INSTALLATION AND OPERATION INSTRUCTIONS

1-18

SL 35-199, SL 45-260 MODULATING GAS BOILERS

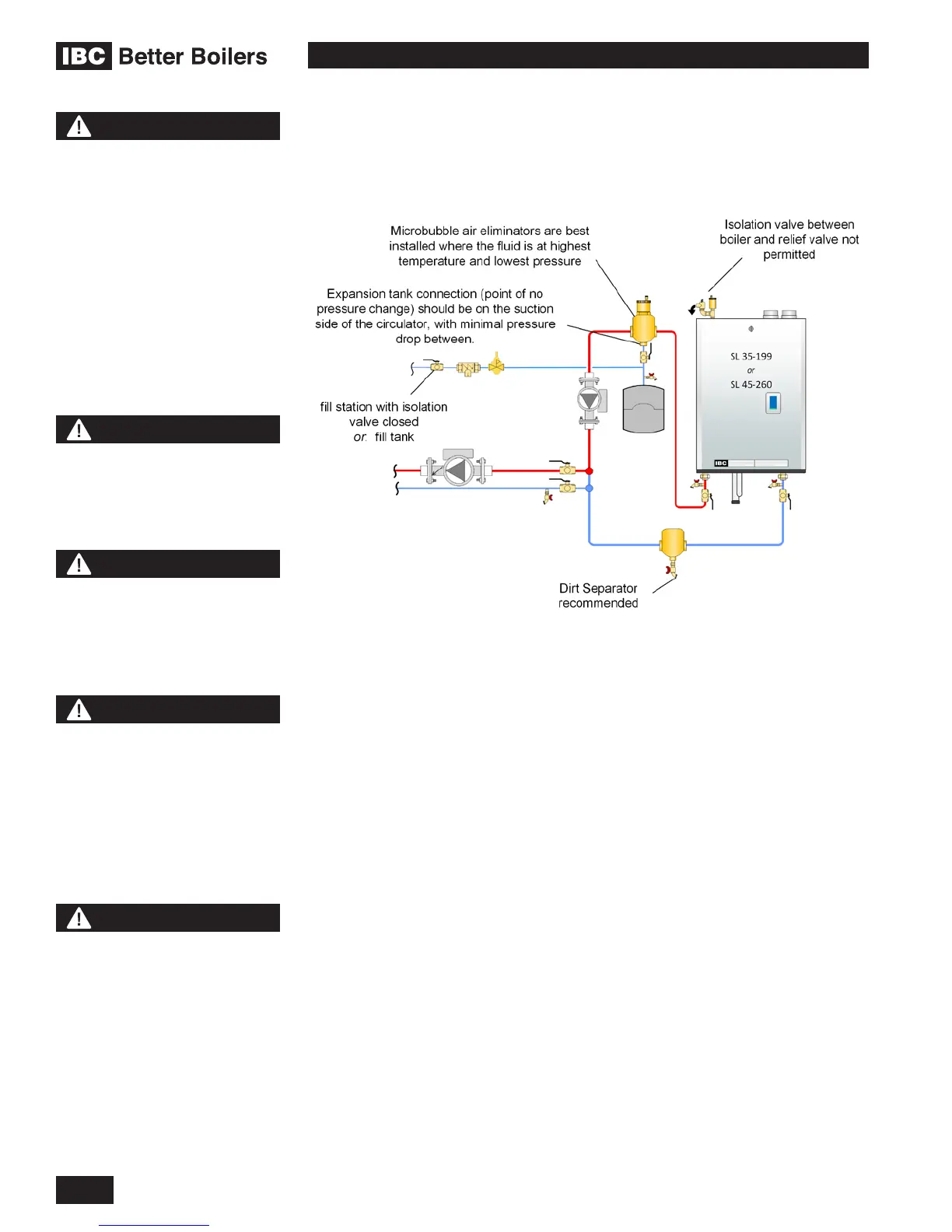

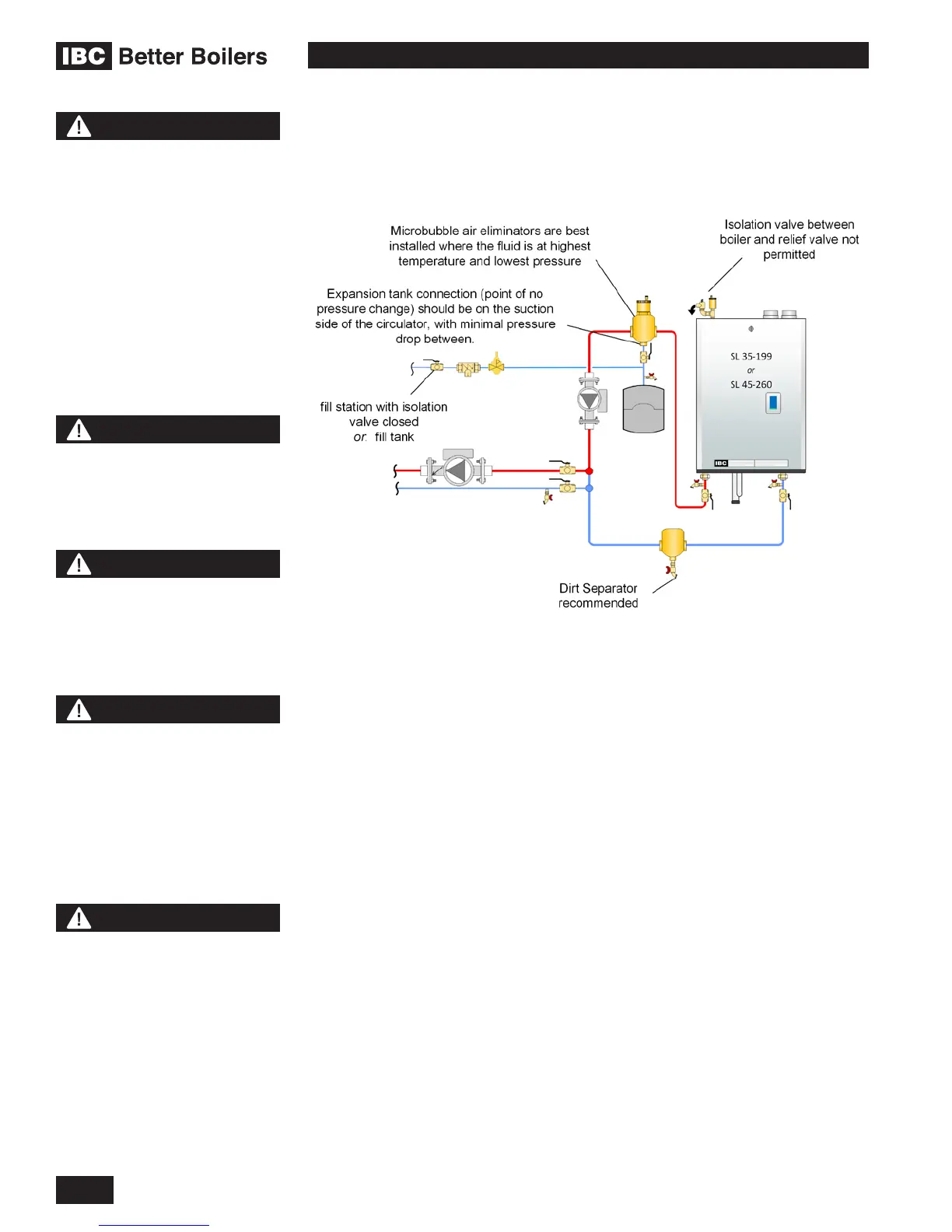

System piping is connected to the boiler using the 1-1/2” NPT Male threaded

ttingsonthebottomconnectionports.Unionsandgateorballvalvesatthe

boilers supply and return water connections are recommended to simplify

servicing. Un-insulated hot water pipes must be installed with a minimum 1/4”

clearance from combustible materials.

Fluidllismostoftenaccomplishedbyusingaboilerregulator&llvalveset

at12psigormore,withappropriatebackowpreventiondeviceasrequired

by local code. This is acceptable in areas where municipal water or well water

hasbeentreatedandlteredtoremoveexcessivemineralsandsediment,and

water chemistry is known to be suitable for closed loop hydronic systems. In

areas where water quality is in question, or when chemical treatment or glycol is

required, other options should be considered. Follow applicable Codes and good

piping practice.

There are a number of boiler feed and pressurization devices on the market

todaythatmaybeabetterchoicethanarawwaterllfromthemains.When

regular maintenance requires relief valve blow-off, the discharge may be directed

backintothepressurizationunitforrecyclingofboileruidandchemicals

back into the system. In buildings that may be unoccupied for long periods of

time,pressurizationunitsareusefultopreventooddamageshouldleakage

occurfromanycomponentinthesystem.Anadditionalbenetisthatbackow

prevention devices are not required when using these devices.

