INSTALLATION AND OPERATION INSTRUCTIONS

1-6

SL 35-199, SL 45-260 MODULATING GAS BOILERS

Use of cellular core PVC (ASTM F891), cellular core CPVC, or Radel®

(polyphenolsulfone) in venting systems shall be prohibited.

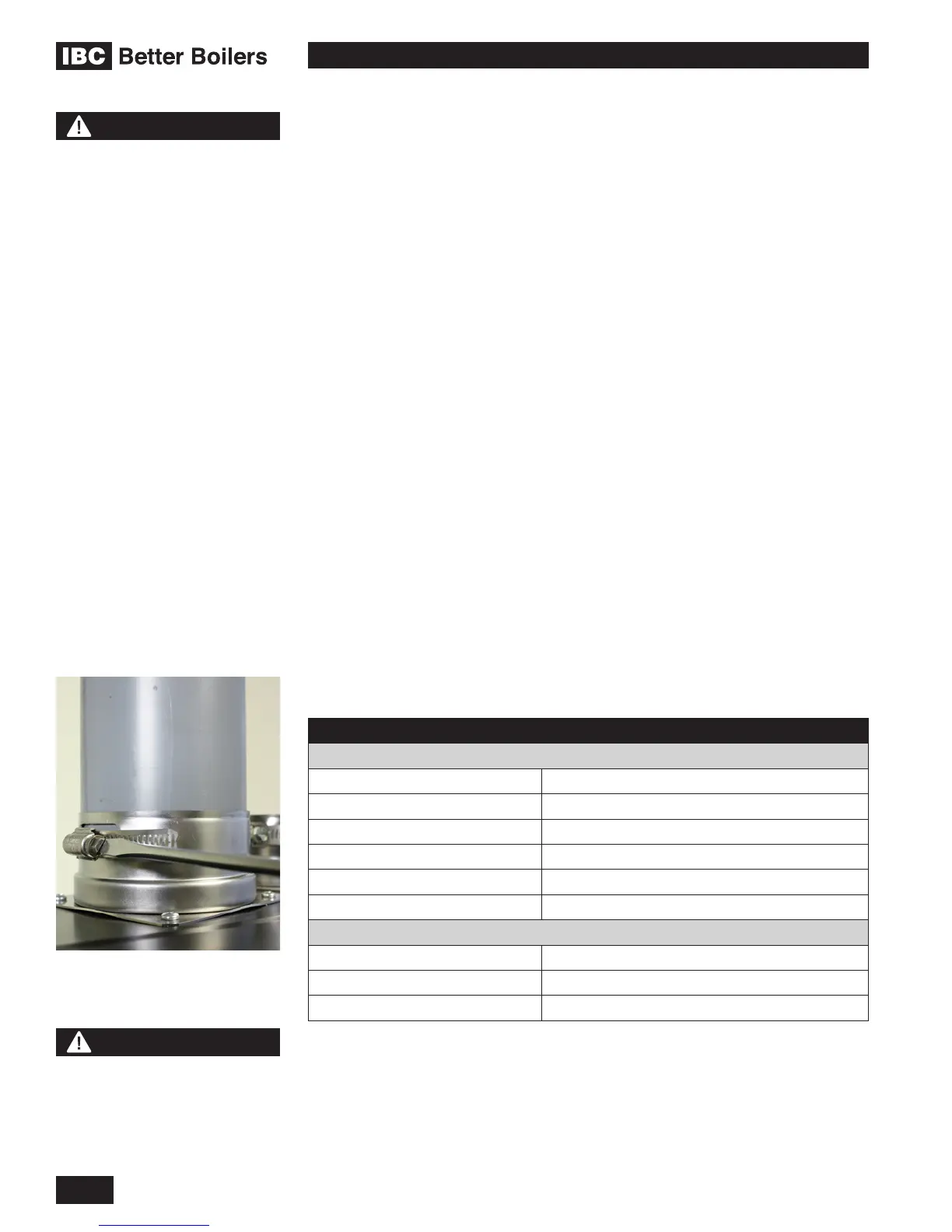

The boiler offers 3” venting connections. Fittings are to be used to adapt to the

appropriate diameter (see Vent Travel below). There are two stainless steel,

gasketedttingsonthetopoftheboiler.Exhaustventingistobeinserteddirectly

intothe3”femalestainlesssteelttingontheleft(see Figure 3).

ForPPsmaterial,usethe3”transition/adaptortting(Sch40toPPs)offered

by the respective PPs manufacturers Centrotherm / Innoue

TM

(their part #

ISAA0303) or M&G Dura Vent /PolyPro (#3PPS-AD). For PPs material exposed

to outdoor weather, follow the venting suppliers’ recommendations on UV

protection.

Combustion air piping - if used - is inserted directly into the 3” female stainless

steelttingontheright(see Section 1.4.7).

Venting shall be supported in accordance with applicable code.

*Manufacturers of stainless steel Type BH venting systems must submit

their approved transition tting to IBC for evaluation and written approval.

1.4.3 Vent Travel

CPVC or PPs (Rigid Single Wall) piping is the standard venting option; with

this, the SL 35-199 and SL 45-260 boilers, for example, can be sited up to

200 equivalent feet from the vent termination using 3”. The actual vent travel

allowanceisreducedforttingsinaccordancewithTable 3. – e.g. for SL 35-199

and SL 45-260 boilers using 6 x 90º CPVC elbows, the maximum lineal measure

of pipe allowed using 3” pipe is 152 feet (200’ – (6 x 8' = 48) = 152’).

For3”exiblePPs(SL35-199model),upto160actuallinealfeetareallowedin

anominallyverticalorientation(>45°).Theequivalentlengthof3”exPPsshall

be computed using a multiple of 1.2:1, eg. 45’ x 1.2 = 54’ equivalent. With 45’ of

3”ex,upto146’equivalentof3”rigidPPswouldstillbeallowed.

EXHAUST PIPE SIZE MAXIMUM EQUIVALENT LENGTH

Sched.40; Rigid PPs

3” 200’

4” 200’

90° long sweep elbow allow 5’ equivalent

90° vent elbow allow 8’ equivalent

45° elbow allow 3’ equivalent

PPs 87-90° elbows use 8’ equivalent

Flexible PPs

3” Flexible (SL 35-199) 160’ (max.) actual lineal x 1.2 = equivalent

3” PPs Flexible (SL 45-260) 60’ (max.) actual lineal x 3.33 = equivalent

4” Flexible 160’ (max.) actual lineal x 1.2 = equivalent

Table 3: Maximum exhaust venting length.

NOTE: Unused intake travel cannot be added to the exhaust. Unequal

intake and exhaust piping is allowed (see Section 1.4.8).

WARNING

Do not mix venting materials

from different Manufacturers.

These venting materials are

designed to be installed as

part of a complete system.

Failure to comply may result

in severe personal injury or

death.

WARNING

Fully insert the approved

venting material into the boilers

exhaust outlet and tighten

clamp to ensure the venting

connection is locked in place.

Loading...

Loading...