Inspection of Mast, Carriage, Header Hoses,

Lift Chains, and Attachments

WARNING

Lower the lift mechanism completely. Never allow

any person under a raised carriage. DO NOT put

any part of your body in or through the lift mecha-

nism unless all parts of the mast are completely

lowered and the lift truck traction motor is OFF.

1.

Inspect the welds on the mast, cylinders, and

carriage for cracks. Make sure that the cap-

screws and nuts are tight.

2.

Inspect the channels for wear in the areas

where the rollers travel. Inspect the rollers for

wear or damage.

3.

Inspect the load backrest extension for cracks

and damage.

4.

If the lift truck is equipped with a sideshift car-

riage or attachment, inspect the parts for

cracks and wear. Make sure the parts that fas-

ten the sideshift carriage or attachment to the

carriage are in good condition.

WARNING

Always wear the proper protective equipment in-

cluding eye protection and petroleum-resistant

gloves when handling hydraulic oil. Thoroughly

wash oil from exposed areas of skin as soon as

possible.

WARNING

Never check for leaks by putting hands on hy-

draulic lines or components under pressure. Hy-

draulic oil under pressure can be injected into the

skin.

5.

Visually inspect hoses/fittings for hydraulic

leaks; hose covers for cuts, cracks, or exposed

reinforcement; defective/broken clamping devi-

ces or sheaves; and proper tracking during op-

eration. Adjust/repair/replace hose/components

as necessary.

6.

Check that lift chains are correctly lubricated.

Use SAE 30W engine oil to lubricate lift chains.

7.

