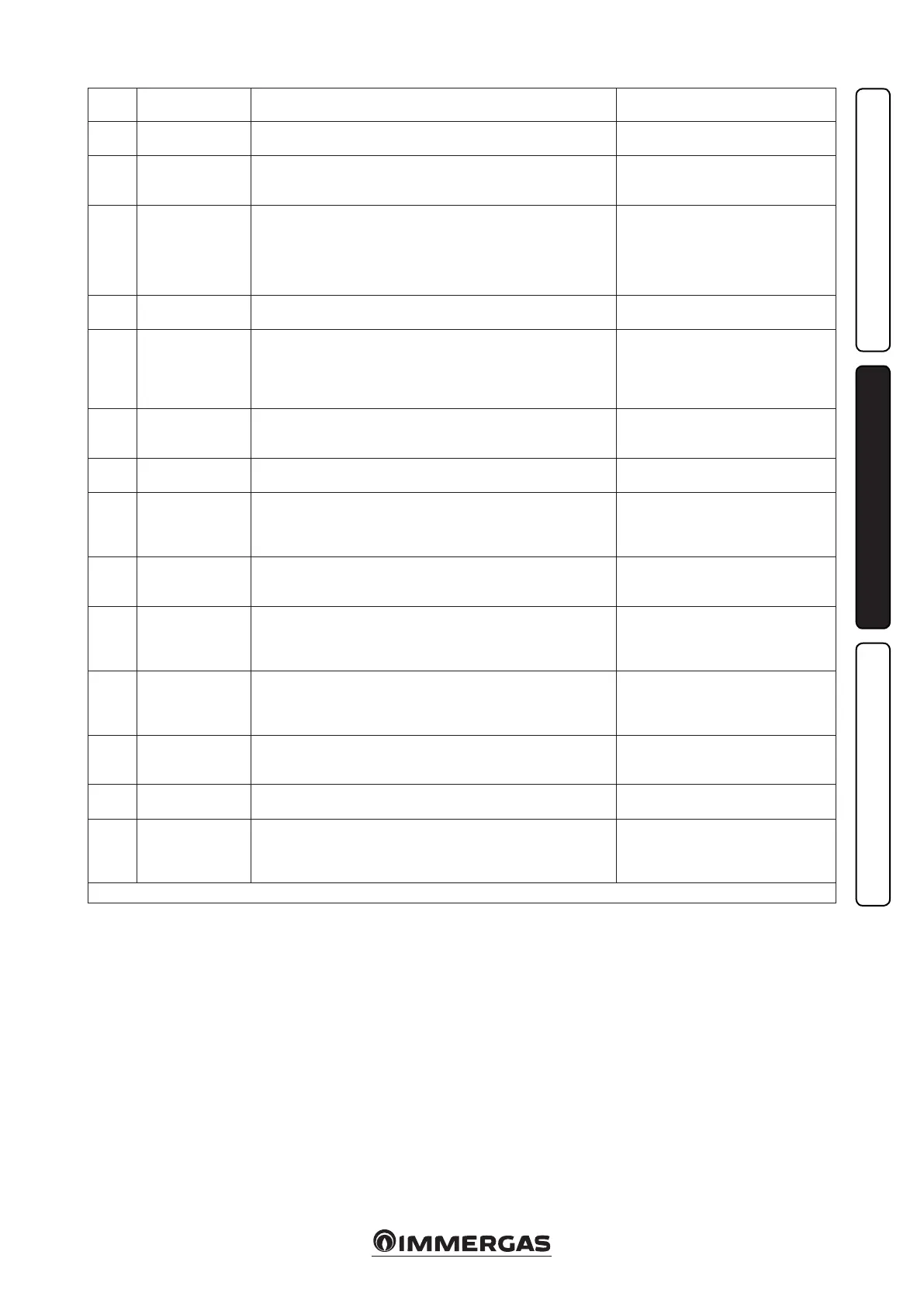

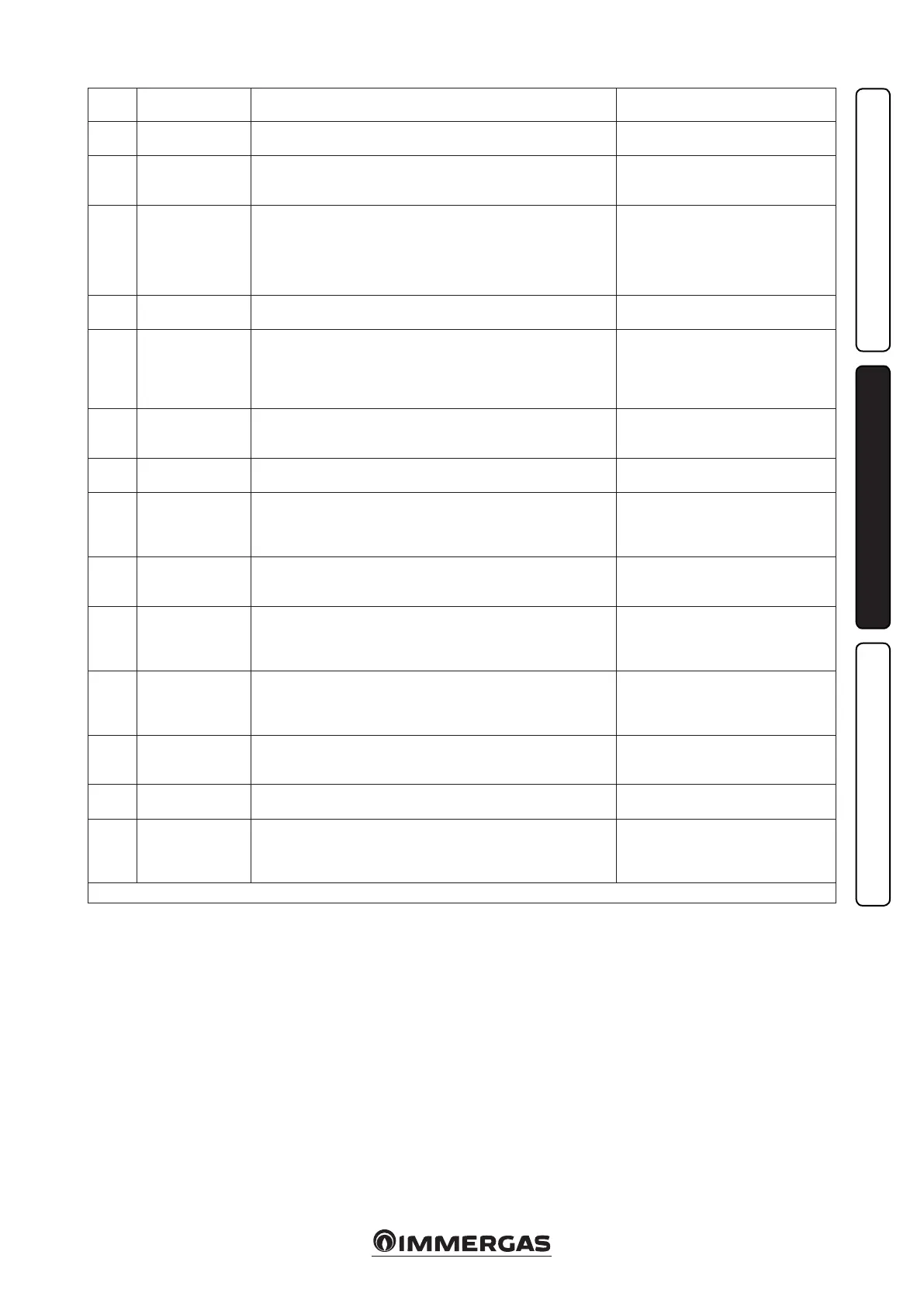

13

INSTALLERUSER

MAINTENANCE TECHNICIAN

Error

Code

Anomaly signalled Cause Boiler status / Solution

24

Push button control

panel anomaly

e board detects an anomaly on the pushbutton panel

If normal conditions are restored the boiler

restarts without having to be reset (1).

25

Block due to ue gas

temperature gradi-

ent intervention

If the board detects a rapid increase in ue gas temperature probably due

to a blocked circulating pump or lack of water in the heat exchanger, the

boiler shuts down due to the ue gas temperature gradient trip.

Press the Reset button (1).

27

Insucient circula-

tion

is occurs if there is overheating in the boiler due to insucient water

circulating in the primary circuit; the causes can be:

- low system circulation; check that no shut-o devices are closed on the

heating circuit and that the system is free of air (deaerated);

- pump blocked; free the pump.

Press the Reset button (1).

29 Flue probe anomaly

If the board detects an anomaly on the ue gas probe the boiler will not

start

e boiler does not start (1).

31

Loss of remote con-

trol communication

is occurs 1 minute aer communication is lost between the boiler and

the remote control.

Power cycle the boiler. If the Remote

Control is still not detected on re-starting

the boiler will switch to local operating

mode, i.e. using the controls on the control

panel (1).

36

IMG Bus communi-

cation loss

Communication between the various components is interrupted due to

an anomaly on the boiler control unit, on the zone control unit or on

the IMG Bus.

e boiler does not satisfy the room heating

requests (1).

37

Low power supply

voltage

is occurs when the power supply voltage is lower than the allowed limits

for the correct boiler operation.

If normal conditions are restored the boiler

restarts without having to be reset (1).

38 Loss of ame signal

is occurs when the boiler is ignited correctly and the burner ame

