1.0 EVOMAX CASCADE FLUE SYSTEM

1.1 INTRODUCTION

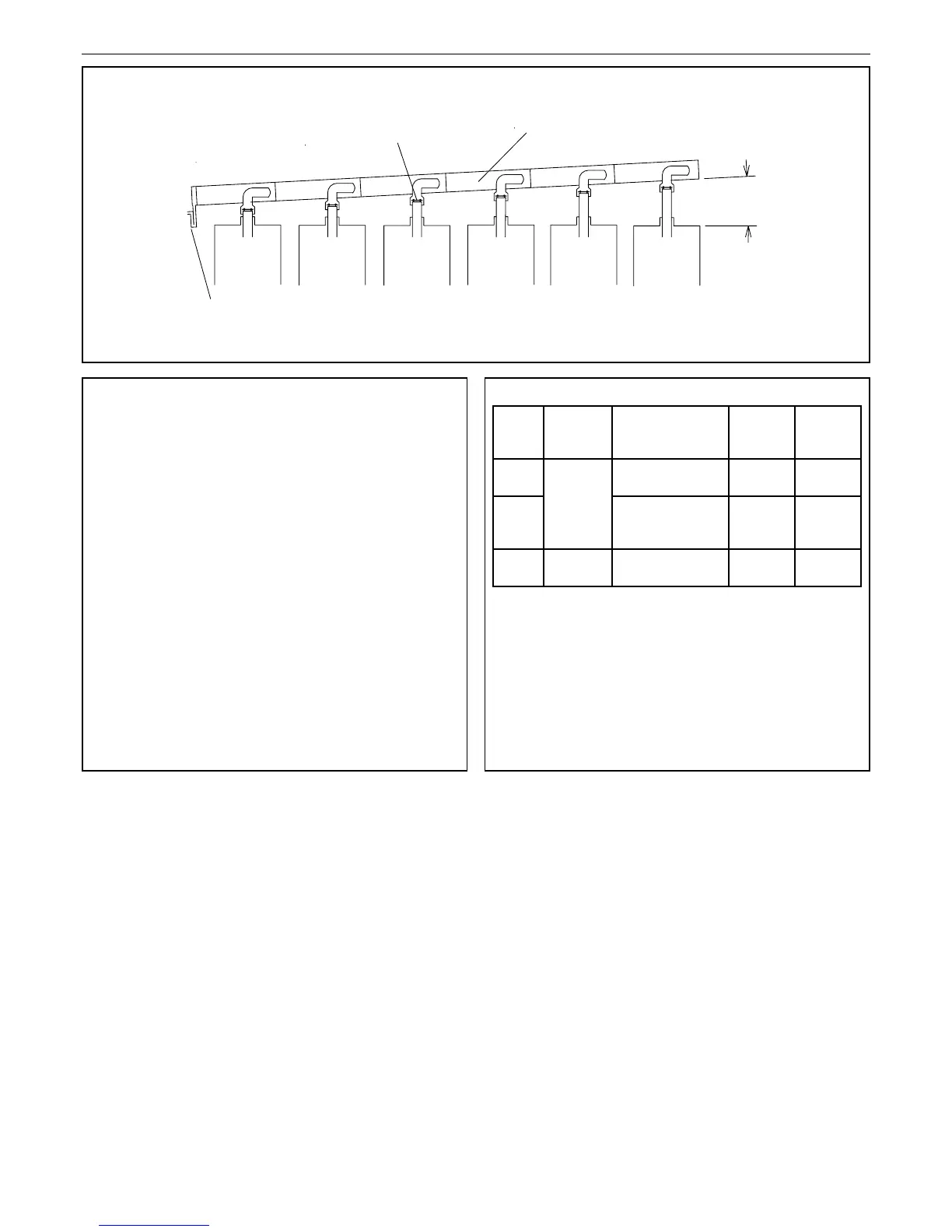

The Cascade Flue system enables Evomax boilers of ‘open

ue’ Type B23 to be connected via a common ue header.

The Cascade Header may be coupled to a bespoke ue outlet

system designed by a ue specialist (section 3).

To ensure safety of operation non-return valves are

incorporated to prevent back-ow of combustion products

through any individual boiler that is not ring.

The condensate produced within the ue drains through the

central trough of the header duct and exits via a siphon.

The maximum permissible system capacity is limited to

the value shown in Table 1.2; this is necessary to ensure

acceptable operation of any individual boiler operating at

its minimum output under the inuence of the total system

pressure generated by the adjacent boilers.

