Ductwork installed in attic, or exposed to outside tempera-

tures requires a minimum of 2" of insulation with outdoor type

vapor barrier.

Ductwork installed in an indoor unconditioned space re-

quires a minimum of 1" of insulation with indoor type vapor

barrier.

Filters

A filter MUST be used:

Filters are not supplied with these furnaces, but can be purchased

from your dealer.

Use either filter type:

• Washable, high velocity filters are based on a maximum air

flow rating of 600 FPM.

• Disposable, Iowvelocity filters are based on a maximum air

flow of 300 FPM when used with filter grille.

• The furnaces, with 1600 or less CFM rating use a 16" x 25"

high velocity filter. On these models the filter may be

mounted internally for bottom return using factory kit or ex-

ternally for side return.

• The furnaces with greater than 1600 CFM requires that

both !eft and right side returns are used in side return ap-

plications. Two 16" x 25" high velocity filters and racks are

provided with furnace. Filter racks must be mounted exter-

nally. !f return air must be on one side only. an optional 20" x

25" filter standoff rack kits can be used. (See Figure 17)

For bottom return, an optional 20" x 25" filter rack kit can be

mounted internally.

10. Ductwork and Filter (Downflow)

Fire or explosion hazard.

Use sub-base for downflow installation on combustible

floors.

Failure to use sub-base on combustible floors can result

in death, bodily injury and/or property damage.

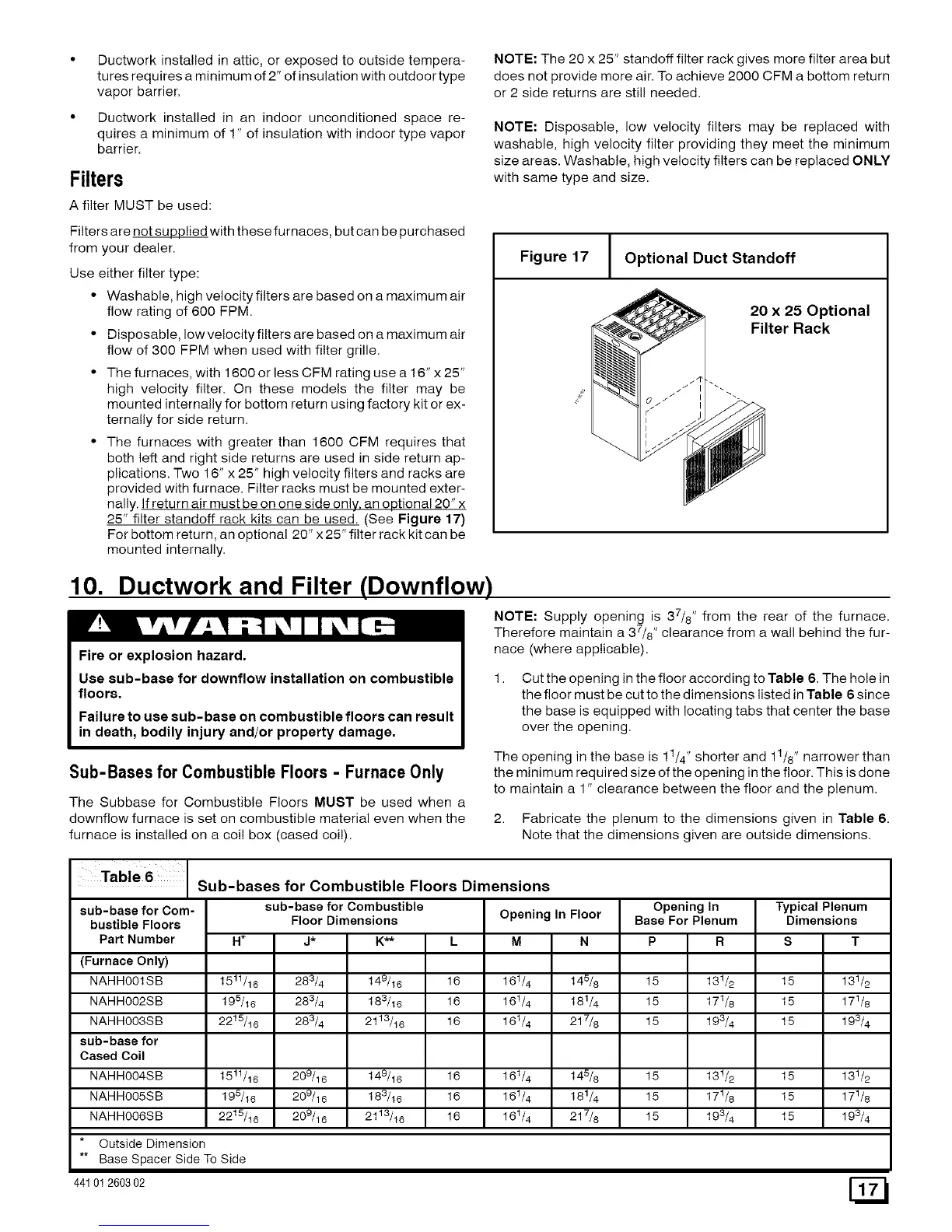

Sub-Bases for CombustibleFloors - Furnace Only

The Subbase for Combustible Floors MUST be used when a

downflow furnace is set on combustible material even when the

furnace is installed on a col! box (cased col!).

NOTE: The 20 x 25" standoff filter rack gives more filter area but

does not provide more air. To achieve 2000 CFM a bottom return

or 2 side returns are still needed.

NOTE: Disposable, low velocity filters may be replaced with

washable, high velocity filter providing they meet the minimum

size areas. Washable, high velocity filters can be replaced ONLY

with same type and size.

Figure 17

1

Optional Duct Standoff

20 x 25 Optional

Filter Rack

NOTE: Supply opening is 37/8" from the rear of the furnace.

Therefore maintain a 37/8" clearance from a wall behind the fur-

nace (where applicable).

Cut the opening in the floor according to Table 6. The hole in

the floor must be cut to the dimensions listed in Table 6 since

the base is equipped with locating tabs that center the base

over the opening.

The opening in the base is 1t/4" shorter and 1t/8" narrower than

the minimum required size of the opening in the floor. This is done

to maintain a 1" clearance between the floor and the plenum.

2. Fabricate the plenum to the dimensions given in Table 6.

Note that the dimensions given are outside dimensions.

Sub-bases for Combustible Floors Dimensions

H _

15tl/16

195/16

22t5/16

15tl/16

195/I6

22t5/16

sub-base for Com-

bustible Floors

Part Number

(Furnace Only)

NAHHOOlSB

NAHHOO2SB

NAHHOO3SB

sub-base for

Cased Coil

NAHHOO4SB

NAHHOO5SB

NAHHOOSSB

* Outside Dimension

sub-base for Combustible

Floor Dimensions

J* K**

283/4 149/16

283/4 183/16

283/4 2113/16

209/16 149/I6

209/16 183/I6

209/16 2113/16

Opening In Floor

L M N

16 161/4 145/8

16 161/4 181/4

16 161/4 217/8

16 161/4 145/8

16 161/4 181/4

16 161/4 217/8

Opening In

Base For Plenum

Typical Plenum

Dimensions

15

15

15

P R

15 13t/2

15 17t/8

15 193/4

15 13t/2

15 17t/8

15 193/4

15

15

15

131/2

171/8

193/4

131/2

171/8

193/4

** Base Spacer Side To Side

44101260302

Loading...

Loading...