switches o unexpectedly; a new ignition attempt is performed and if

normal conditions are restored, the boiler does not need to be reset (this

fault can be checked in the list of errors in the “Information” menu only).

If normal conditions are restored the boiler

restarts without having to be reset (1).

43

Block due to loss

of continue flame

signal

is occurs if the ''Flame signal loss'' error occurs many times in a row

within a preset period (38).

Press the Reset button, before restarting, the

boiler will run a post-ventilation cycle (1).

44

Block for exceeding

the maximum accu-

mulated time, close

gas valve opening

is occurs if the gas valve remains open for longer than required for

normal operation, without the boiler switching on.

Press the Reset button (1).

45 High T

If the board detects a sudden and unexpected rise in ΔT between the

system ow probe and return probe, the boiler limits the burner output

to prevent damaging the condensing module; when the correct ΔT has

been restored, the boiler returns to normal operation.

Make sure there is water circulating in the

boiler, that the pump is congured accord-

ing to system requirements and that the

return probe works properly (1).

46

Low temperature

safety thermostat

(optional)

During normal operation, if an anomaly causes excessive overheating of

the ow temperature in low temperature conditions, the boiler blocks.

In this case, aer suitable cooling, it is pos-

sible to reset the thermostat (see relative

instructions sheet) (1).

47

Burner power limi-

tation

Should ue high temperature be detected, the boiler reduces power sup-

plied so as not to damage it.

(1).

49

High temperature

block on return

probe

is occurs when the heat exchanger return circuit reaches too high of

a temperature.

Make sure that water circulates properly

in the boiler and that the three-way valve

works properly. To eliminate it, the Reset

button (C) must be pressed (1).

(1) If the shutdown or fault persists, contact an authorised company (e.g. Authorised Technical Aer-Sales Service).

Loading...

Loading...