Poison carbon monoxide gas hazard.

If this furnace is replacing a previously common-

vented furnace, it may be necessary to resize the

existing chimney liner or vent to prevent over sizing

problems for the other remaining appliances(s). See

codes of country having jurisdiction.

Failure to properly vent this furnace or other

appliances can result in property damage, personal

injury and/or death.

Ventingand CombustionAir Check

NOTE: If this installation removes an existing furnace from a vent-

ing system serving one or more other appliances, and to make

sure there is adequate combustion air for all appliances, MAKE

THE FOLLOWING CHECK.

1. Seal any unused openings in the venting system.

2.

Visually inspect the venting system for proper size and hori-

zontal pitch to ensure there is no blockage or restriction, leak-

age, corrosion or other deficiencies which could cause an

unsafe condition.

8.

Insofar as is practical, close all doors and windows and all

doors between the space in which the appliance(s) remain-

ing connected to the venting system are located and other

spaces of the building.

4.

Turn on clothes dryers and any appliance not connected to

the venting system. Turn on any exhaust fans, such as range

hoods and bathroom exhausts, so they will operate at maxi-

mum speed. Do not operate a summer exhaust fan. Close

fireplace dampers.

5. Follow the lighting instructions for each appliance being in-

spected. Adjust thermostat so appliance(s) will operate con-

tinuously.

