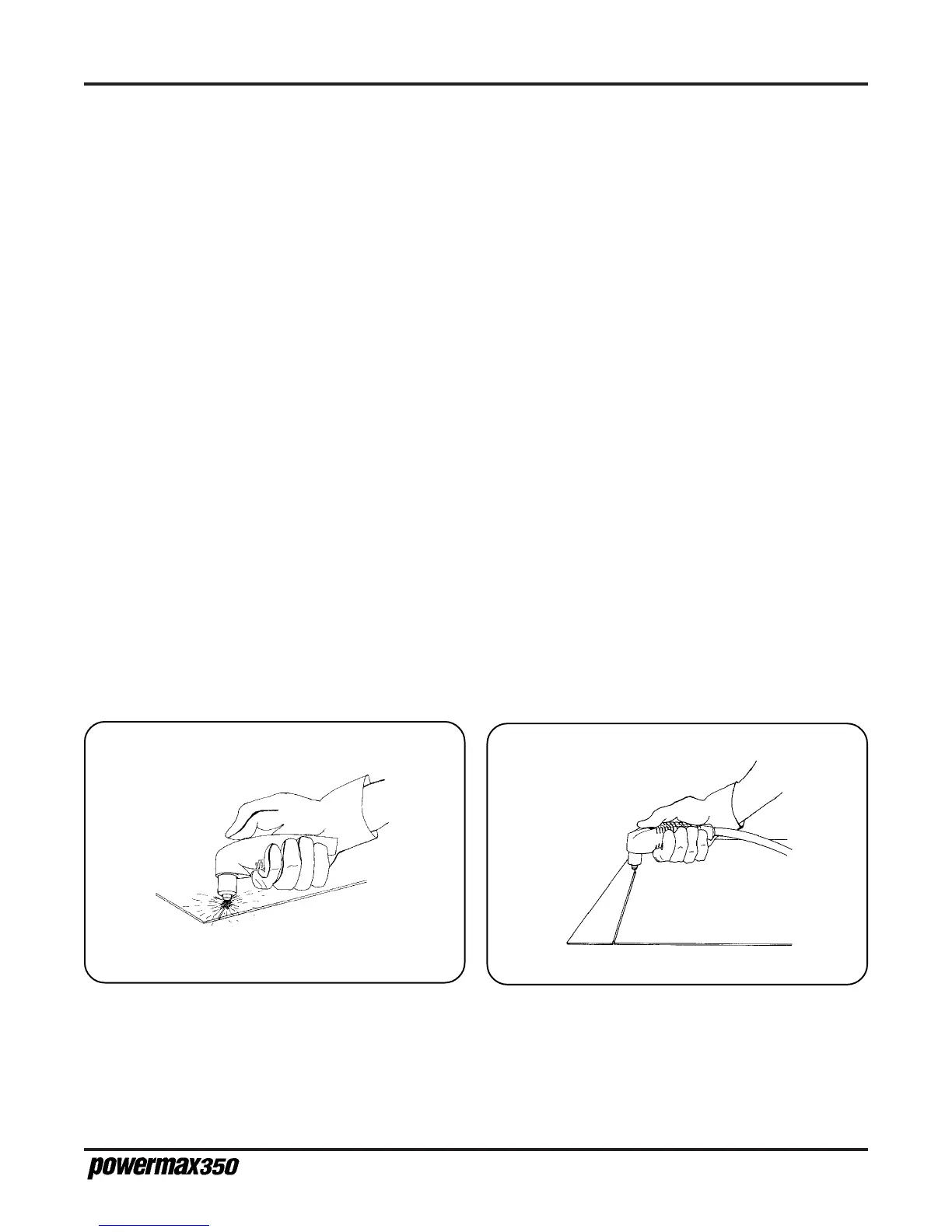

• Start cutting from the edge of the workpiece (Fig. 4-4).

• When cutting, make sure that the sparks are coming out of the bottom of the workpiece. If they

are spraying on top of the workpiece, you are moving the torch too fast, or you do not have

sufficient power to fully penetrate the workpiece.

• Hold the torch lightly on the metal or just above the metal. Holding the torch firmly to the work-

piece causes the shield or nozzle to stick and makes smooth cutting difficult. The arc transfers

to the workpiece once the torch is within 1/8 inch (3 mm) of the workpiece.