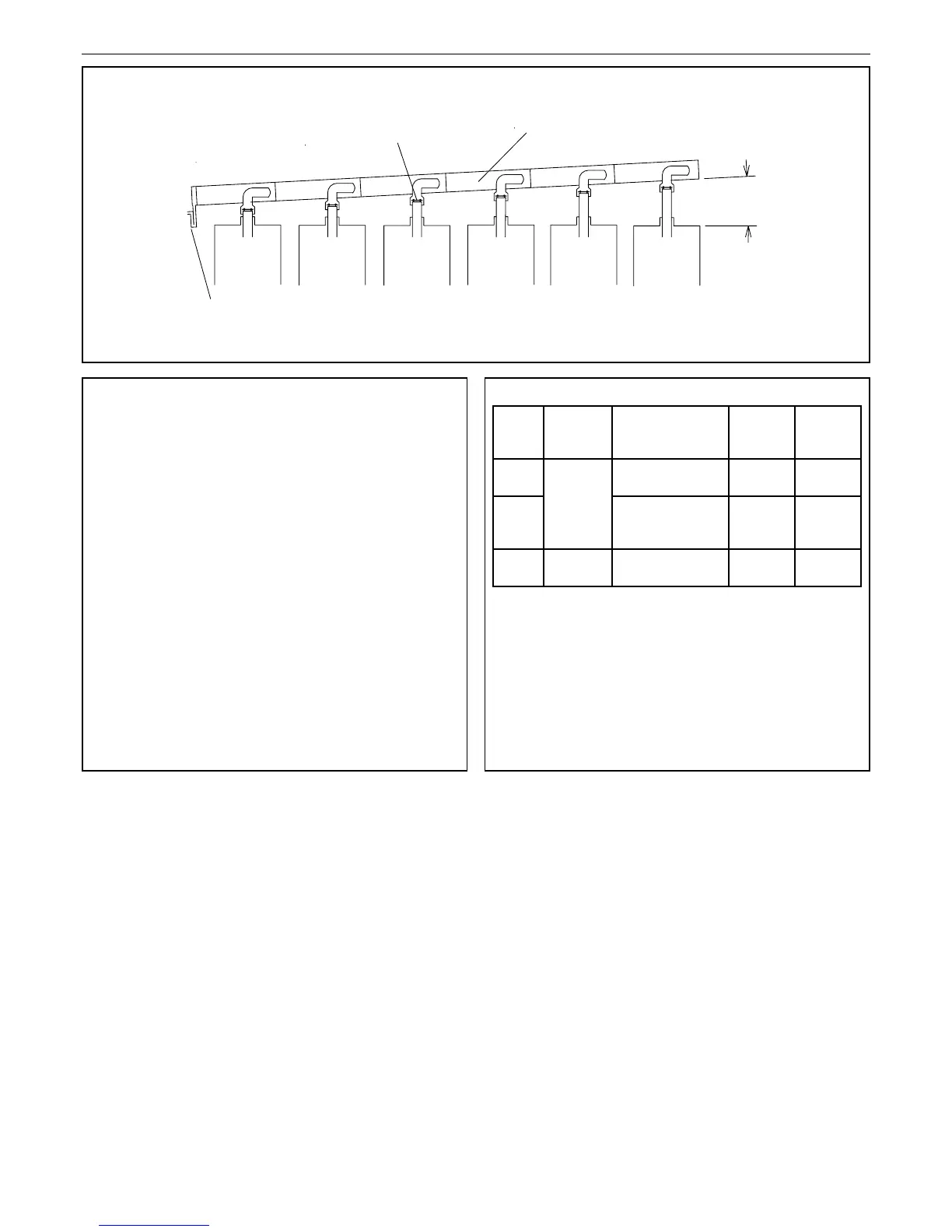

There are optional system congurations that will provide

different characteristics, these options should be considered to

optimise the system performance. (Table 1.2).

1.2 SYSTEM CONFIGURATIONS

Choosing the most appropriate conguration to the required

application will inuence the performance in the following ways;

• System Capacity.

• Number of Boilers

• Turn-Down capability

• Flue length capability

Refer to Section 3.0 for details

Option Gas Type Evomax Models

Max

number

of boilers

Max

System

Capacity

1

Natural

Gas

Combinations of

100,120,150

6 600kW

2

Combinations

that include a

30,40,60 or 80

6 400kW

3 Propane

Combinations of

30P,40P,60P,80P

6 400kW

Non Return Valves

Header

Condensate Drain

(Siphon)

Evomax Cascade Boilers (Type B23)

3.0°

Loading...

Loading...