GB

7 - BAR FEEDER MAINTENANCE KID 70

7 - Pag. 2 / 4

7.1 PRELIMINARY NOTE ON MAINTENANCE

INFORMATION:

Before carrying out any maintenance, start all safety devices provided and

check if it is necessary to inform the staff operating around and people close to

the area. In particular, it is recommended to adequately signal the adjacent

areas and to prevent anyone from approaching all the devices that, if started,

could cause unexpected damages and harm to people.

7.2 SCHEDULED MAINTENANCE

INFORAMATION:

keep the bar feeder in conditions of maximum efficiency, carrying out the

programmed maintenance operations provided by the manufacturer. A good

maintenance will allow the best performances, a longer service life as well as a

constant keeping of safety requirements.

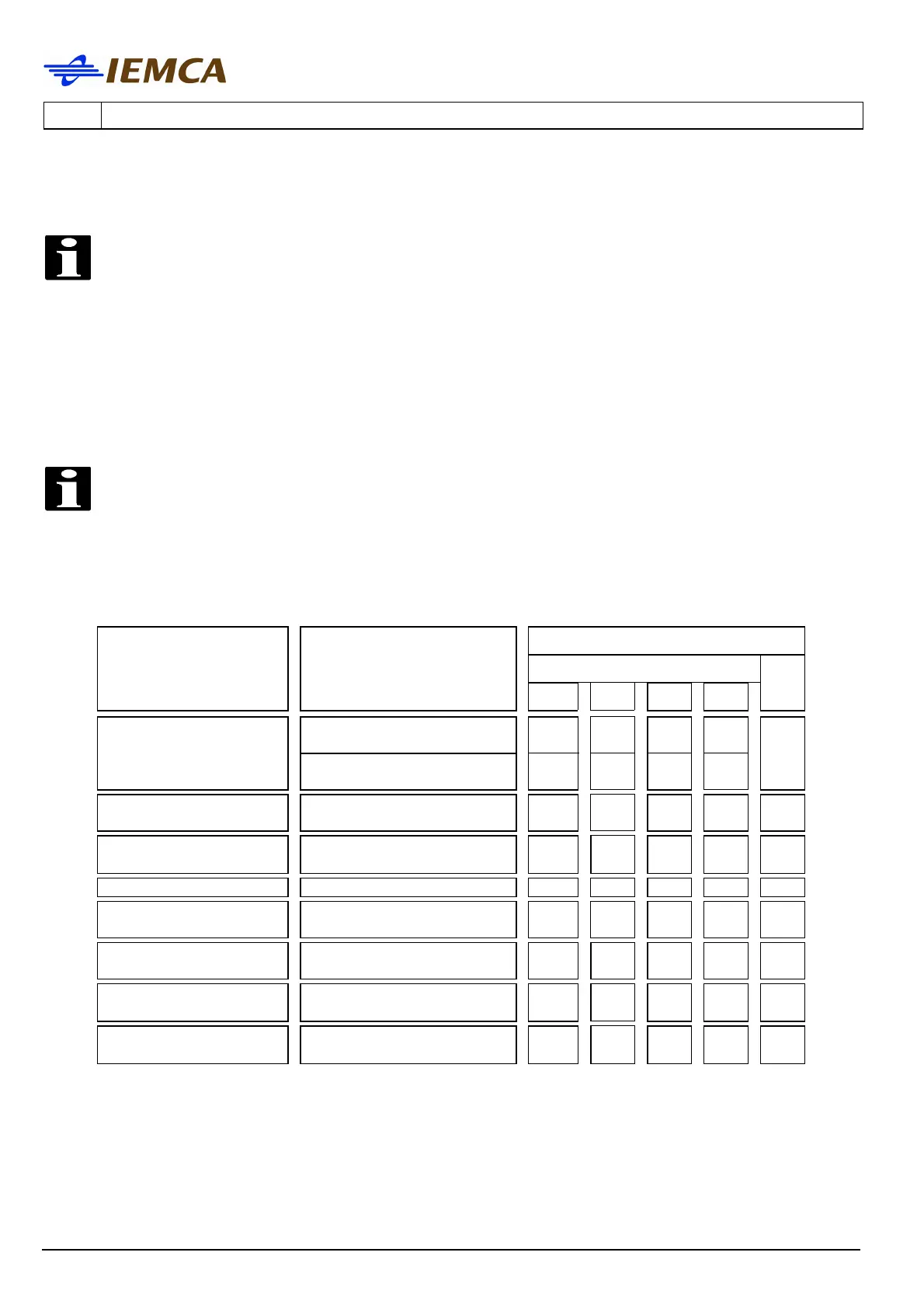

Frequency

Hours

Component Kind of intervention

200 500 1250 2500

Yea

rly

Check and possibly adjust

tension (section 5.5.) •

Feed belt

Test wear. If necessary replace

it (section 9.3.)

•

Fixed tip Test wear. If necessary replace

it (sec.9.2.).

•

Carriage unit

Lubricate the sliding guides

(section 7.4.)

•

Rack Lubricate (section 7.4.) •

Magazine Lubricate the bevel gear pair

(section 7.4.)

•

Stop device Lubricate forks and pins

(section 7.4.)

•

Bar-pushing unit

Lubricate the lifting toothed

wheels (section 7.4.). •

PLC

Replace battery (section 9.4.) •

Loading...

Loading...