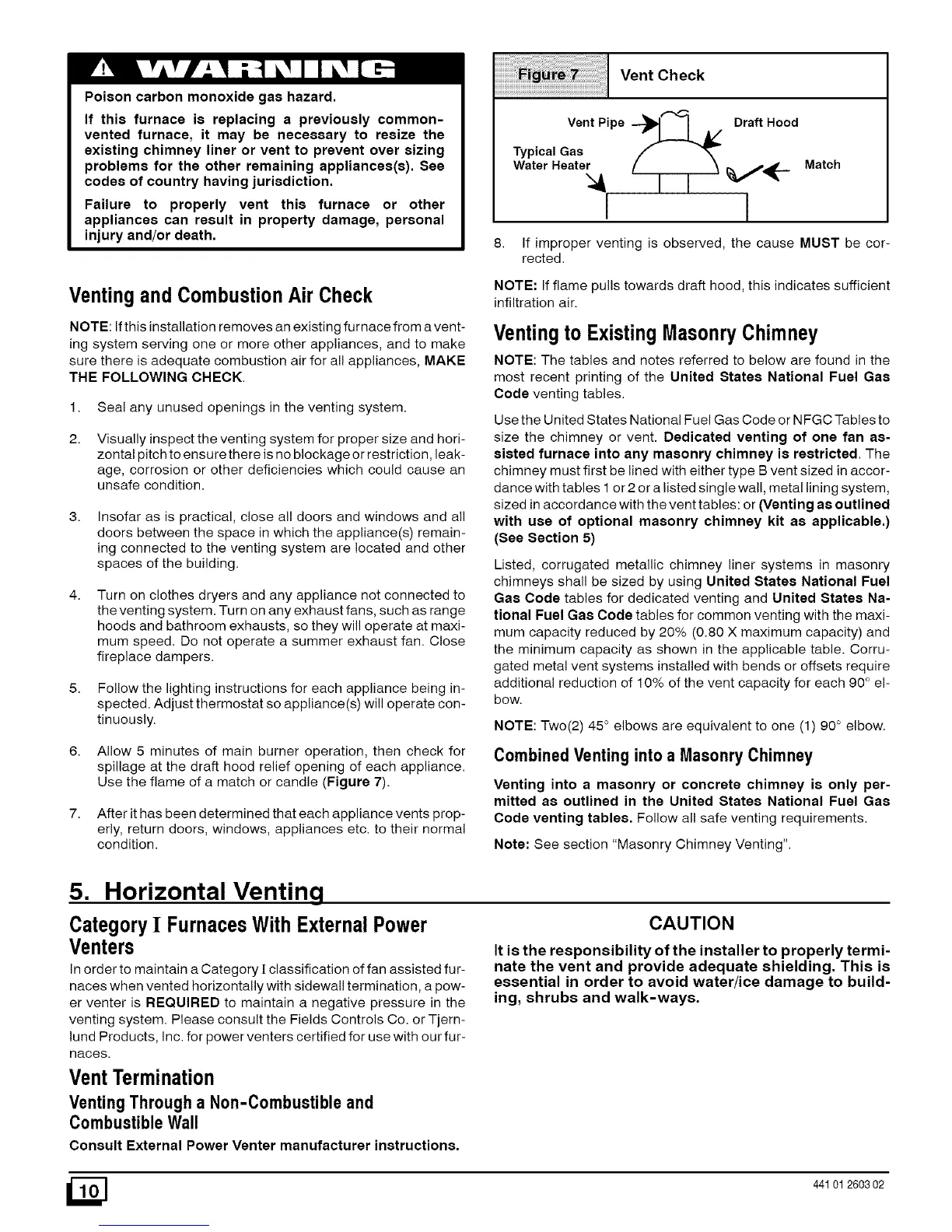

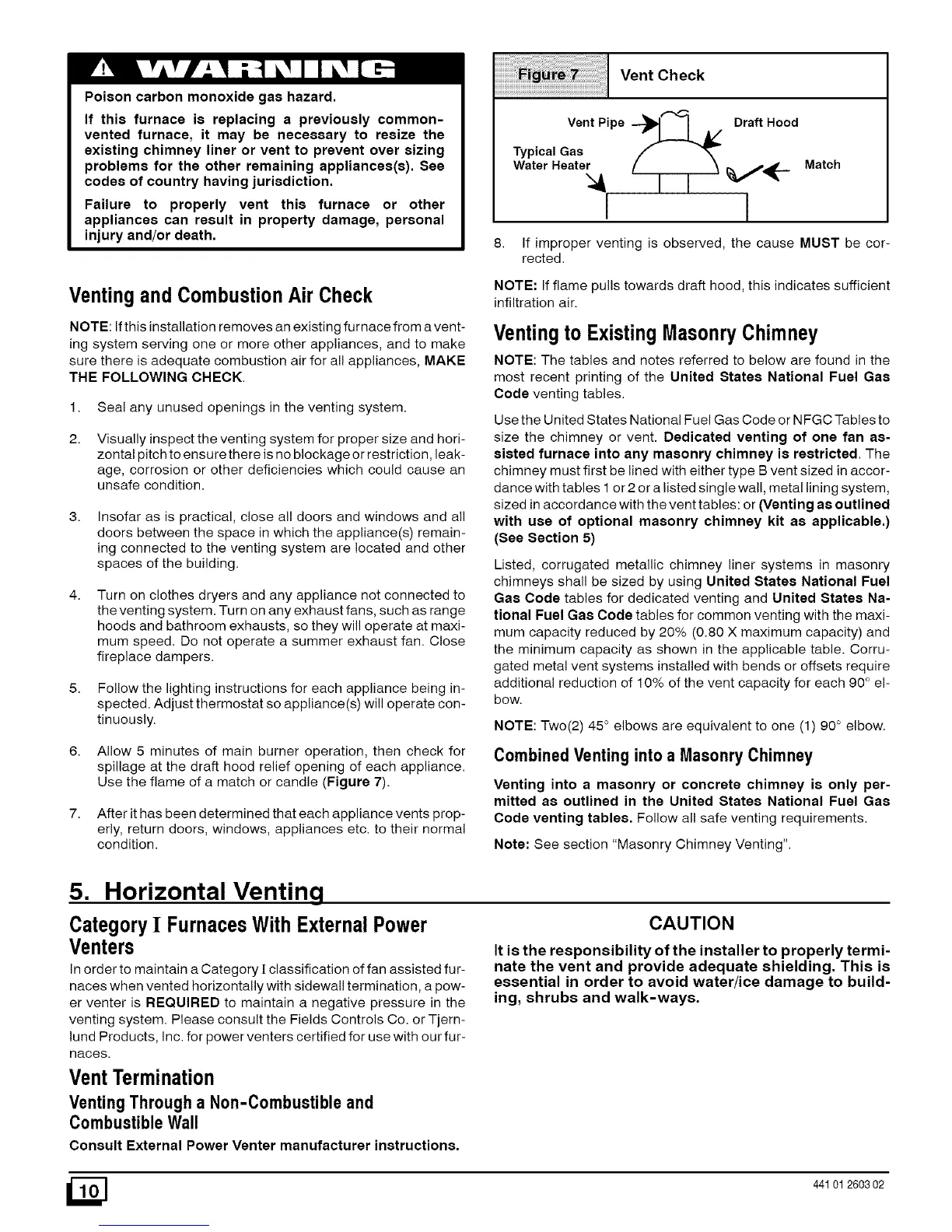

6. Allow 5 minutes of main burner operation, then check for

spillage at the draft hood relief opening of each appliance.

Use the flame of a match or candle (Figure 7).

7. After it has been determined that each appliance vents prop-

erly, return doors, windows, appliances etc. to their normal

condition.

Vent Check

Vent Pipe "_ I A/ Draft Hood

Typical Gas

Water Heater

I 1

Match

8. If improper venting is observed, the cause MUST be cor-

rected.

NOTE: If flame pulls towards draft hood, this indicates sufficient

infiltration air.

Ventingto Existing MasonryChimney

NOTE: The tables and notes referred to below are found in the

most recent printing of the United States National Fuel Gas

Code venting tables.

Use the United States National Fuel Gas Code or NFGC Tables to

size the chimney or vent. Dedicated venting of one fan as-

sisted furnace into any masonry chimney is restricted, The

chimney must first be lined with either type B vent sized in accor-

dance with tables 1 or 2 or a listed single wall, metal lining system,

sized in accordance with the vent tables: or (Venting as outlined

with use of optional masonry chimney kit as applicable.)

(See Section 5)

Listed, corrugated metallic chimney liner systems in masonry

chimneys shall be sized by using United States National Fuel

Gas Code tables for dedicated venting and United States Na-

tional Fuel Gas Code tables for common venting with the maxi-

mum capacity reduced by 20% (0.80 X maximum capacity) and

the minimum capacity as shown in the applicable table. Corru-

gated metal vent systems installed with bends or offsets require

additional reduction of 10% of the vent capacity for each 90 ° e!-

bow.

NOTE: Two(2) 45 ° elbows are equivalent to one (1) 90 ° elbow.

Combined Ventinginto a Masonry Chimney

Venting into a masonry or concrete chimney is only per-

mitted as outlined in the United States National Fuel Gas

Code venting tables. Follow all safe venting requirements.

Note: See section "Masonry Chimney Venting".

5. Horizontal Venting

CategoryI FurnacesWith ExternalPower

Venters

In order to maintain a Category ][ classification of fan assisted fur-

naces when vented horizontally with sidewall termination, a pow-

er venter is REQUIRED to maintain a negative pressure in the

venting system. Please consult the Fields Controls Co. or Tjern-

lund Products, Inc. for power venters certified for use with our fur-

naces.

CAUTION

It is the responsibility of the installer to properly termi-

nate the vent and provide adequate shielding, This is

essential in order to avoid water/ice damage to build-

ing, shrubs and walk-ways.

VentTermination

Venting Through a Non-Combustible and

CombustibleWall

Consult External Power Venter manufacturer instructions.

441 012603 02

Loading...

Loading...