7. Gas Supply and Piping

Poison carbon monoxide gas, fire and explosion hazard.

Models designated for Natural Gas are to be used with

Natural Gas ON LY,unless properly converted to use with

LP gas.

Failure to follow these instructions can result in death,

personal injury and/or property damage.

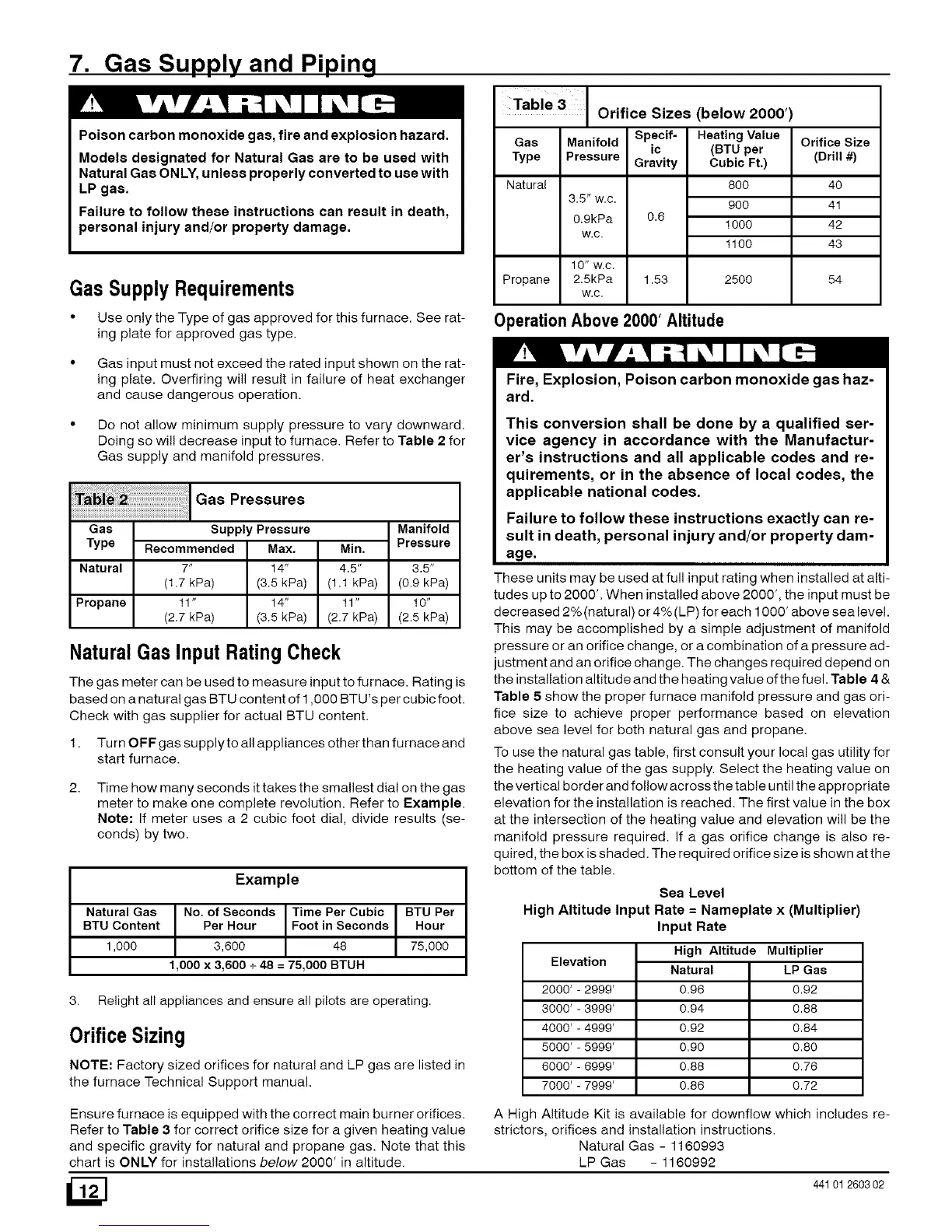

Table 3

Orifice Sizes (below 2000')

Gas Manifold Spacif- Heating Value

ic (BTU par

Type Pressure Gravity Cubic Ft.)

