23

CONNECTIONS & FILLING

IMPORTANT -whenlling:

When lling, there may be a slight water leak from the air vent

therefore electrical connections should be protected.

FILLING

IMPORTANT -whenlling:

A. Ensure the dust cap on air vent located at the rear of the

pump chamber is slightly unscrewed.

B. When lling, there may be a slight water leak from the air

vent therefore electrical connections should be protected.

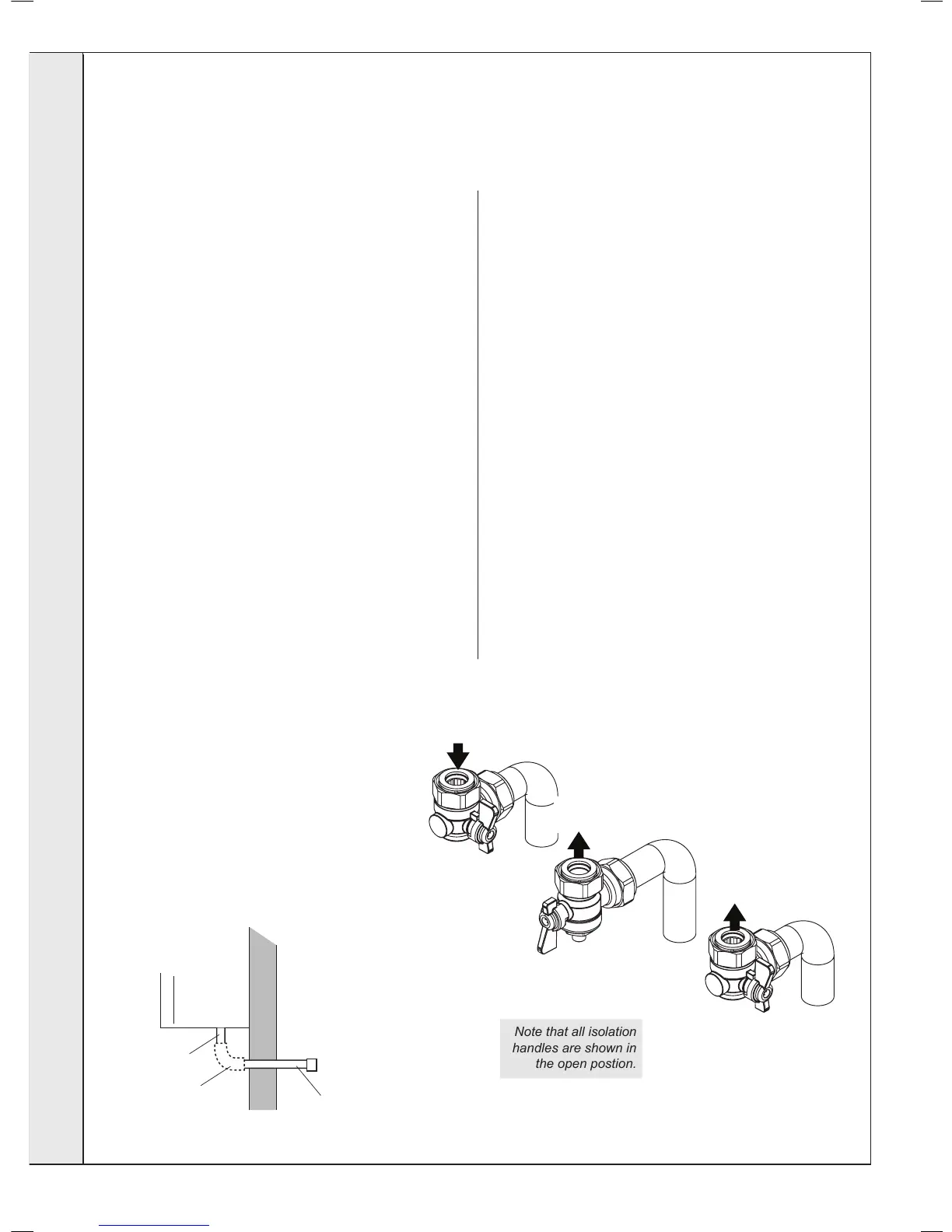

1. Ensure that the CH isolating handles are open.

2. Fill and vent the system. Refer to Frame 2 for lling and

setting pressure procedure.

3. Check for water soundness.

FILLING

NOTES.

Ensure all boss blanking plugs are removed before connecting hardware. Each

valve must be tted to the correct boss as shown in the picture.

Ensure each union is tted with bre seals provided.

Do not subject any of the isolating valves to heat as the seals may be damaged.

WATER CONNECTIONS CH

1. Connect the CH ow service valve and copper tail

provided in the hardware pack to the threaded boss

connection provided at the lower rear of the boiler.

2. Connect the CH rtn. valve (black handle) and copper tail.

3. If connecting the boiler to heating loads in excess of

17.6kW (60,000 Btu/h), connecting ow and return heating

systems pipework must be sized in 28mm diameter at the

point of pipe connection to the boiler tails. use 22mm x

28mm pipe adaptors as appropriate.

GAS CONNECTION

IMPORTANT. The gas service cock is sealed with a non-metallic

blue bre washer, which must not be overheated when making

capillary connections. Refer to Frame 1 for details of the position

of the gas connection.

For additional gas supply info refer to “Gas Supply” on page 8.

PRESSURE RELIEF VALVE DRAIN

The pressure relief valve connection, located at the bottom right-

hand side of the boiler, comprises a 15mm diameter stub pipe.

The Installer to provide a compression joint on the end of the

stub pipe. This assists with pipe removal when servicing.

The discharge pipe should be positioned so that the discharge

of water or steam cannot create a hazard to the occupants of

the premises or damage the electrical components and wiring.

Loading...

Loading...