Maintenance Procedures Every 8 Hours or Daily

WARNING

DO NOT operate a lift truck that needs repairs. Re-

port the need for repairs immediately. If repair is

necessary, put a DO NOT OPERATE tag in the op-

erator's area. Remove the key from the key switch

or cover the keyless switch.

Inspect the lift truck after every eight hours or

daily before use. Put the lift truck on a level sur-

face. Lower the carriage and forks and turn the key

or keyless switch to the OFF position. Apply the

Automatic Parking Brake (APB). Remove the floor

mat and floor plate and inspect for leaks and condi-

tions that are not normal. Clean any oil spills.

Make sure that lint, dust, paper and other materi-

als are removed from the compartments. Make the

additional checks as described in the following

paragraphs of How to Make Checks With Key or

Keyless Switch OFF and How to Make Checks

With Key or Keyless Switch ON.

HOW TO MAKE CHECKS WITH KEY OR

KEYLESS SWITCH OFF

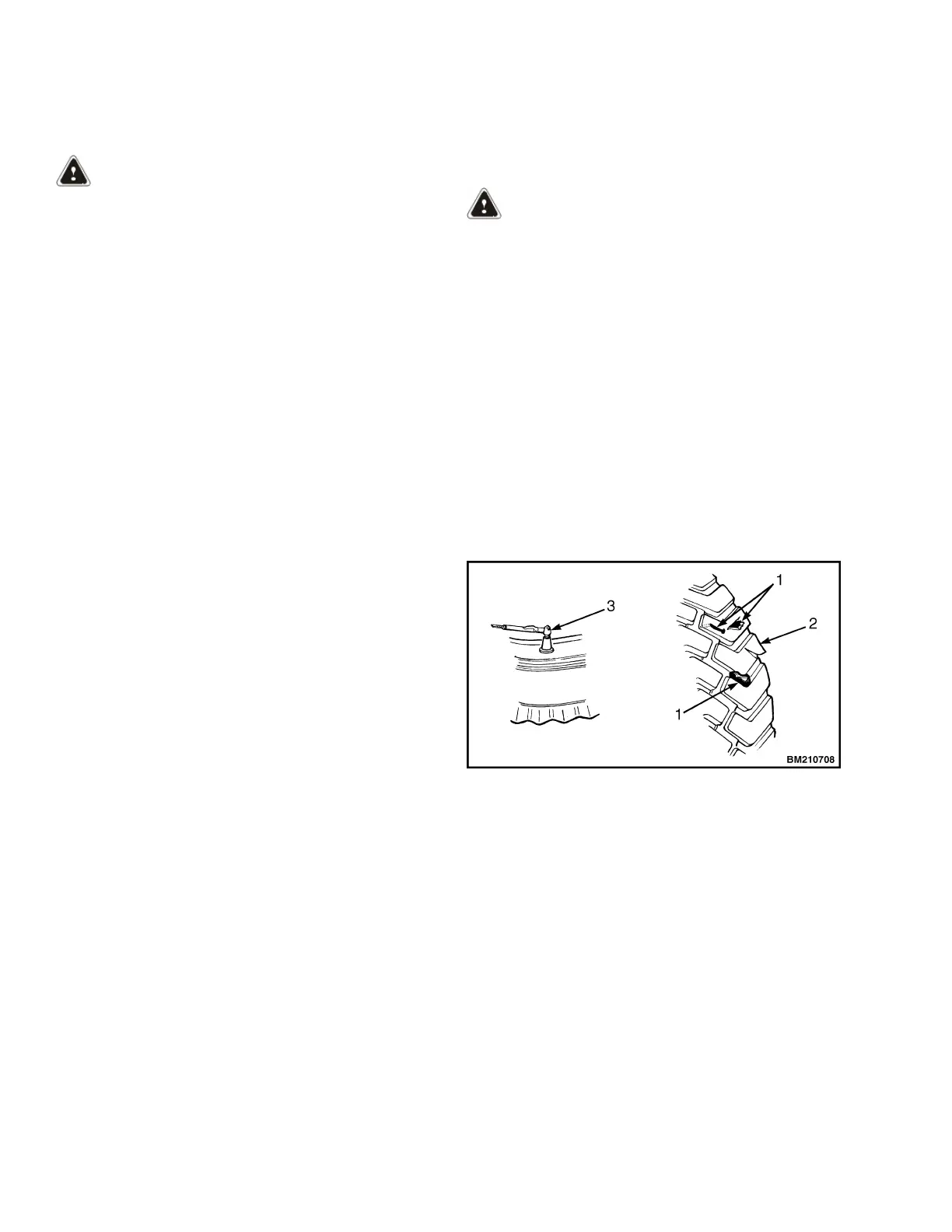

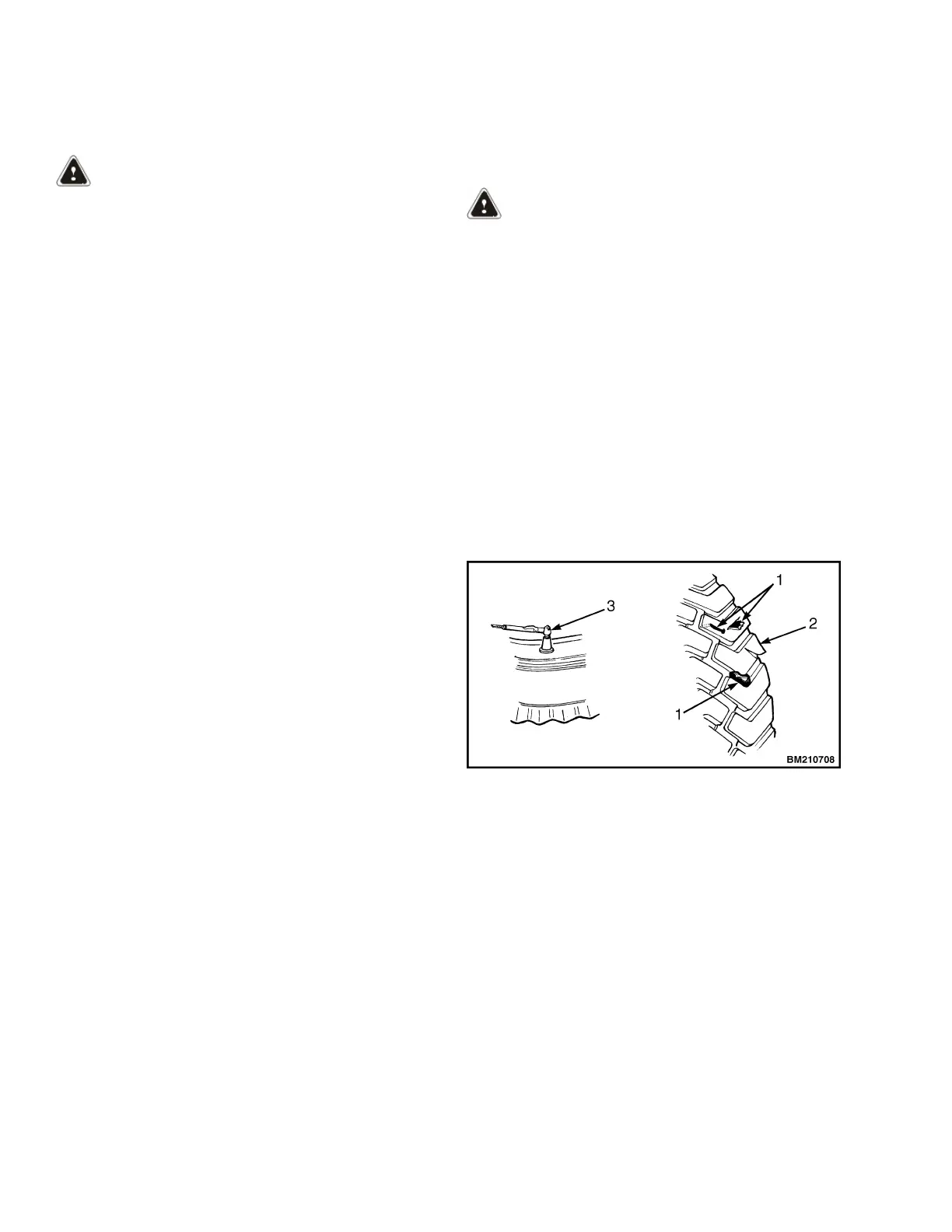

Tires and Wheels

Inspect the tires for wire, rocks, glass, pieces of

metal, holes, cuts and other damage. Remove any

object that will cause damage. Check for loose or

missing hardware. Remove any wire strapping or

other material that is wrapped around the axle. See

Figure 5.

Forks

General

NOTE: Forks must be removed and installed by

trained personnel.

The identification of a fork describes how the fork is

connected to the carriage. These lift trucks have

hook forks.

Inspect

WARNING

DO NOT try to correct fork tip alignment by bend-

ing the forks or adding shims. Replace bent forks.

Never repair damaged forks by heating or weld-

ing. Forks are made of special steel using special

procedures. Replace damaged forks. Forks are to

be replaced only in sets and not individually.

1.

Inspect the forks for cracks and wear. Check

that the fork tips are aligned as shown in Fig-

ure 6.

2.

Check that the bottom of the fork is not worn

(item 4 in Figure 6).

3.

Replace any damaged or broken parts that are

used to keep the forks locked in position. See

Figure 7.

1. CHECK FOR DAMAGE AND REMOVE NAILS,

GLASS, METAL, AND OTHER OBJECTS FROM

TREAD

2. CHECK EDGES FOR WEAR

3. CHECK TIRE PRESSURE

Figure 5. Tires Check

Maintenance Procedures Every 8 Hours or Daily 8000 SRM 1541

12

Loading...

Loading...