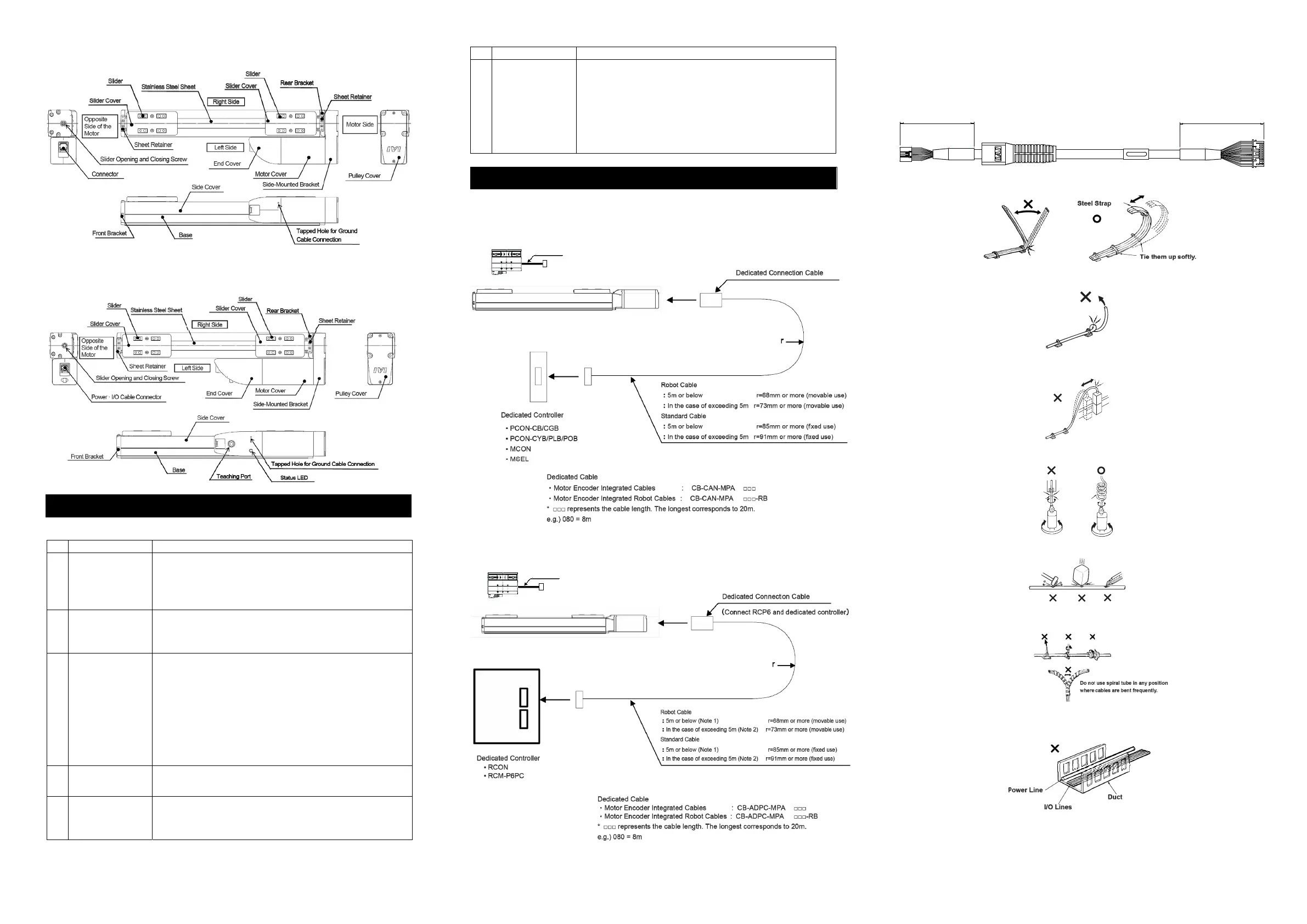

2.3 Standard Specification Motor Reversing Type

2.4 Built-in Controller Specification Motor Reversing Type

Attachment

Refer to the Instruction Manual (DVD) for the attachments of the actuator and loads.

[Precautions for Attachments]

No. Item Precautions

1 Installation

Long Stroke Gripper, it may cause slackness or misalignment of the

stainless steel sheet. Continued usage in this orientation may lead to

damage to the stainless steel sheet. Check the actuator daily and , make

installation adjustment of the stainless steel sheet. (Refer to the

maintenance section of instruction manual (DVD) for the “Procedure for

Stainless Steel Sheet Adjustment”])

2

Attachment Surface

Make sure that the surface to install the actuator and that used as the

datum are a well-finished machined surface or one that possesses an

accuracy equivalent to it.

Ensure a room for maintenance work.

3

Bolt to be used

For the bolts to be used, a high-tensile bolt complying with ISO-10.9 or

more is recommended.

If using the tapped holes, use screws with the thread length dimension

being less than the effective depth of the holes.

For the actuator mounting, use a bolt with the dimension of its effective

mating length to the tapped hole is as stated below.

If tapped hole on steel thread length same as nominal diameter

If tapped hole on aluminum maximum depth tapped hole

For a tapped hole with its depth at 1.8

times or more of the nominal diameter,

have 1.8 times or more of the nominal

diameter

4

Tightening Torque

Please follow the specification values stated in the Instruction Manual

(DVD) for the tightening torque.

Failure to do so may cause an operation problem.

5

Allowable Moment

Please follow the specification values stated in the Instruction Manual

(DVD) for the allowable moment.

Applying load exceeding the allowable moment may cause a drop in the

product life.

