Reference Surface

Reference Surface

Reference Surface

Reference Surface

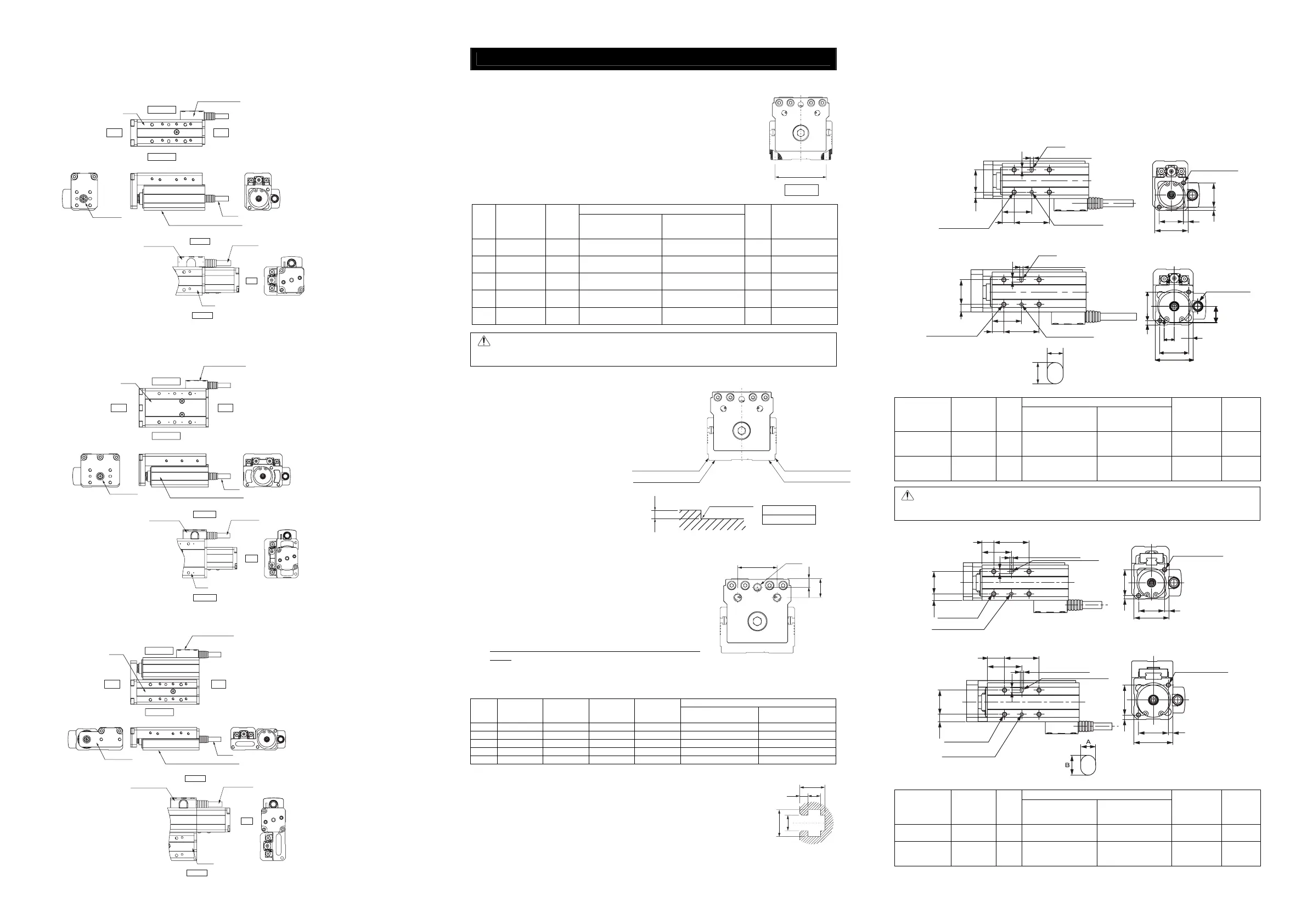

2. Total Length Short Type

2.1 Compact Type

RCA2-TCA3NA, TCA3N (Lead Screw, Ball Screw), TCA4NA, TCA4N (Lead Screw, Ball Screw)

• Without Brake

• Brake-equipped

2.2 Wide Type

RCA2-TWA3NA, TWA3N (Lead Screw, Ball Screw), TWA4NA, TWA4N (Lead Screw, Ball Screw)

