Two- Stage Multi Position Furnace

Service

Manual

24

440 08 2002 02

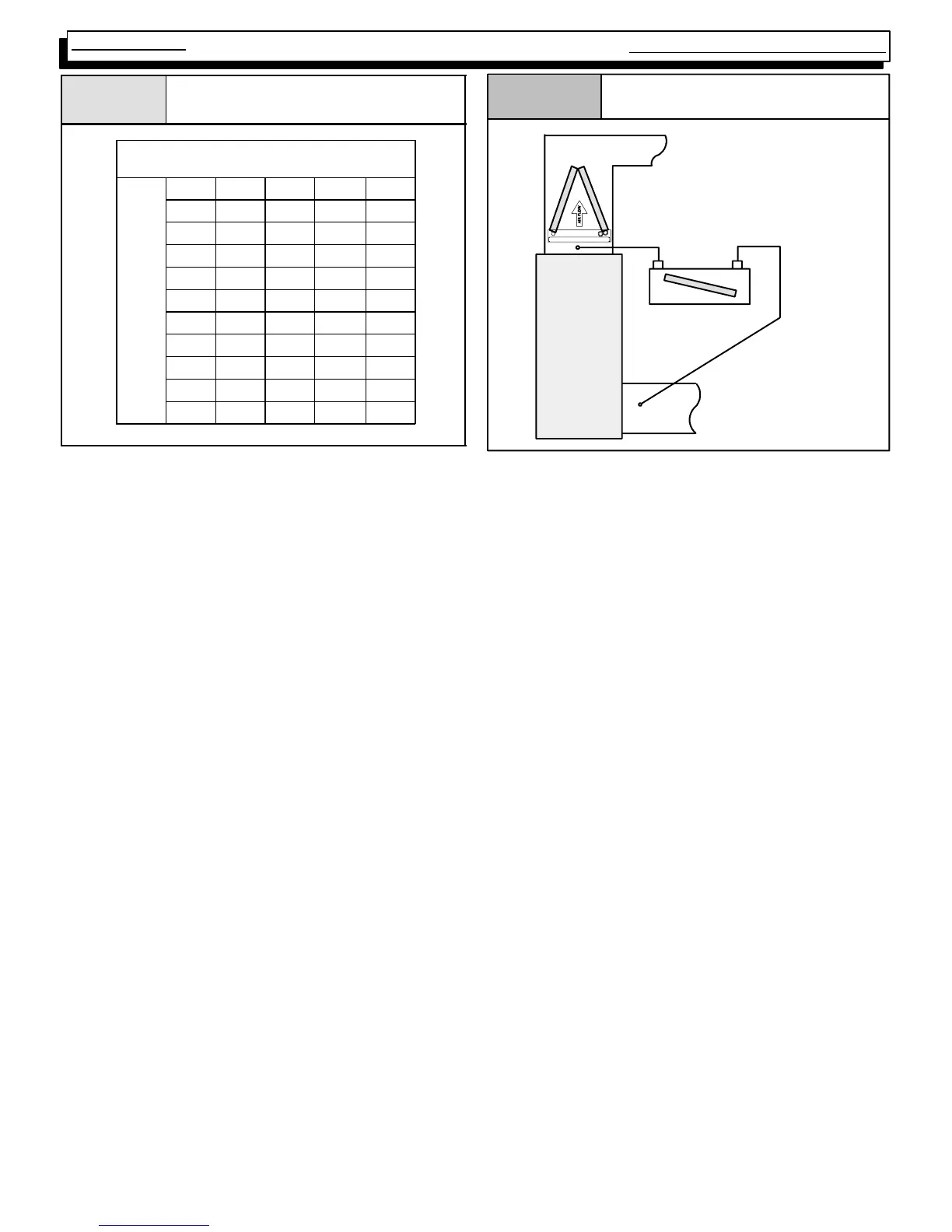

Table 7

Blower Performance Data 75,000

BTUH (PSC Motor)

Air Delivery in Cubic Feet per Minute (CFM)

(Furnace Rated @ 0.5² W.C. ESP)

TAP LOW MED L MED H HIGH

.10 706 917 1163 1368

.20 677 875 1120 1319

sure

.30 636 840 1076 1263

Pres

W.C.

.40 595 812 1031 1202

tatic

sof

.50 546 766 987 1148

al S

nche

.60 490 702 889 1077

xter

I

.70 -- -- -- 630 821 989

E

.80 -- -- -- 550 750 914

.90 -- -- -- 462 676 833

1.0 -- -- -- -- -- -- 601 747

Always check current “Technical Support Manual”

EXTERNAL STATIC PRESSURE (ESP)

External Static Pressure can best be defined as the pres-

sure difference (drop) between the Positive Pressure (dis-

charge) and the Negat ive Press ure (int ak e) sides of the

blower. E xternal St atic Pres sure is developed by the

blower as a result of resistance to airflow (Friction) in the

air distribution system EXTERNAL to the furnace cabinet.

(i.e pressure inside duct)

Resist anc e applied external l y to the furnace (I.E. Duct

work, Coils, Humidifiers, Filters, Etc.) on either the Supply

or Return side of the system, causes an INCREASE in Ex-

ternal Static Pressure, accompanied by a REDUCTION in

airflow.

ESP is affected by two (2) factors.

1. Resistance to Airflow as explained above.

2. Blower Speed. Changing to a higher or lower blower

speed tap will raise or lower the External Static Pres-

sure accordingly.

These effects MUST be understood and taken into consid-

eration when checking ESP/ Airflow to insure that the sys-

tem is operating within design conditions.

Operating a system with Insufficient or Excessive air f low

can cause a variety of different operating problems.

