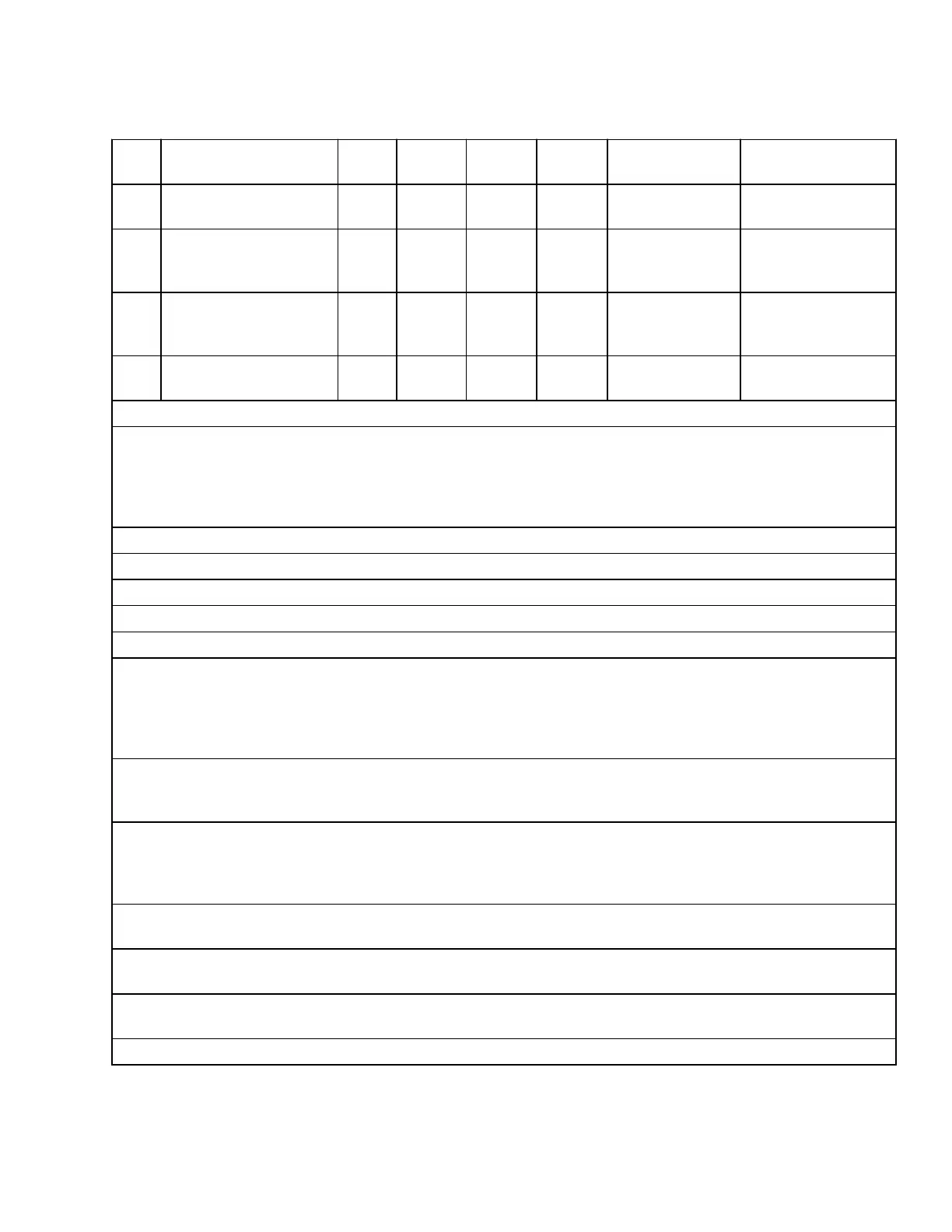

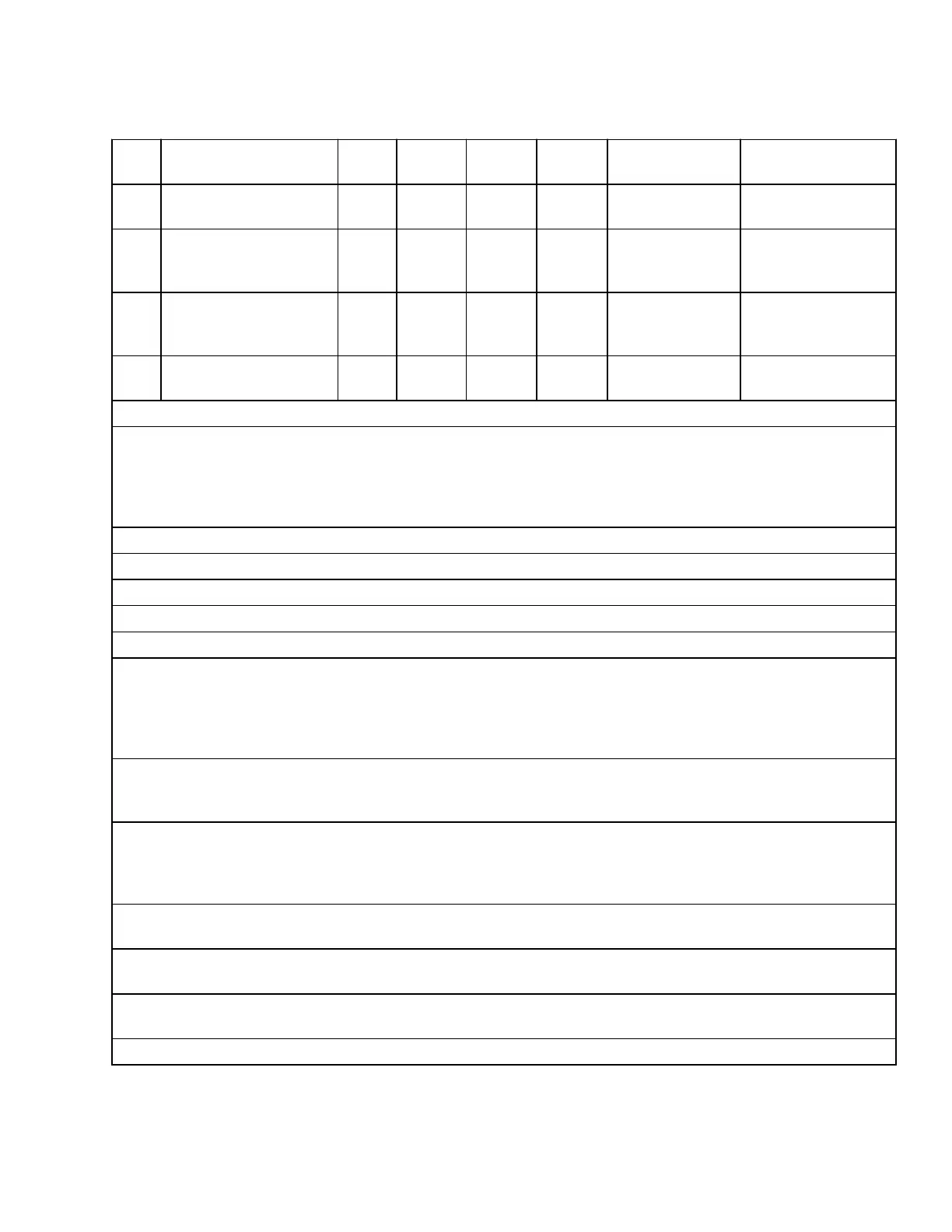

Table 1. Maintenance Schedule (Continued)

Item

No.

Item 8 hr/

Daily

500 hr/

3 mo

2000 hr/

1 yr

4000 hr/

2 yr

Procedure or

Quantity

Specification

Automatic Parking

Brake Cable Barrel

L

Automatic Parking

Brake Cable

X Check condition.

Replace as

necessary.

See NOTE 7.

Automatic Parking

Brake Actuator and

Levers

Replace actuator

and levers.

See NOTE 7.

Mast and Carriage

with Paper Roll Clamp

X Inspect.

NOTE 10

Dye Penetrant.

NOTE 1: Multipurpose grease with 2 to 4% Molybdenum Disulfide.

NOTE 2: Recommended service intervals are based on a normal application in a clean environment.

Applications involving contaminated environments such as high levels of air borne debris (dust and waste

paper); chemical or abrasive compounds; poor ground conditions; intensive usage at high performance

levels; or other abnormal conditions will require more frequent servicing. At your request your dealer will

advise you of the appropriate service intervals based on an application survey.

NOTE 3: Lubricate if dry or at first sign of visible surface rust

NOTE 4: Equalization charge is required approximately each month.

NOTE 5: Maximize life of surface by lubricating every 250 hours for first 1000 hours.

NOTE 6: Multipurpose lithium base grease.

NOTE 7: Replace at 10,000 hours. See Transaxle 1300SRM1539 for procedures.

NOTE 8: Hydraulic oil sampling and analysis is a recommended practice. See Hydraulic Cleanliness

