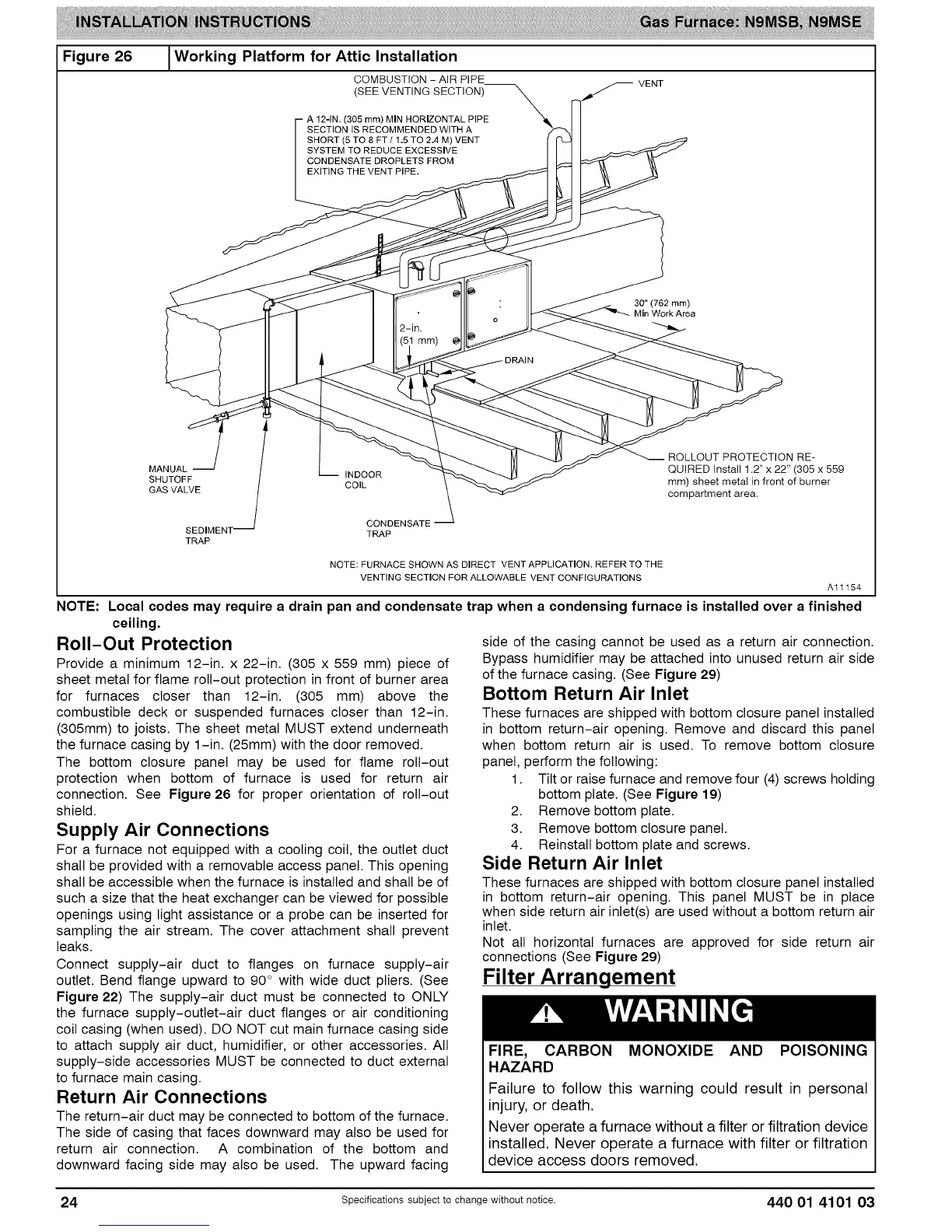

Figure 26 I Working Platform for Attic Installation

COMBUSTION - AIR PIPE VENT

(SEE VENTING SECTION)

(305 mm) MIN HORIZONTAL PIPE

SECTION IS RECOMMENDED WITH A

SHORT (5 TO 8 FT / 1.5 TO 2.4 M) VENT

SYSTEM TO REDUCE EXCESSIVE

CONDENSATE DROPLETS FROM

EXITING THE VENT PIPE.

30" (762 mm)

Min Work Area

INDOOR

COIL

CONDENSATE

TRAP

ROLLOUT PROTECTION RE-

QUIRED Install 1.2" x 22" (305 x 559

mm) sheet metal in front of burner

compartment area.

NOTE:

ceiling.

Roll-Out Protection

Provide a minimum 12-in. x 22-in. (305 x 559 mm) piece of

sheet metal for flame roll-out protection in front of burner area

for furnaces closer than 12-in. (305 mm) above the

combustible deck or suspended furnaces closer than 12-in.

(305mm) to joists. The sheet metal MUST extend underneath

the furnace casing by 1-in. (25mm) with the door removed.

The bottom closure panel may be used for flame roll-out

protection when bottom of furnace is used for return air

connection. See Figure 26 for proper orientation of roll-out

shield.

Supply Air Connections

For a furnace not equipped with a cooling coil, the outlet duct

shall be provided with a removable access panel. This opening

shall be accessible when the furnace is installed and shall be of

such a size that the heat exchanger can be viewed for possible

openings using light assistance or a probe can be inserted for

sampling the air stream. The cover attachment shall prevent

leaks.

Connect supply-air duct to flanges on furnace supply-air

outlet. Bend flange upward to 90° with wide duct pliers. (See

Figure 22) The supply-air duct must be connected to ONLY

the furnace supply-outlet-air duct flanges or air conditioning

coil casing (when used). DO NOT cut main furnace casing side

to attach supply air duct, humidifier, or other accessories. All

supply-side accessories MUST be connected to duct external

to furnace main casing.

Return Air Connections

The return-air duct may be connected to bottom of the furnace.

The side of casing that faces downward may also be used for

return air connection. A combination of the bottom and

downward facing side may also be used. The upward facing

NOTE: FURNACE SHOWN AS DIRECT VENT APPLICATION. REFER TO THE

VENTING SECTION FOR ALLOWABLE VENT CONFIGURATIONS

A1ff54

Local codes may require a drain pan and condensate trap when a condensing furnace is installed over a finished

side of the casing cannot be used as a return air connection.

Bypass humidifier may be attached into unused return air side

of the furnace casing. (See Figure 29)

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed

in bottom return-air opening. Remove and discard this panel

when bottom return air is used. To remove bottom closure

panel, perform the following:

1. Tilt or raise furnace and remove four (4) screws holding

bottom plate. (See Figure 19)

2. Remove bottom plate.

3. Remove bottom closure panel.

4. Reinstall bottom plate and screws.

Side Return Air Inlet

These furnaces are shipped with bottom closure panel installed

in bottom return-air opening. This panel MUST be in place

when side return air inlet(s) are used without a bottom return air

inlet.

Not all horizontal furnaces are approved for side return air

connections (See Figure 29)

Filter Arrangement

FIRE, CARBON MONOXIDE AND POISONING

HAZARD

Failure to follow this warning could result in personal

injury, or death.

Never operate a furnace without a filter or filtration device

installed. Never operate a furnace with filter or filtration

device access doors removed.

24 specificationssubjectto change without notice. 440 01 4101 03

Loading...

Loading...