Natural

Propane

Gas SupplyRequirements

80O

3.5" w.c.

90O

0.9kPa 0.6

1000

w.c.

1100

10" w.c.

2.5kPa 1.53

w.c.

2500

Orifice Size

(Drill #)

4O

41

42

43

54

• Use only the Type of gas approved for this furnace. See rat-

ing plate for approved gas type.

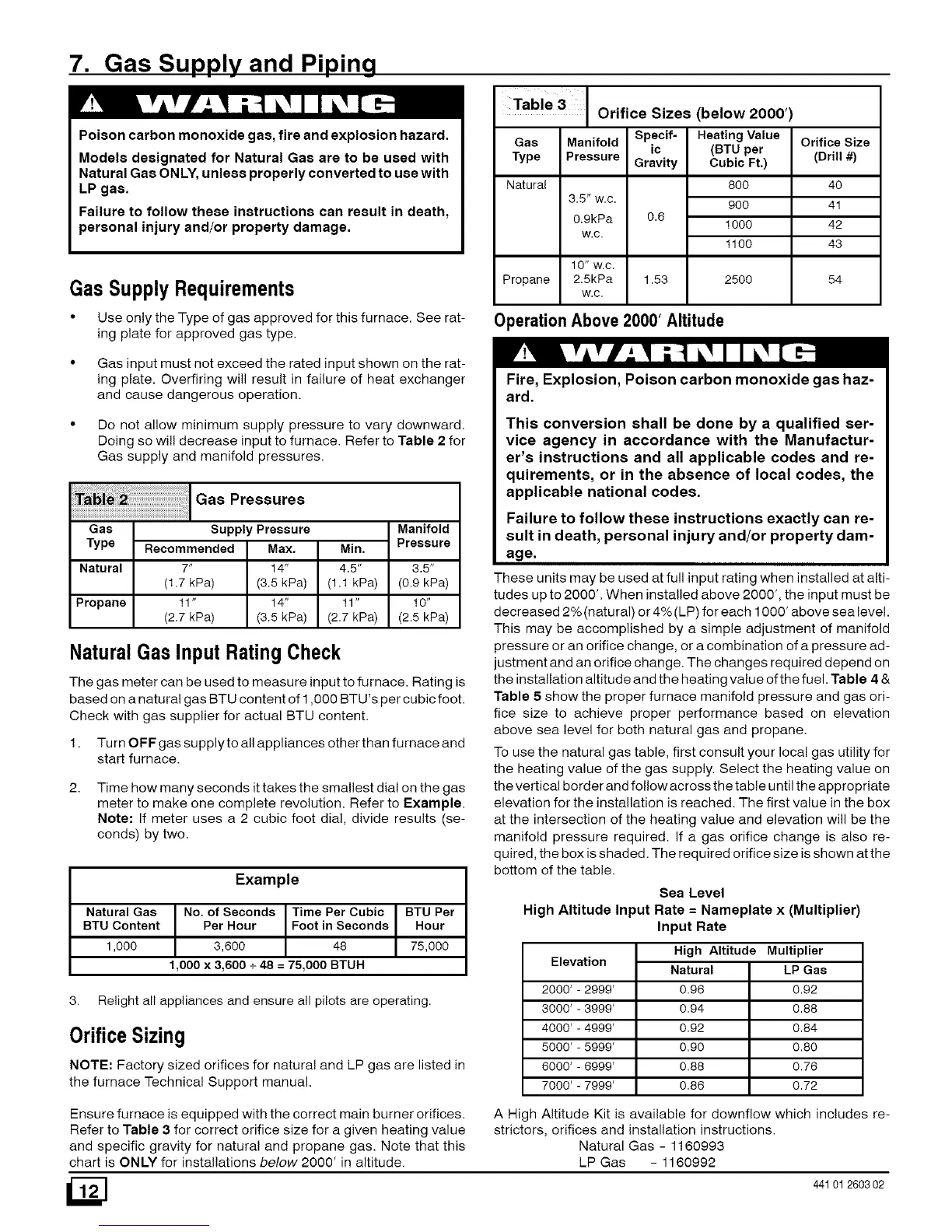

Operation Above 2000' Altitude

Gas input must not exceed the rated input shown on the rat-

ing plate. Overfiring will result in failure of heat exchanger

and cause dangerous operation.