• Without Brake

• Brake-equipped

2.3 Flat Type

RCA2-TFA3NA, TFA3N (Lead Screw, Ball Screw), TFA4NA, TFA4N (Lead Screw, Ball Screw)

• Without Brake

• Brake-equipped

Attachment

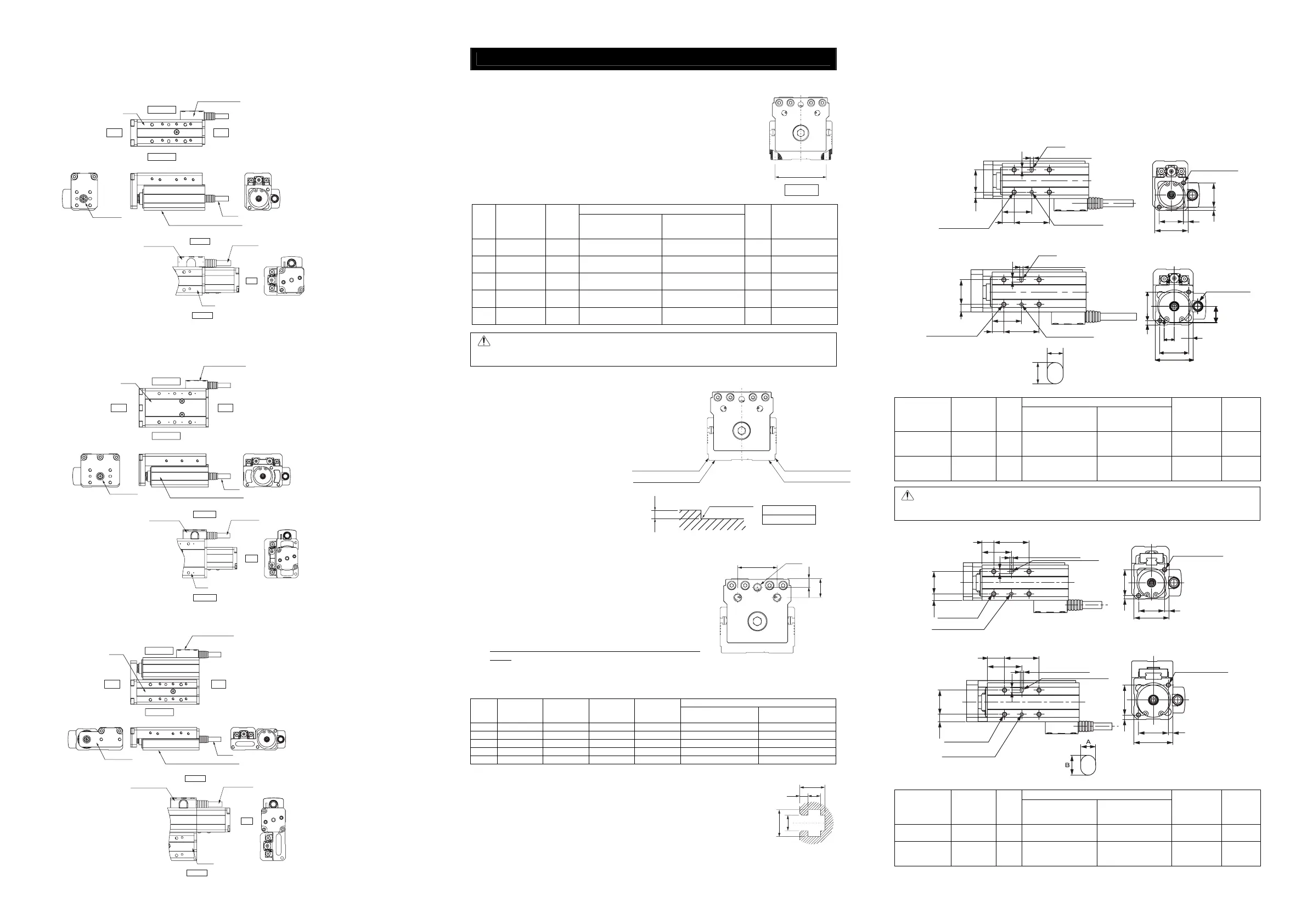

1. Motor Unit Type

RCP3-TA3C, TA4C, TA5C, TA6C, TA7C, TA3R, TA4R, TA5R, TA6R, TA7R

RCA2-TA4C, TA5C, TA6C, TA7C, TA4R, TA5R, TA6R, TA7R

1.1 Installing the Actuator

Fix it using the tapped hole on the rear side.

