INSTALLER

USER

TECHNICIAN

24

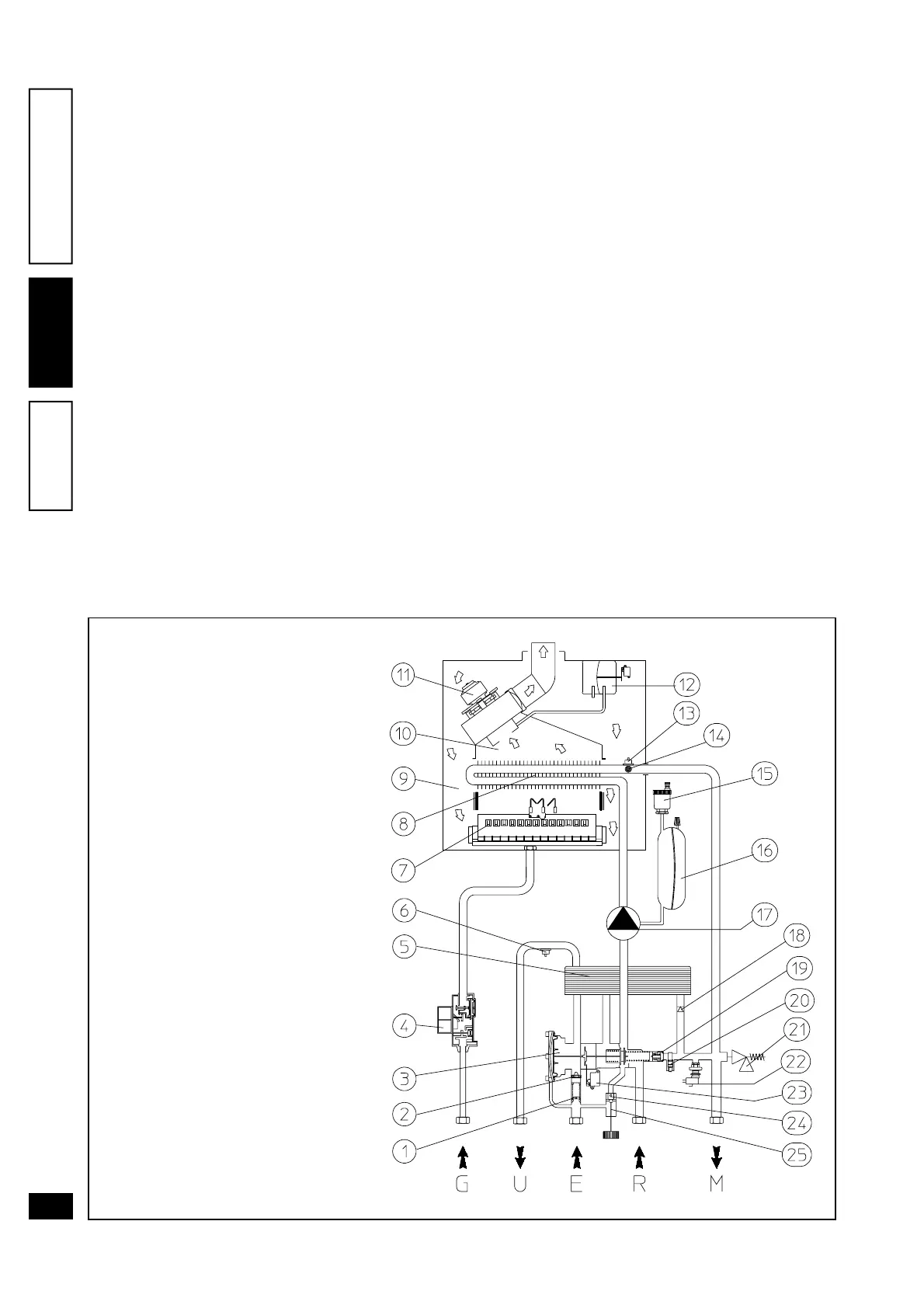

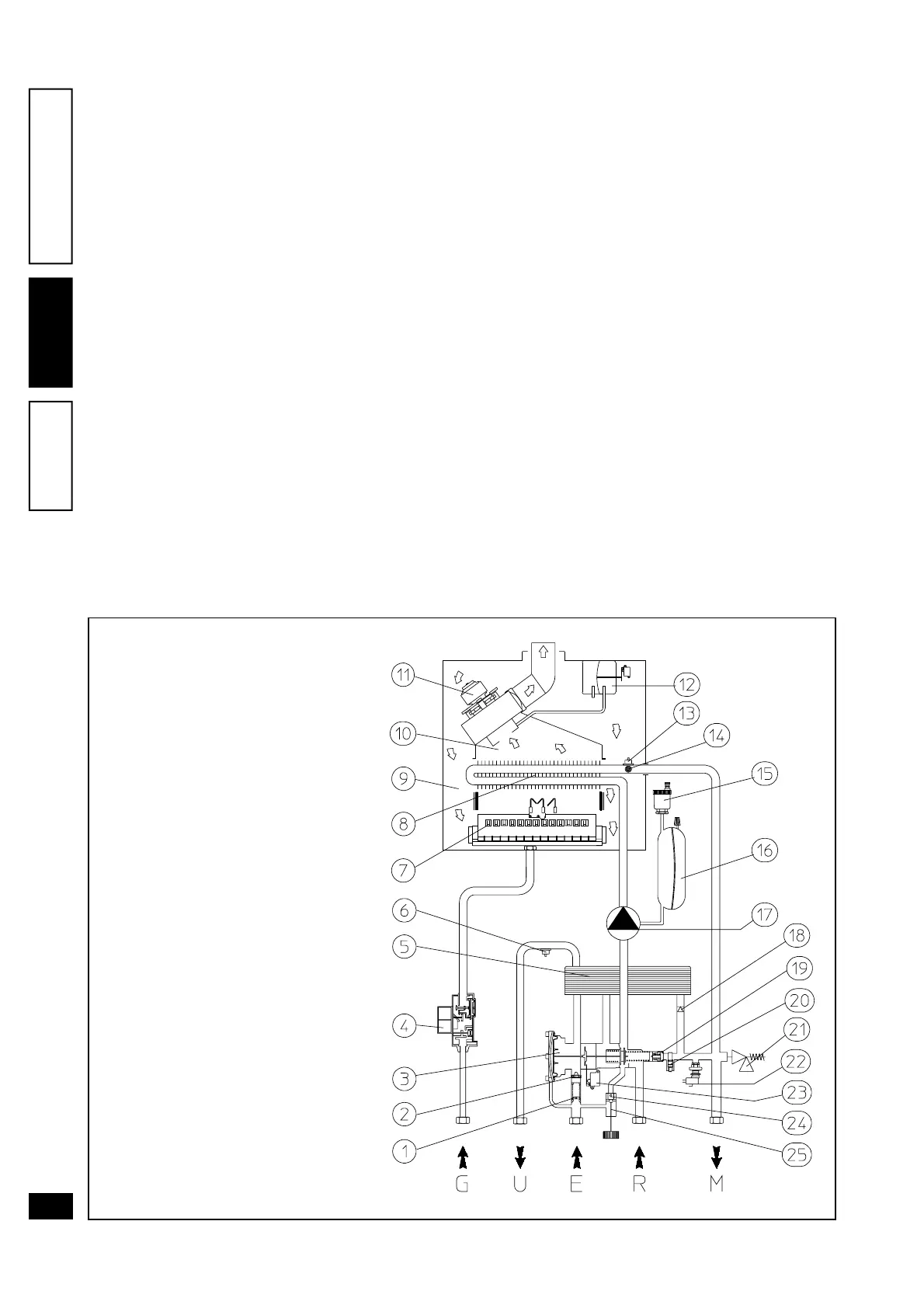

3.1 Eolo Maior @ hydraulic circuit diagram.

3

BOILER START-UP

(PRELIMINARY TESTING)

To start up the boiler, proceed as follows:

- ensure that the declaration of conformity of instal-

lation is supplied with the appliance;

- ensure sealing efficiency of the gas intake circuit

with the shutoff valves closed and then with the

valves open and the gas valve deactivated

(closed); the meter must not indicate gas transfer

for at least ten minutes;

- ensure that the gas used corresponds to specifi-

cations for the boiler;

- ensure connection to a 30V-50Hz power mains,

correct L-N polarity and the earthing connection;

- verify if heating system is water filled, checking that

manometer pointer indicate 1÷1,2 bar of pressure;

- verify if automatic air vent cap is open and that

heating system is well degasified;

- switch on the boiler and ensure correct ignition;

- ensure that the maximum, intermediate and mini-

mum gas flow rate and relative pressure values

conform to specifications in the booklet on page

30-31;

- ensure activation of the safety device in the event

of gas supply failure, as well as the relative activa-

tion time;

- ensure activation of the main switch downstream

