5

1-3

INSTALLERUSER

MAINTENANCE TECHNICIAN

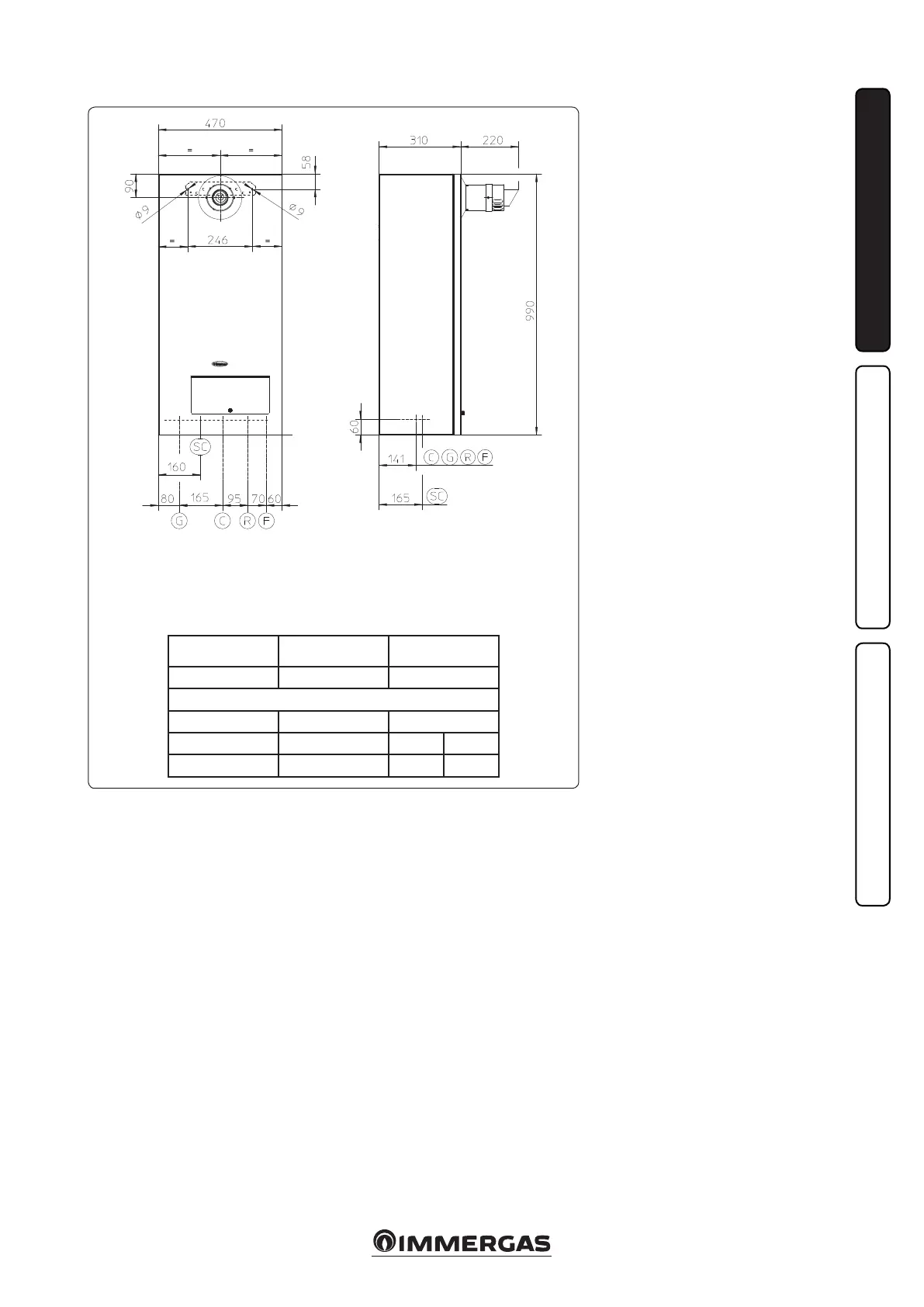

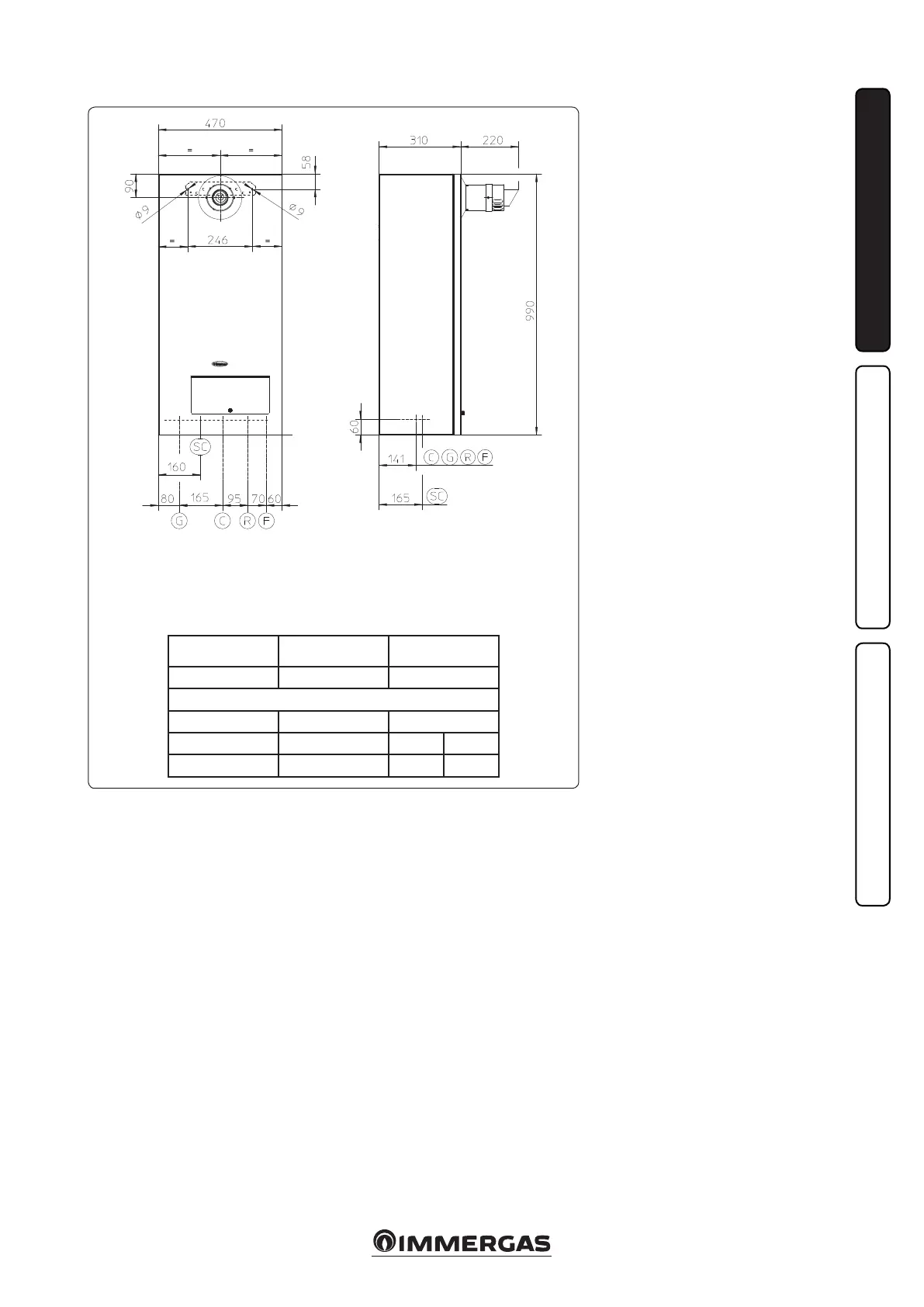

1.2 MAIN DIMENSIONS.

minimum temperature required for preserving

the system.

The boilers is made from materials that are

resistant to ethylene and propylene glycol-based

anti-freeze liquids.

For life and possible disposal, follow the

supplier's instructions.

- Protect the condensate drain trap and circuit

board against freezing by using an accessory

that is supplied on request (anti-freeze kit)

comprising two electric heating elements,

the relevant cables and a control thermostat

(carefully read the installation instructions

contained in the accessory kit pack).

Boiler anti-freeze protection is thus ensured only if:

- the boiler is correctly connected to gas and

electricity power supply circuits and powered;

- the anti-freezing kit components are ecient.

In these conditions the boiler is protected against

freezing to temperature of -15°C.

e warranty does not cover damage due to inter-

ruption of the electrical power supply and failure

to comply with that stated on the previous page.

N.B.: if the boiler is installed in places where the

temperature falls below 0°C the domestic water

and heating attachment pipes must be insulated.

1.4 CONNECTIONS.

Gas connection.

Our boilers are designed to operate with NG

and Universal LPG. Supply pipes must be sized

correctly to relevant gas codes.

Before connecting the gas line, carefully clean

inside all the supply pipes to remove any residue

that could impair boiler eciency. Also make

sure the gas corresponds to that for which

the boiler is prepared (see boiler data-plate).

If dierent, the appliance must be converted

for operation with the other type of gas (see

converting appliance for other gas types). e

dynamic gas supply (NG or Universal LPG)

pressure must also be checked according to

the type used in the boiler, which must be in

compliance, as insufficient levels can reduce

boiler output and cause malfunctions.

