AdjustPilot Burner

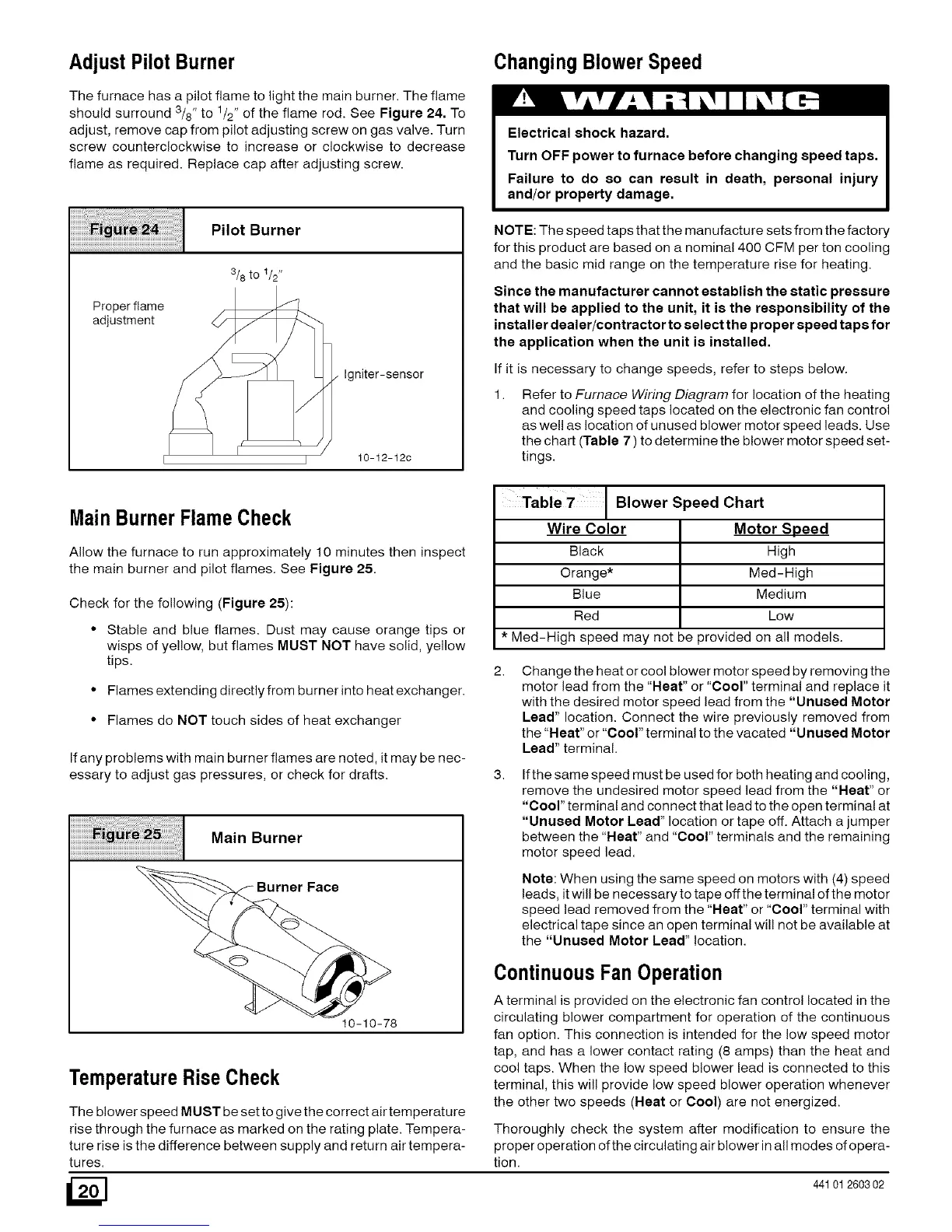

The furnace has a pilot flame to light the main burner. The flame

should surround 3/8" to 1/2" of the flame rod. See Figure 24. To

adjust, remove cap from pilot adjusting screw on gas valve. Turn

screw counterclockwise to increase or clockwise to decrease

flame as required. Replace cap after adjusting screw.

iiiiiiiiiiiiiiiiJ!;iiiiiiiiiil¸ ;i ;;;;;;;;;;!!ii ¸ ;;;;;

Proper flame

adjustment

Pilot Burner

3/8to 1/2"

Igniter-sensor

I 10-12-12c

ChangingBlowerSpeed

Electrical shock hazard.

Turn OFF power to furnace before changing speed taps.

Failure to do so can result in death, personal injury

and/or property damage.

NOTE: The speed taps that the manufacture sets from the factory

for this product are based on a nominal 400 CFM per ton cooling

and the basic mid range on the temperature rise for heating.

Since the manufacturer cannot establish the static pressure

that will be applied to the unit, it is the responsibility of the

installer deal er/contractor to select the proper speed taps for

the application when the unit is installed.

If it is necessary to change speeds, refer to steps below.

1. Refer to Furnace Wiring Diagram for location of the heating

and cooling speed taps located on the electronic fan control

as well as location of unused blower motor speed leads. Use

the chart (Table 7) to determine the blower motor speed set-

tings.