of the boiler and inside the boiler;

- check that the intake and/or exhaust terminals are

not blocked;

- ensure activation of the safety pressure switch in

the event of air supply failure;

- ensure activation of all regulation devices;

- seal the gas flow rate regulation devices (if set-

tings are modified);

- ensure production of hot domestic water;

- ensure sealing efficiency of water circuits.

- ensure adequate ventilation and/or aeration of the

boiler environment.

If any checks/inspection give negative results, do not

start the boiler.

Key:

1 - Sanitary min. flow shutter

2 - Flow limiter

3 - 3 way hydraulic valve

4 - Gas valve

5 - Sanitary heat exchanger

6 - Sanitary NTC sensor sensor

7 - Main burner

8 - Primary heat exchanger

9 - Sealed chamber

10 - Flue hood

11 - Flue extraction fan

12 - Fan safety pressure switch

13 - Central heating NTC sensor

14 - Over heat safety thermostat

15 - Automatic air vent valve

16 - Expansion vessel

17 - Circulating pump

18 - One-way valve

19 - Automatic by-pass

20 - Automatic by-pass exclusion stem

21 - 3 bar safety valve

22 - Water pressure switch

23 - Sanitary micro switch

24 - Filling group

G - Gas supply

U - Hot domestic water outlet

E - Domestic water inlet

R - System return

M - System delivery

Loading...

Loading...