Among these are premat ure heat ing component and/or

compressor failures, reduced capacity, freezing evapora-

tor coils, etc.

System air flow should ALWAYS be verified upon comple-

tion of a new installation, or BEFORE a change--out, heat

exchanger replac ement , or in the case of a compr es sor

failure to insure that the failure was not caused by improp-

er air flow.

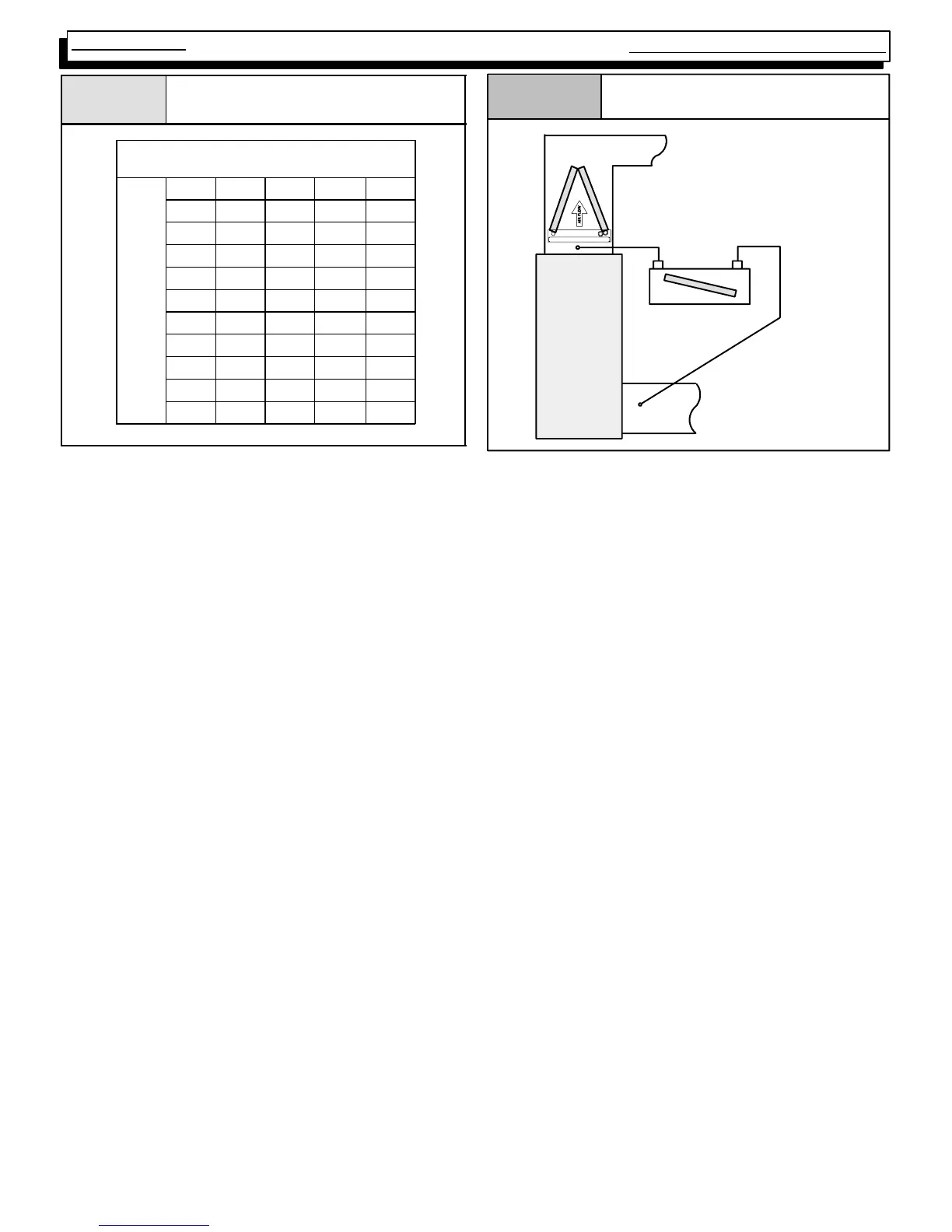

Figure 34

Checking Static Pressure

Supply

Indoor

Section

Inclined

Manometer

Return

CHECKING EXTERNAL STATIC PRESSURE

The air flow through the unit can be determined by measur-

ing the external static pressure of the system, and consulting

the blower performance data for the particular model furnace

you have.

1. Set up to measure ext ernal st at ic press ure at t he sup-

ply and return duct c onnect ions (See F igur e 34) .

2. Drill holes in the ducts for pressure taps, pitot tubes, or

other accurate pressure sensing devices.

3. Connect these taps to a level inclined manometer or

Magnehelic gauge.

4. Ensure the coil and filter are clean, and all the registers

are open.

5. Determine the external static pressure with the blower

operating.

6. Refer to the Air Flow Data for your particular furnace to

find the actual airflow for the current speed tap (or dip

switch setting).

7. If the Actual airflow is either too high, or too low, the

blower speed tap (or dip switch setting) will need to be

changed.

8. Refer to Changing Blower Speeds on the pages that fol-

low for the proper procedure.

9. Select the speed tap (or dip switch setting) that ap-

pears to most closely provide the required air flow for

the system.

10. Recheck the external static pressure with the new

speed tap. External static pressure (and actual air-

flow) will both have changed (either higher, or lower),

depending upon speed tap selected. Recheck the ac-

tual airflow (at this “new” static pressure) to confirm

speed tap selection.

11. Repeat steps 9. and 10. (if necessary) until proper

Speed Tap (and airflow) has been obtained.

Loading...

Loading...