TECHNICIAN

INSTALLER

USER

29

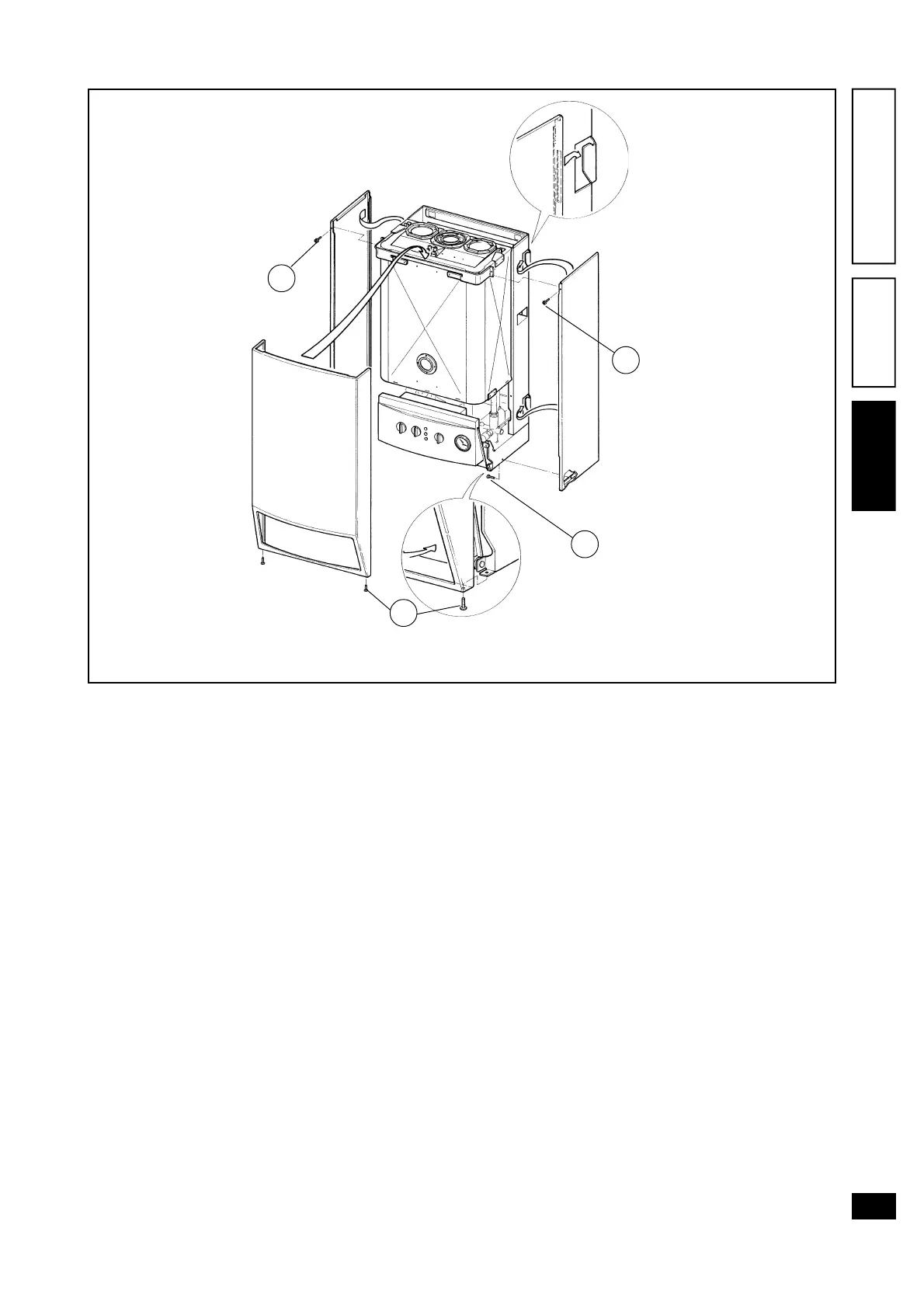

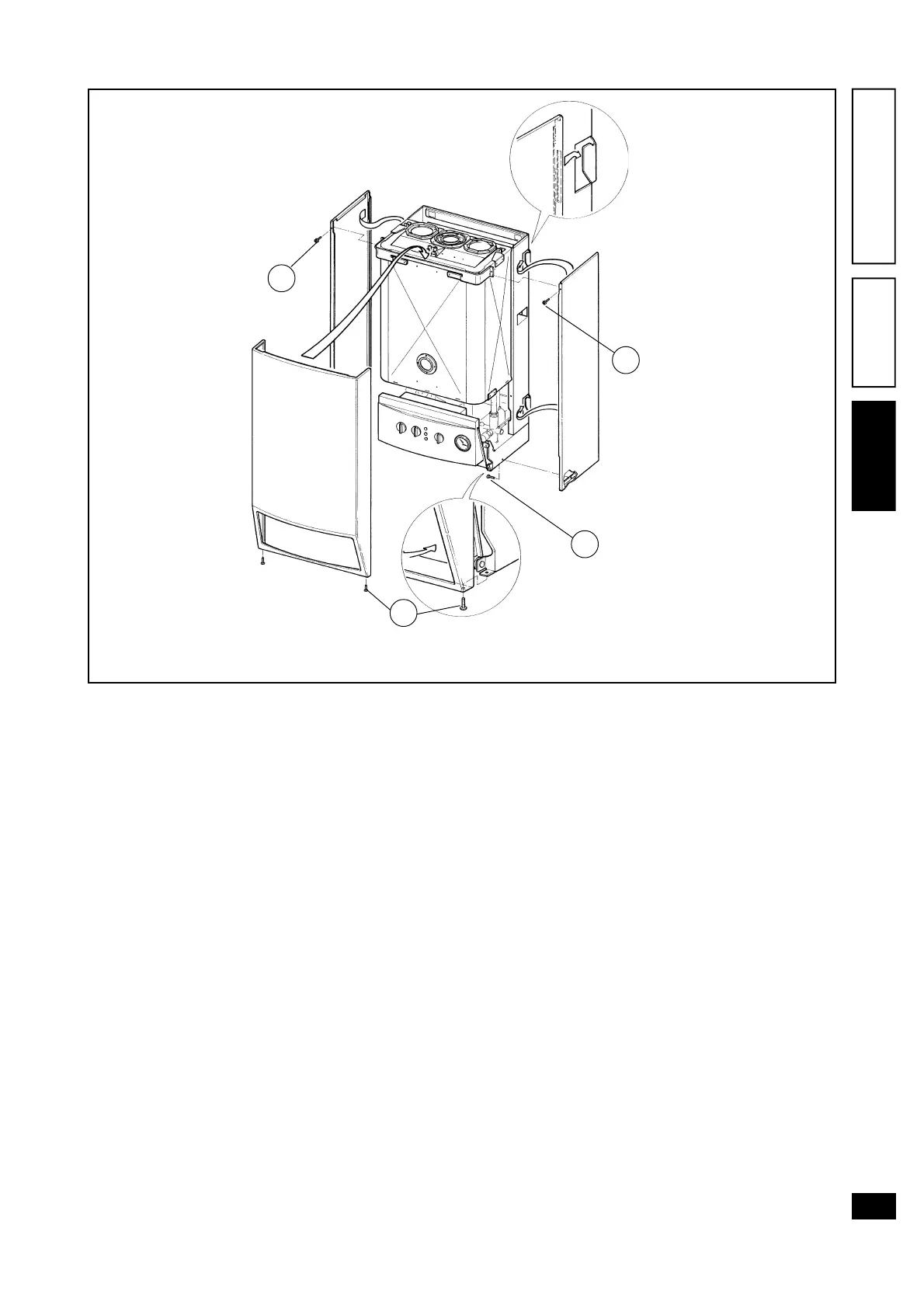

3.12 Annual appliance maintenance.

The following checks and maintenance should be

performed at least once a year.

- Clean the flue side of the heat exchanger.

- Clean the main burner.

- Make a visual inspection of the flue extraction hood

for wear or corrosion.

- Ensure correct ignition and operation.

- Ensure correct settings of the burner in domestic

water and heating phases.

- Verify correct operation and adjustments of the ap-

pliance, in particular:

- activation of the electrical main switch on the

boiler;

- activation of the system control thermostat;

- activation of the domestic water control thermo-

stat.

- Ensure sealing efficiency of the gas intake circuit;

insert a “U” or digital type pressure gauge in the

pressure socket upstream of the gas valve and sub-

sequently closing the boiler shutoff valve (cock) and

closing the gas valve, no pressure variation must

occur in the next five minutes on the gauge.

- Ensure activation of the device for protection

2

2

3

1

against the ionisation flame control gas; activa-

tion time must be less than ten seconds.

- Visually inspect to check for leakage of water or

oxidation of relative couplings.

- Check visually that the water safety drain valve is

not blocked.

- Check that the charge of the expansion vessel af-

ter discharging system pressure to the zero set-

ting (check via boiler pressure gauge), is at 1,0

bar.

- Check that the system static pressure (in cold con-

ditions and after system recharging via the filling

valve ) is between 1 and 1,2 bar.

- Check visually that the safety and control devices

have not been tampered with and/or shorted, in

particular:

- temperature safety thermostat;

- c.h.water switch;

- air pressure switch.

- Ensure correct maintenance and condition of the

electrical installation with particular reference to:

- electrical cables must be inside the channels;

- no traces of black marking or burns.

Loading...

Loading...