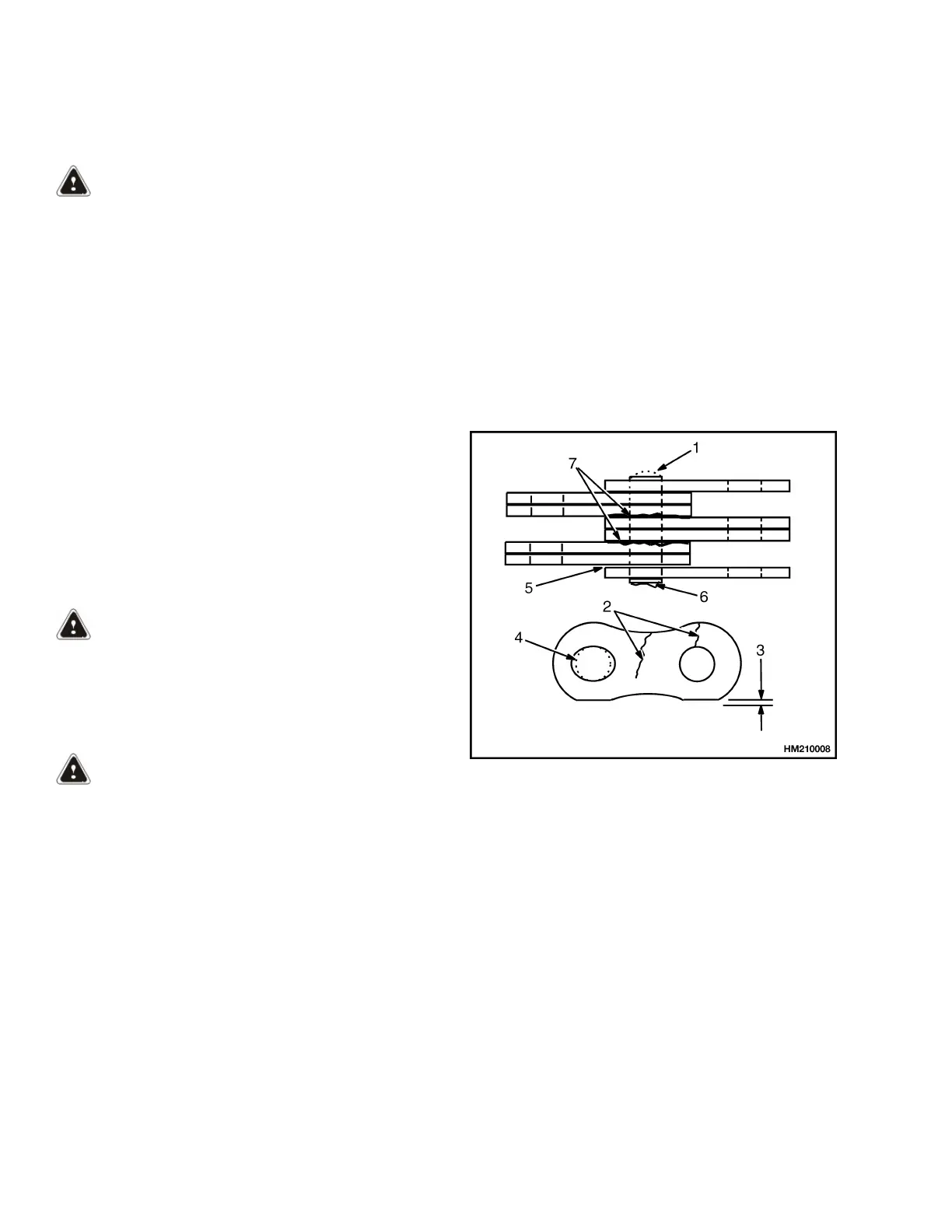

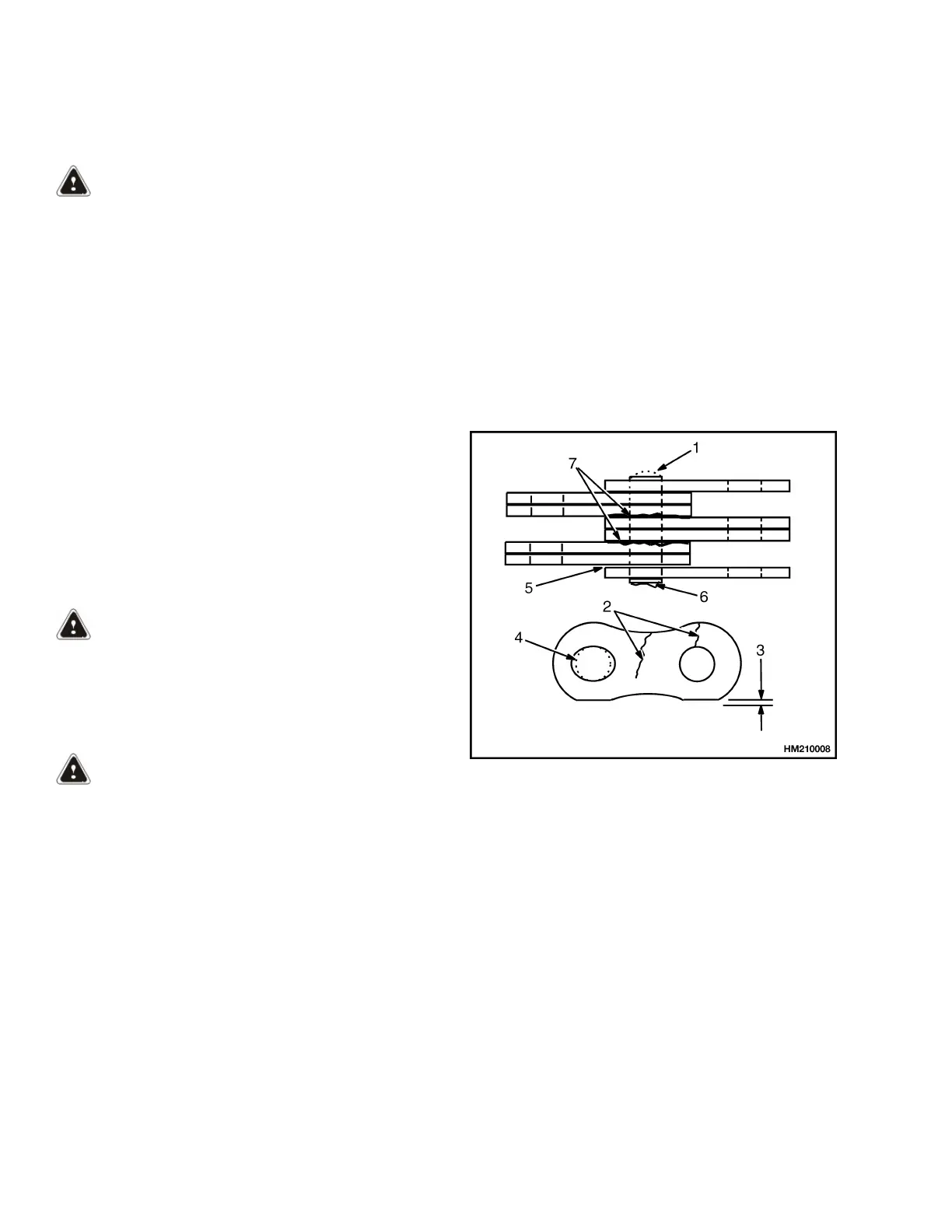

Inspect the lift chains for cracks or broken links

and worn or turned pins. Lift chains must be

replaced as a set. See Figure 8.

NOTE: Chain anchor pins MUST be replaced any-

time chains are replaced.

8.

Inspect the chain anchors and pins for cracks

and damage.

9.

Make sure the lift chains are adjusted so that

they have equal tension. Adjustments or re-

placement of the lift chains must be done

by authorized personnel.

1. WORN PIN

2. CRACKS

3. EDGE WEAR (MAXIMUM 5% OF NEW)

4. HOLE WEAR

5. LOOSE LEAVES

6. DAMAGED PIN

7. CORROSION

Figure 8. Lift Chains Check

Maintenance Procedures Every 8 Hours or Daily 8000 SRM 1541

14

Loading...

Loading...