Description of the Set Screws

• For the base male set screw, use a hexagon socket head cap screw.

• For the bolt to be used, a high-tensile bolt complying with ISO-10.9 or more is

recommended.

• The length of thread engagement should be 1.8 times more than the nominal

diameter, and pay attention not to stick the screw out inside the actuator.

Tightening Torque

Model

Tap Size and

Max. Screw

Depth

Bolt to

be used

In the case that steel is

used for the bolt seating

surface:

In the case that aluminum

is used for the bolt seating

surface:

A(mm) Reamed Hole(mm)

TA3 M3 Depth 5 M3 1.54N·m(0.16kgf·m) 0.83N·m(0.085kgf·m) 28

Depth 3.5 from the

φ3H7 Base Surface

TA4 M4 Depth 7.5 M4 3.59N·m(0.37kgf·m) 1.76N·m(0.18kgf·m) 31

Depth 4.5 from the

φ4H7 Base Surface

TA5 M5 Depth 10 M5 7.27N·m(0.74kgf·m) 3.42N·m(0.35kgf·m) 45

Depth 5 from the

φ5H7 Base Surface

TA6 M5 Depth 10 M5 7.27N·m(0.74kgf·m) 3.42N·m(0.35kgf·m) 55

Depth 5 from the

φ5H7 Base Surface

TA7 M6 Depth 12 M6 12.34N·m(1.26kgf·m) 5.36N·m(0.55kgf·m) 64

Depth 6 from the

φ6H7 Base Surface

Note : Take care in selecting the bolt. Using a bolt with inappropriate length may cause damage to

the tapped hole, insufficient attachment strength of the actuator or interference with the

driving section, which may result in degradation of accuracy, damage or unexpected accident.

1.2 Attachment Surface

• The base has to have a structure with

sufficient rigidity to prevent oscillation.

• For the surface to which the actuator is

attached, a machined surface or flat one

with equivalent accuracy should be used.

The flatness should be within ±0.05mm/m.

• Secure the space where maintenance work

can be performed.

• This surface is used as the reference for the

actuator base side and lower side slider

running. In the case that the running

accuracy is required, attach the actuator

using this surface as the reference.

Refer to the following figure for the

processing when the actuator is attached to

the base using the base reference surface.

1.3 Attachment of the payload to be carried

• Fix the payload to be carried using the tapped hole on the front

plate or on the table upper surface.

• For the male set screw, use a hexagon socket head cap screw.

• For the bolt to be used, a high-tensile bolt complying with

ISO-10.9 or more is recommended.

• There are the two reamed holes on the upper surface of the table.

In the case that the reproducibility for the attachment and

removal is required, use these reamed holes. Also, in the case

that fine adjustment for squareness is required, select one of

these reamed holes to be used and adjust.

• Refer to the follow table for the screw depth and reamed hole

depth.

In the case that the screw is screwed in the hole to the depth more than the value in the following table, it

might cause a damage to the tapped hole or insufficient attachment strength of the object to be carried,

which may result in degradation of accuracy or unexpected accident.

Set Screw

Model A B C D

Screw Nominal

Diameter

Tightening Torque

TA3 24 5 10 M4 Depth 6 M4 1.76N·m(0.18kgf·m)

TA4 29 5 13 M5 Depth 6 M5 3.42N·m(0.35kgf·m)

TA5 29 6.5 14 M6 Depth 10 M6 5.36N·m(0.55kgf·m)

TA6 35 7 18 M6 Depth 13 M6 5.36N·m(0.55kgf·m)

TA7 44 6.5 21.5 M8 Depth 15 M8 11.48N·m(1.17kgf·m)

1.4 T-Groove

A T-groove is provided on the side of the main body of TA5C, 6C, 7C, 5R, 6R or 7R

to attach the external equipment (for M3). Use the groove freely for the sensor

attachment or fixing of wires, when necessary.

The dimensions of the groove are described as follows.

• For the nut used for the T-groove, a square nut is recommended, but a hexagon

nut can also be used.