Procedures 1900SRM1620 for oil cleanliness and water content guidelines. For lift trucks operating in

heavy duty applications or highly contaminated environments, take oil samples every 500 hours. Normal

Operating conditions may allow for less frequent oil sampling. Oil sampling should be done just prior to all

oil and filter changes.

NOTE 9: Vehicles used in paper application require regular inspection and cleaning to minimize risk of fire.

This should be done at least once every 8 hours or more frequently depending upon operating environment.

Use compressed air and steam clean as necessary.

NOTE 10: Inspect after an impact likely to cause damage. In large diameter paper-roll production

applications, inspect at first 4000 hours with subsequenct inspection at 2000-hour intervals. At your

request your Hyster dealer will advise you of the appropriate service intervals based on an application

survey.

NOTE 11: Lubricate with anti-seize grease compound for lift trucks equipped with Outdoor Protection/

Wash-down Package.

NOTE 12: Spray electrical connections with rust inhibitor-ignition sealer, after components are properly

tightened, for lift trucks equipped with Outdoor Protection/Wash-down Package.

NOTE 13: Coat all brake linkage pivot points, exposed brake cables, pivot shafts, and bushings with anti-

seize lubricant for lift trucks equipped with Outdoor Protection/Wash-down Package.

X=Check C=Change L=Lubricate CIL=Check Indicator Light during operation

8000 SRM 1541 Maintenance Schedule

11

Loading...

Loading...