• Pulling the torch through the cut is easier than pushing it.

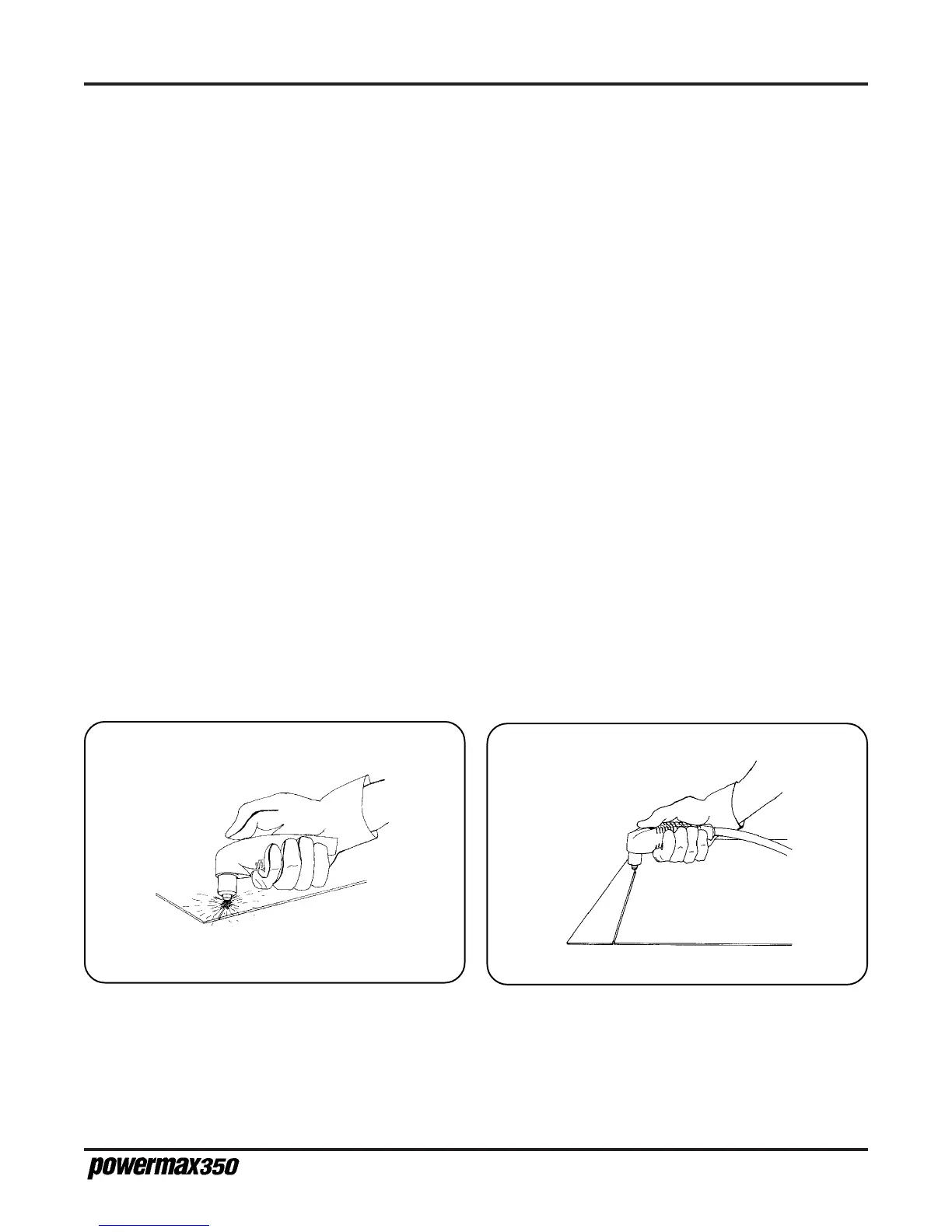

• Hold the torch nozzle at a vertical position and watch the arc as it cuts along the line (Fig. 4-5).

By lightly dragging the nozzle on the workpiece, you can maintain a steady cut. For straight-line

cuts, use any straight edge as a guide.

• When cutting thin material, reduce the amps until you get the best quality cut.

• To cut circles, use a template or a radius cutter attachment (Fig. 4-6).

Figure 4-4 Starting a Cut Figure 4-5 Dragging the Torch

8-97

Loading...

Loading...