• When it is attached, take care in selecting the bolt length so that the end of the

bolt does not touch the bottom section of the T-groove.

2. Total Length Short Type

2.1 Main Body Attachment

Fix it using the tapped hole on the rear side.

Description of the Set Screws

• For the base male set screw, use a hexagon socket head cap screw.

• For the bolt to be used, a high-tensile bolt complying with ISO-10.9 or more is recommended.

2.1.1 Compact Type

RCA2-TCA3NA, TCA3N (Lead Screw, Ball Screw), TCA4NA, TCA4N (Lead Screw, Ball Screw)

Tightening Torque

Model

Tap Size and

Max. Screw

Depth

Bolt to

be used

In the case that steel is

used for the bolt

seating surface:

In the case that

aluminum is used for the

bolt seating surface:

Slot

Reamed

Hole(mm)

TCA3NA, TCA3N

(Lead Screw,

Ball Screw)

M4 Depth 3 M4 3.59N·m(0.37kgf·m) 1.76N·m(0.18kgf·m)

A:3, B:4,

Depth: 3

φ3 Depth 3

TCA4NA, TCA4N

(Lead Screw,

Ball Screw)

M4 Depth 4 M4 3.59N·m(0.74kgf·m) 1.76N·m(0.35kgf·m)

A:3, B:4,

Depth: 3

φ3 Depth 3

Note : The tapped hole in the attachment section is partly a through hole. Never use the screw

longer than the screw effective length. Failure to do so may cause damage to inner

mechanism or electrical component.

Tightening Torque

Model

Tap Size and

Max. Screw

Depth

Bolt to

be used

In the case that steel is

used for the bolt

seating surface:

In the case that

aluminum is used for the

bolt seating surface:

Slot

Reamed

Hole(mm)

TC3N

(Lead Screw)

M4 Depth 3 M4 3.59N·m(0.37kgf·m) 1.76N·m(0.18kgf·m)

A:3, B:4,

Depth: 3

φ3 Depth 3

TC4N

(Lead Screw,

Ball Screw)

M4 Depth 4 M4 3.59N·m(0.74kgf·m) 1.76N·m(0.35kgf·m)

A:3, B:4,

Depth: 3

φ3 Depth 3

A

Table Type

A

B

C

3-D

5.5

1.8

5.8

3.3

2.7

A

R0.3 or less

Cable

Connector Cover

Main Body (Aluminum Frame)

Table

Right Side

Left Side

Front Plate

RearFront

Cable

Connector Cover

Main Body (Aluminum Frame)

Table

Right Side

Left Side

Front Plate

RearFront

Cable

Connector Cover

Main Body (Aluminum Frame)

Table

Right Side

Left Side

Front Plate

RearFront

Size A(mm)

2 to 4 or less

3 Depth 3

+0.05

0

Slot

2-M4 Depth 6

Tapped Hole

4-M4 Depth 4

Reamed Hole

195.5

4

10 30

25

30

22 4

223

(TC3N (Lead Screw) Ball Guide Type (Option: Model Code BG))

φ

3

Depth 3

+0.03

0

3 Depth 3

+0.05

0

26 4

34

4

4

6.5

21

30

15 30

Slot

Slot

2-M4 Depth 8

26

Tapped Hole

4-M4 Depth 5

Reamed Hole

(TC4N (Lead Screw), TC4N (Ball Screw) Ball Guide Type (Option: Model Code BG))

φ

3

Depth 3

+0.03

0

Actuator Cable

Connector Cover

Table

Right Side

Left Side

Rear

Connector Cover

Table

Actuator Cable

Right Side

Left Side

Rear

Table

Connector Cover

Right Side

Left Side

Rear

Actuator

Cable

Reamed Hole

Tapped Hole

4-M4 Depth 3

Slot

2-M4 Depth 6

22 4

30

22

3

4

19

5.5

3010

25

3 Depth 3

+0.05

0

+0.03

0

φ3 Depth 3

(TCA3NA, TCA3N (Lead Screw, Ball Screw))

Slot

A

B

4

216.5

25

10

30

Reamed Hole

Tapped Hole

4-M4 Depth 4

Slot

3 Depth 3

+0.05

0

3 Depth 3

+0.05

0

(TCA4NA, TCA4N (Lead Screw, Ball Screw))

2-M4, depth 8

4

26

14.9

26

9

4

34

Loading...

Loading...