Seat Adjustment for Operator Weight

CAUTION

A major cause for high Whole Body Vibration is

caused by the operator not adjusting the seat to

his/her weight.

NOTE: It is important to adjust the weight setting

for each operator.

NOTE: The seat is designed for a maximum weight

of 135 kg (298 lb).

• The target is for the "ride indicator" to fall

between the arrows when the operator sits

upright on the seat with the feet positioned

on the pedals. This ensures that the operator

is set at the midpoint of the 80 mm (3.5 in.)

suspension. See Figure 11.

• The weight adjustment handle can be turned

as shown to increase or decrease the weight

resistance Pull handle out before turning. As

handle is turned the "stiffness" of the sus-

pension can be felt to increase or decrease

depending on which way the handle is

turned.

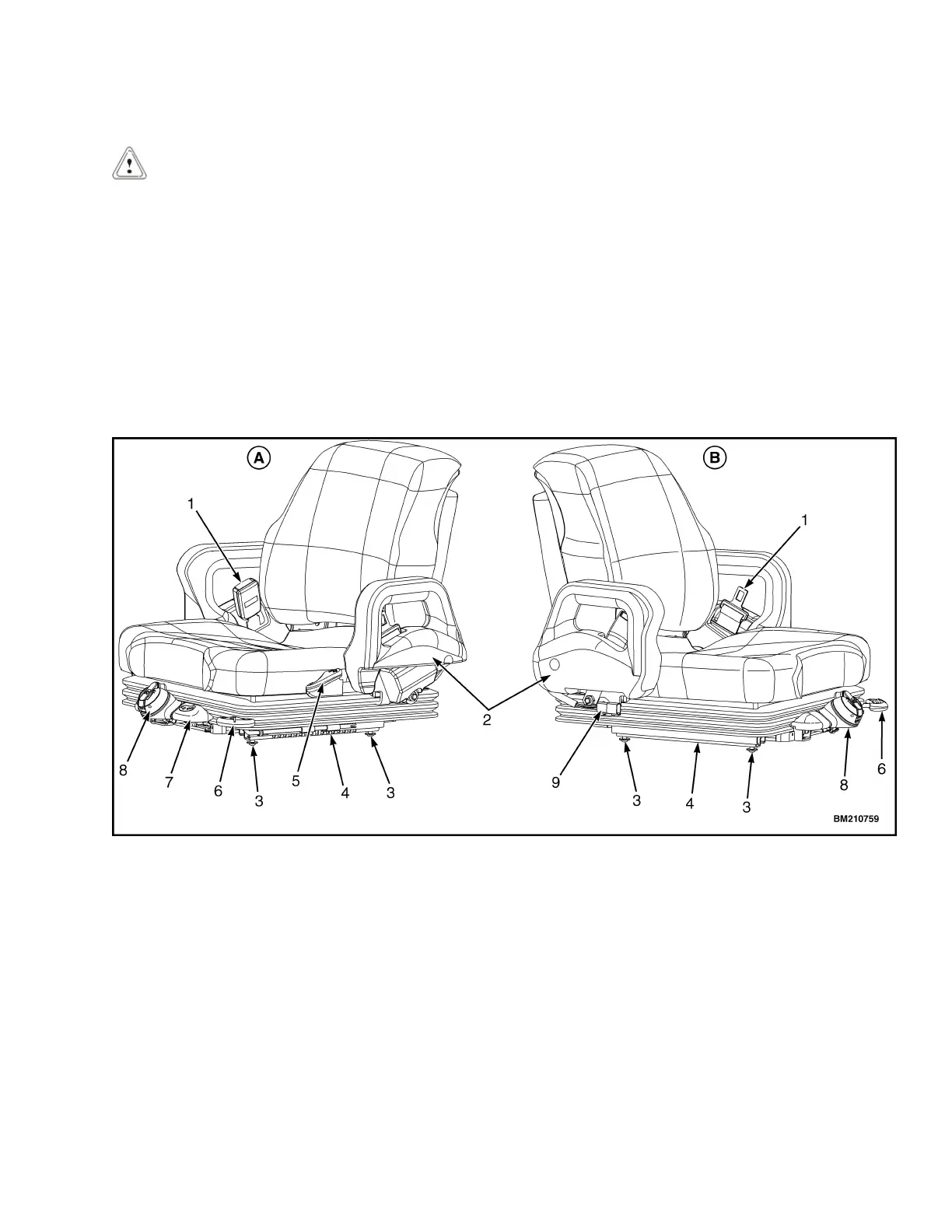

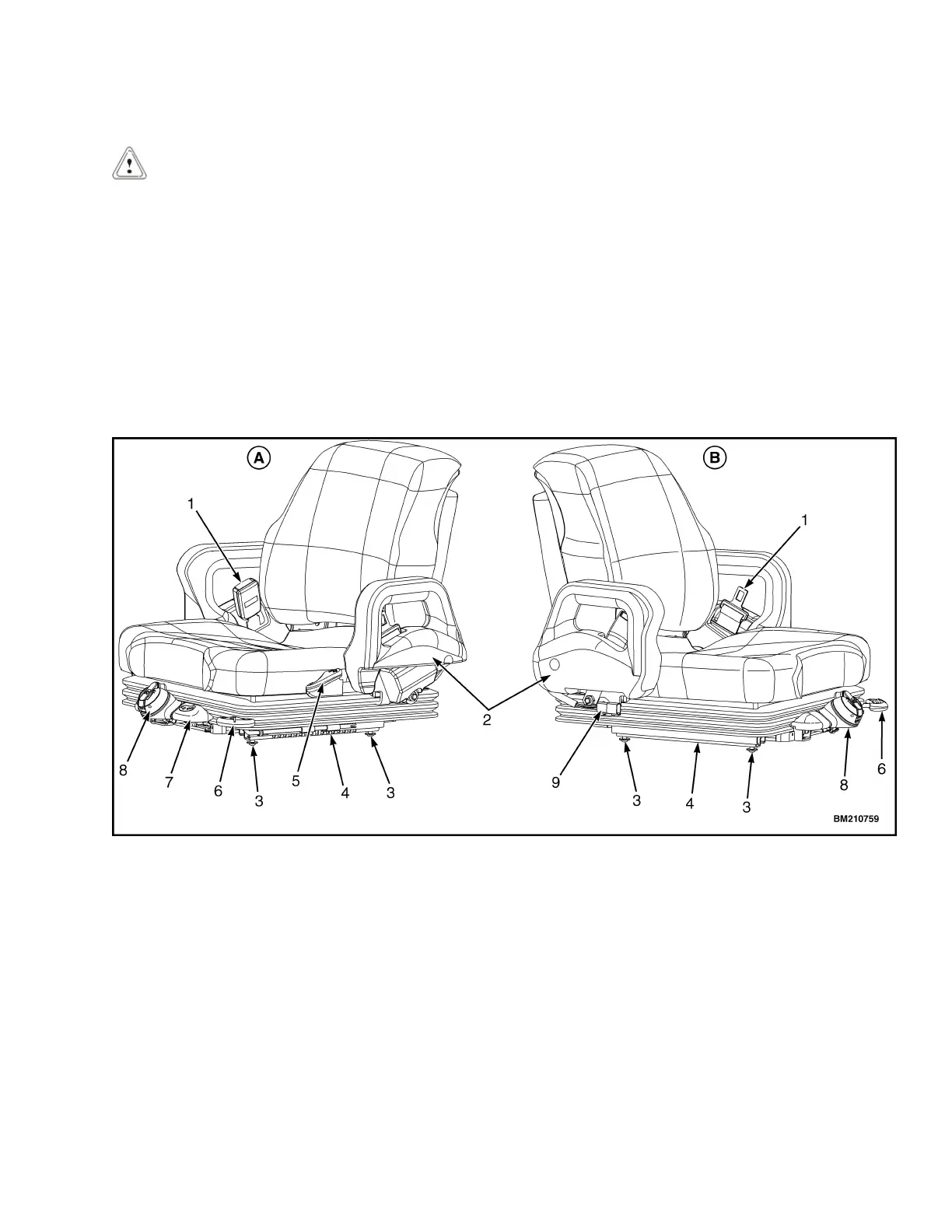

NOTE: STANDARD SEAT SHOWN. AN OPTIONAL SWIVEL SEAT IS AVAILABLE. SWIVEL SEAT ARRANGE-

MENT IS THE SAME. HIP RESTRAINTS FOR LIFT TRUCKS WITH MANUAL HYDRAULIC SYSTEM SHOWN.

A. LEFT VIEW B. RIGHT VIEW

1. SEAT BELT

2. HIP RESTRAINT BRACKET

3. MOUNTING HARDWARE

4. SEAT RAILS

5. BACKREST ANGLE ADJUSTMENT LEVER

6. FORWARD/BACKWARD ADJUSTMENT LEVER

7. RIDE POSITION INDICATOR

8. WEIGHT ADJUSTMENT KNOB

9. SEAT HARNESS

Figure 10. Seat Components and Operator Restraint System

8000 SRM 1541 Maintenance Procedures Every 8 Hours or Daily

17

Loading...

Loading...