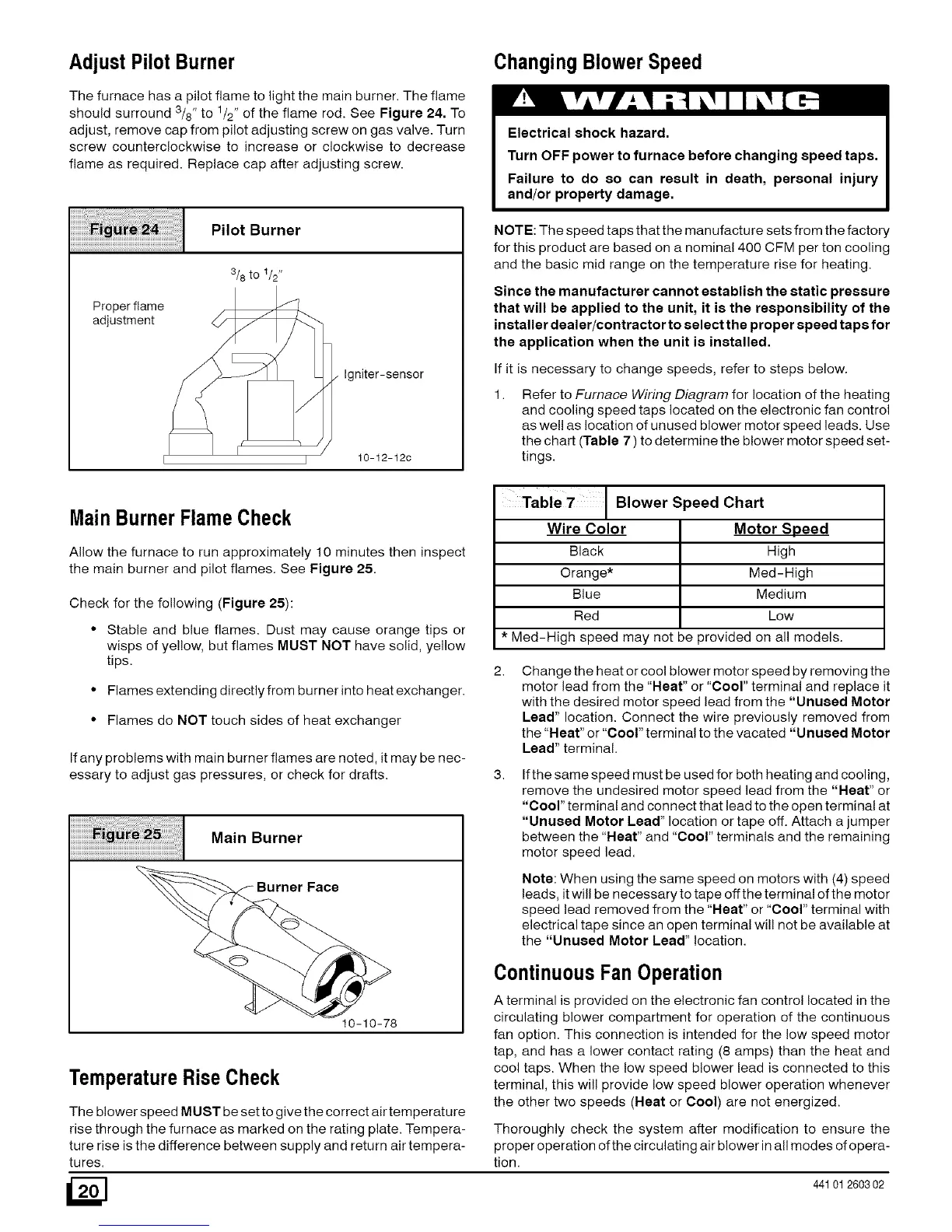

Main BurnerFlameCheck

Allow the furnace to run approximately 10 minutes then inspect

the main burner and pilot flames. See Figure 25.

Check for the fol!owing (Figure 25):

• Stable and blue flames. Dust may cause orange tips or

wisps of yellow, but flames MUST NOT have solid, yellow

tips.

• Flames extending directly from burner into heat exchanger.

• Flames do NOT touch sides of heat exchanger

If any problems with main burner flames are noted, it may be nec-

essary to adjust gas pressures, or check for drafts.

Main Burner

10-10-78

TemperatureRiseCheck

The blower speed MUST be set to give the correct air temperature

rise through the furnace as marked on the rating plate. Tempera-

ture rise is the difference between supply and return air tempera-

tures.

IN

Blower Speed Chart

Wire Color

Black

Orange*

Blue

Red

Motor Speed

High

Med-High

Medium

low

* Med-High speed may not be provided on all models.

Change the heat or cool blower motor speed by removing the

motor lead from the "Heat" or "Cool" terminal and replace it

with the desired motor speed lead from the "Unused Motor

Lead" location. Connect the wire previously removed from

the "Heat" or "Cool" terminal to the vacated "Unused Motor

Lead" terminal.

If the same speed must be used for both heating and cooling,

remove the undesired motor speed lead from the "Heat" or

"Cooi"terminal and connect that lead to the open terminal at

"Unused Motor Lead" location or tape off. Attach a jumper

between the "Heat" and "Cool" terminals and the remaining

motor speed lead.

Note: When using the same speed on motors with (4) speed

leads, it will be necessary to tape off the terminal of the motor

speed lead removed from the "Heat" or "Cool" terminal with

electrical tape since an open terminal wi!! not be available at

the "Unused Motor Lead" location.

ContinuousFanOperation

A terminal is provided on the electronic fan control located in the

circulating blower compartment for operation of the continuous

fan option. This connection is intended for the low speed motor

tap, and has a lower contact rating (8 amps) than the heat and

cool taps. When the low speed blower lead is connected to this

terminal, this will provide low speed blower operation whenever

the other two speeds (Heat or Cool) are not energized.

Thoroughly check the system after modification to ensure the

proper operation of the circulating air blower in all modes of opera-

tion.

441 012603 02

Loading...

Loading...