1-11

1-10

1-13

1-14

1-12

1-9

7 - IE

INSTALLATORUSERTECHNICIAN

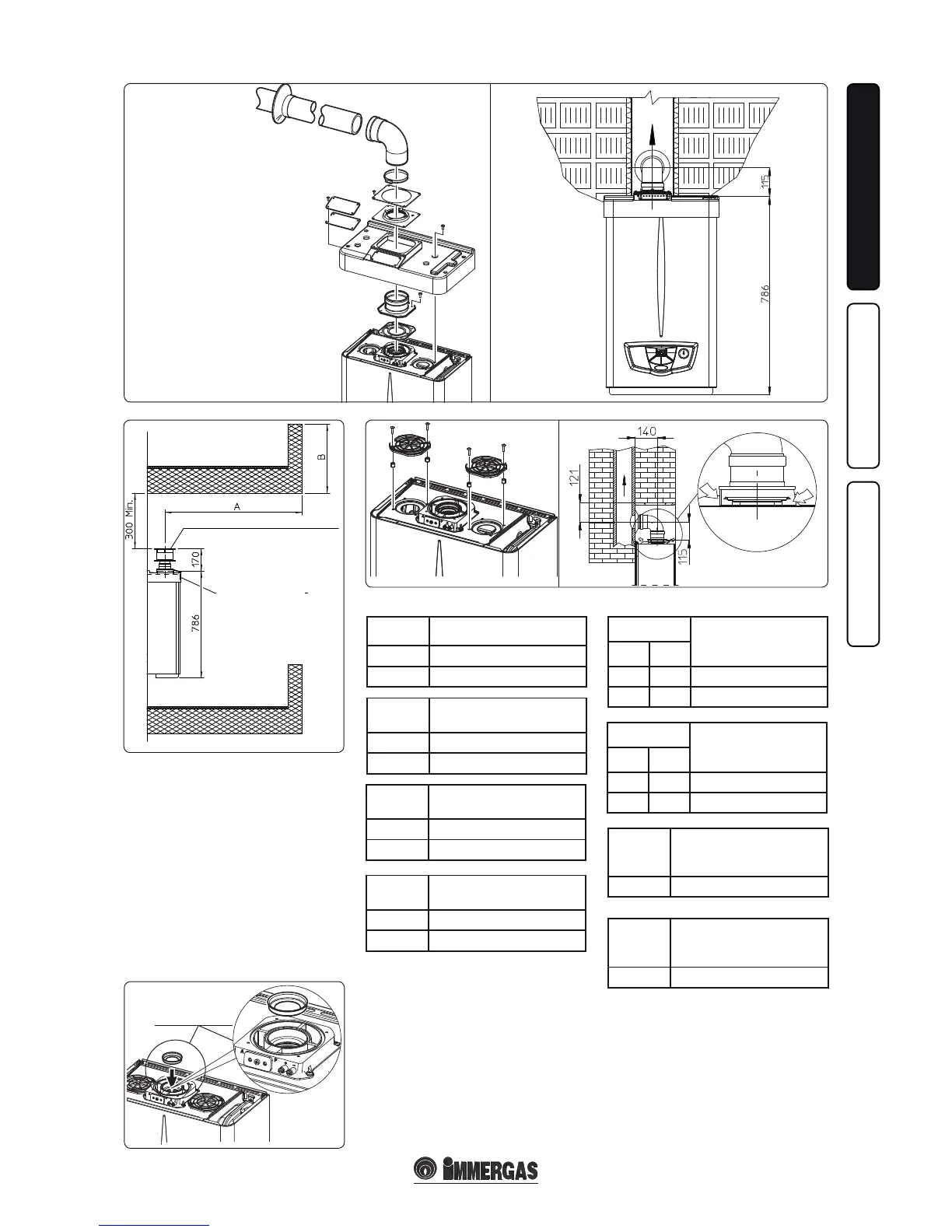

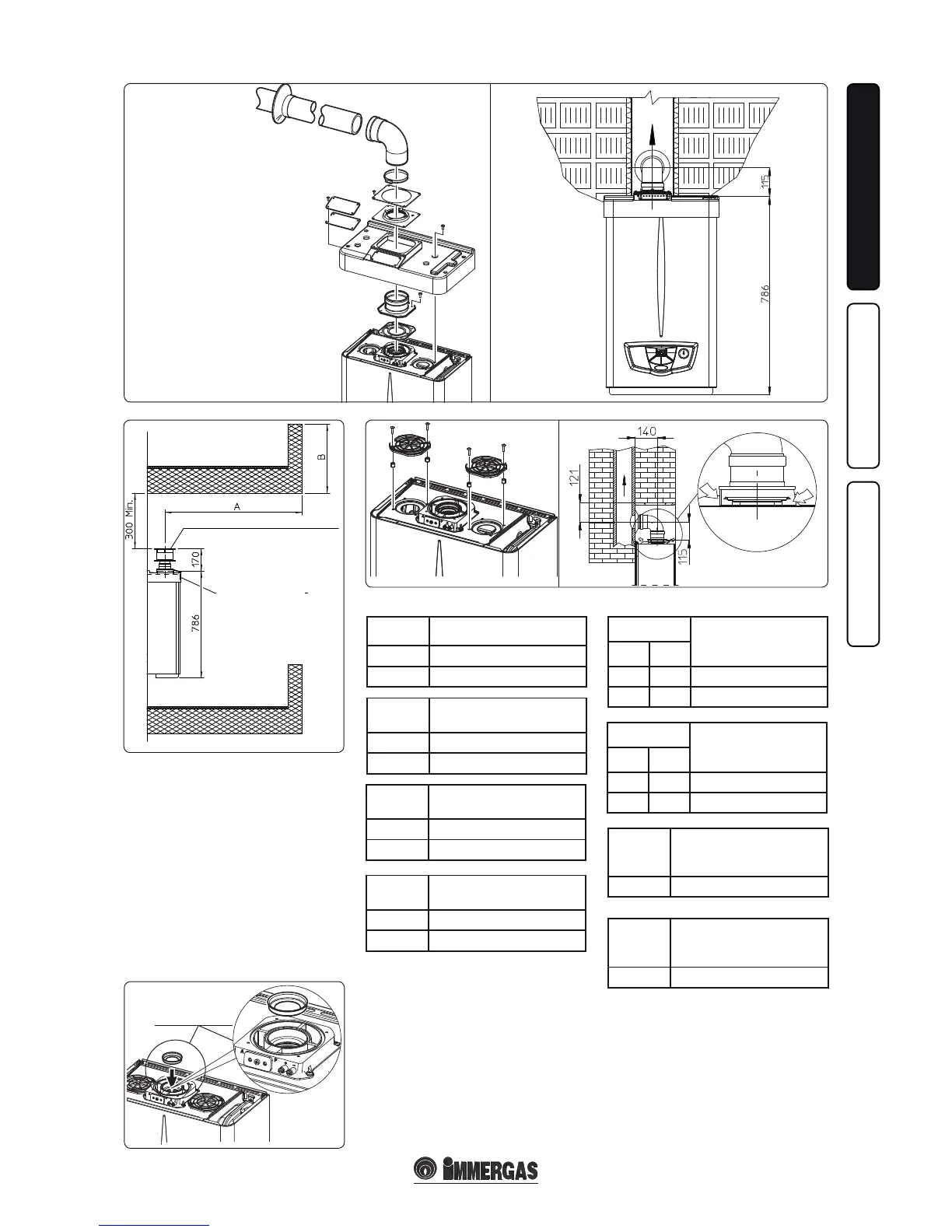

Diaphragm installation. For correct functio-

ning of the boiler it is necessary to install a dia-

phragm on the outlet of the sealed chamber and

before the intake and exhaust pipe (Fig. 1-14).

e choice of suitable diaphragm takes place on

the basis of the type of pipe and its maximum

extension: this calculation can be carried out

using the following tables:

N.B.: the diaphragms are supplied together with

the boiler.

VERTICAL TERMINAL KIT FOR DIRECT DRAINING

INTAKE COVER KIT

DIAPHRAGM

Diaphragm

Extension in meters

pipe Ø 60/100 horizontal

Ø 38 From 0 to 1

Ø 42.5 Exceeding 1

Diaphragm

Pipe extension in metres Ø

60/100 vertical

Ø 38 From 0 to 3.2

Ø 42.5 Exceeding 3.2

Diaphragm

Pipe extension in metres Ø

80/125 horizontal

Ø 38 From 0 to 3.3

Ø 42.5 Exceeding 3.3

Diaphragm

Pipe extension in metres Ø

80/125 vertical

Ø 38 From 0 to 8.1

Ø 42.5 Exceeding 8.1

Diaphragm

*Extension in metres

vertical pipe Ø 80

without bends

exhaust intake

- Ø 45 From 0 to 18

Ø 42.5 - From 14 to 40

Diaphragm

*Extension in metres

horizontal pipe Ø 80

with two bends

exhaust intake

- Ø 45 From 0 to 14

Ø 42.5 - From 14 to 35

Diaphragm

intake

**Extension in metres

horizontal pipe Ø 80 with

two bends

Ø 45 From 0 to 27

Diaphragm

intake

**Extension in metres

vertical pipe Ø 80

without bends

Ø 45 From 0 to 27

* ese maximum extension values are considered

intake with 1 metre drain pipe.

** ese maximum extension values are considered

exhaust with 1 metre intake pipe.

Loading...

Loading...