No. Item Precautions

6

Stainless Steel Sheet

Do not attempt to hold the stainless steel sheet on the long stroke

gripper directly with hand.

Also, pay attention not to make a dent mark on the stainless steel sheet.

As the stainless steel sheet is thin, it is easy to get a dent mark or

scratch. Using sheet with damage may cause it get broken.

Wipe off all dust and metal powers when they get on the stainless steel

sheet. Operation with stainless steel sheet with foreign obstacles on

could cause damage, waving or looseness on the sheet when it gets

pinched inside the fingers.

Do not work in an ambient that contain dust and metal powers.

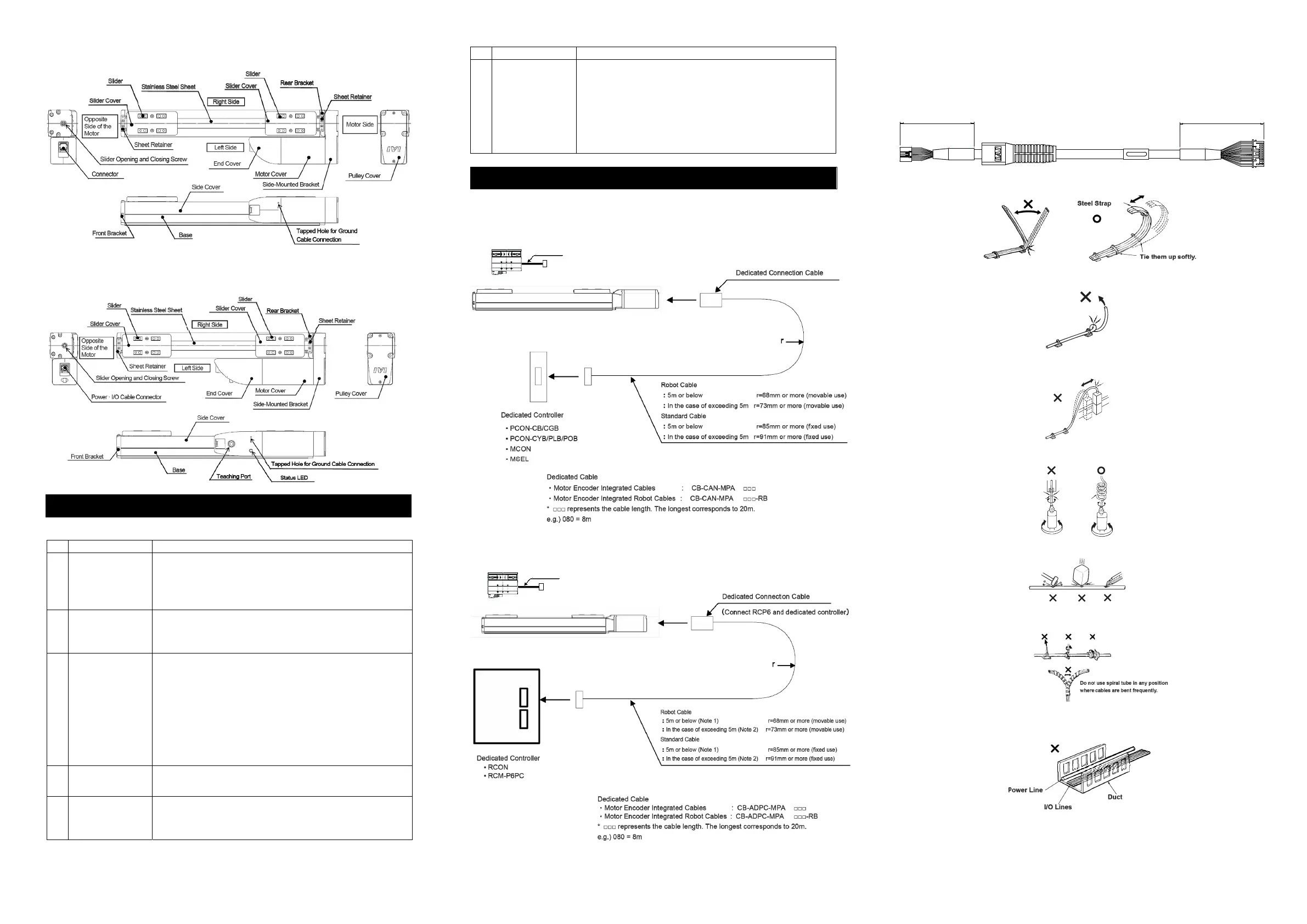

Wiring

For the controller, only the dedicated controller manufactured by our company can be used.

Using an undedicated controller may cause an accident such as burnout, combustion or heat generation.

Use the dedicated cable enclosed in the package when connecting the actuator and the controller.

[Prohibited Items in the Cable Processing]

Do not pull or bend forcibly the cable so as to give any extra load or tension to the cable.

Do not process the cable to extend or shortening by means of cutting out, combination or connecting

with another cable.

Do not bend the cable in the area from the connector tip inward to 150mm on both ends.

CB-CAN-MPA□□□, CB-CAN-MPA□□□-RB, CB-ADPC-MPA-□□□, CB-ADPC-MPA-□□□-RB

150mm 150mm

Do not let the cable flex at a single point.

Do not let the cable bend, kink or twist.

Do not pull the cable with a strong force

Do not let the cable receive a turning force at a single point.

Do not pinch, drop a heavy object onto or cut the cable.

When fixing the cable, provide a moderate slack and do not tension it too tight.

Separate the I/O line, communication line and power line from each other.

Do not store in the same duct.

RCP6-××

r 50mm

or more

RCP6-××

r 50mm

or more

Loading...

Loading...