Do not allow minimum supply pressure to vary downward.

Doing so will decrease input to furnace. Refer to Table 2 for

Gas supply and manifold pressures.

Pressures

Gas

Type

Natural

Manifold

Pressure

Supply Pressure

Recommended Max.

7" 14"

(1.7 kPa) (3.5 kPa)

11" 14"

(2.7 kPa) (3.5 kPa)

Min.

4.5" 3.5"

(1,1 kPa) (0.9 kPa)

Propane 11" 10"

(2.7 kPa) (2.5 kPa)

NaturalGas Input RatingCheck

The gas meter can be used to measure input to furnace. Rating is

based on a natural gas BTU content of 1,000 BTU's per cubic foot.

Check with gas supplier for actual BTU content.

1. Turn OFF gas supplyto all appliances otherthan furnace and

start furnace.

2.

Time how many seconds it takes the smallest dial on the gas

meter to make one complete revolution. Refer to Example.

Note: If meter uses a 2 cubic foot dial, divide results (se-

conds) by two.

Example

Natural Gas No. of Seconds Time Per Cubic BTU Par

BTU Content Per Hour Foot in Seconds Hour

1,000 3,600 48 75,000

1,000 x 3,600 + 48 = 75,000 BTUH

3. Relight all appliances and ensure all pilots are operating.

OrificeSizing

NOTE: Factory sized orifices for natural and LP gas are listed in

the furnace Technical Support manual.

Fire, Explosion, Poison carbon monoxide gas haz-

ard.

This conversion shall be done by a qualified ser-

vice agency in accordance with the Manufactur-

er's instructions and all applicable codes and re-

quirements, or in the absence of local codes, the

applicable national codes.

Failure to follow these instructions exactly can re-

sult in death, personal injury and/or property dam-

age.

These units may be used at full input rating when installed at alti-

tudes up to 2000'. When installed above 2000', the input must be

decreased 2% (natural) or 4%(LP) for each 1000' above sea level.

This may be accomplished by a simple adjustment of manifold

pressure or an orifice change, or a combination of a pressure ad-

justment and an orifice change. The changes required depend on

the installation altitude and the heating value of the fuel. Table 4 &

Table 5 show the proper furnace manifold pressure and gas ori-

fice size to achieve proper performance based on elevation

above sea level for both natural gas and propane.

To use the natural gas table, first consult your local gas utility for

the heating value of the gas supply. Select the heating value on

the vertical border and follow across the table until the appropriate

elevation for the installation is reached. The first value in the box

at the intersection of the heating value and elevation will be the

manifold pressure required. If a gas orifice change is also re-

quired, the box is shaded. The required orifice size is shown atthe

bottom of the table.

Sea Level

High Altitude Input Rate -- Nameplate x (Multiplier)

Elevation

2000'-2999'

3000'-3999'

4000'-4999'

5000'-5999'

6000'-6999'

7000'-7999'

Input Rate

High Altitude Multiplier

Natural LP Gas

0.96 0.92

0.94 0.88

0.92 0.84

0.90 0.80

0.88 0.76

0.86 0.72

Ensure furnace is equipped with the correct main burner orifices.

Refer to Table 3 for correct orifice size for a given heating value

and specific gravity for natural and propane gas. Note that this

chart is ONLY for installations below 2000' in altitude.

/2N

A High Altitude Kit is available for downflow which includes re-

strictors, orifices and installation instructions.

Natural Gas - 1160993

LP Gas - 1160992

441 01260302

Loading...

Loading...