Do not place any water connections overhead the boiler; leaks can damage

the fan & controls. If needed, create a shield over the top of the cover, but allow

clearanceforairowandserviceaccess.

For best results, use a Primary: Secondary piping system, with a pumped boiler

loop using 1-1/2” piping for the SL 35-199 and SL 45-260. Heat exchanger head

is only 2’ at 6 USgpm and approximately 13’ at 25 USgpm.

Figure 22: Boiler trim basic options - side piping

WARNING

Close ll valve after any

addition of water to the

system, to reduce risk of

water escapement.

CAUTION

Installers should inquire of

local water purveyors as to

the suitability of their supply

for use in hydronic heating

systems. If water quality is

questionable, a local water

treatment expert must

be consulted for testing,

assessment and, if required,

treatment. Alternatively, water

or hydronic uid of known

quality can be brought to the

site.

NOTE

Full sized application

drawings can be downloaded

from our web site.

www.ibcboiler.com

NOTE

The boiler, when used in

connection with a refrigeration

system, must be installed so

the chilled medium is piped

in parallel with the boiler with

appropriate valves to prevent

the chilled medium from

entering the boiler.

NOTE

The boiler piping system of

a hot water boiler connected

to heating coils located in

air handling units where

they may be exposed to

refrigerated air circulation

must be equipped with

ow control valves or other

automatic means to prevent

gravity circulation of the

boiler water during the

cooling cycle.

Loading...

Loading...