Ensure correct gas isolation valves connection.

e gas supply pipe must be suitably dimensioned

according to current regulations in order to

guarantee correct gas flow to the burner in

conditions of maximum boiler.

N.B.: there is a special adhesive label inside the

built-in frame displaying the layout of the boiler

connections.

Fuel gas quality. The appliance has been

designed to operate with gas free of impurities;

otherwise it is advisable to fit special filters

upstream from the appliance to restore the

purity of the gas.

Cold Water connection.

Attention: Filling the system, Hunt Heating

recommends the use of Auto fill valves sold

as an optional extra. Once satisfactory system

pressure is achieved, Auto ll valve MUST BE

TURNED OFF.

Attention: in order not to void the warranty

before making the boiler connections, carefully

clean the heating system on the primary heat

exchanger (pipes, radiators, etc.) with special

cleaning products (Fernox) to remove any

deposits that could compromise correct boiler

operation.

Chemical treatment of the heating system water

is required, in compliance with the technical

standards in force, in order to protect the system

and the appliance from deposits (e.g., lime scale),

slurry or other hazardous deposits. Products like

Fernox are suitable for this appliacation. Use

of backow devices are maditory when using

chemicals/water treatments or alternatively,

ensure physical air break.

Heating Water connections must be made using

approved valves this helps with maintenance and

servicing. Hunt Heating can provide valves as

optional extras.

e boiler safety valve outlet must be connected

to a Tun Dish or Directly to a suitable overow

outlet.

1.3 ANTIFREEZE PROTECTION.

Minimum temperature -5°C. e boiler comes

standard with an anti-freeze function that

activates the pump and burner when the system

water temperature in the boiler falls below 4°C.

e anti-freeze function is only guaranteed if:

- the boiler is correctly connected to gas and

electricity power supply circuits;

- the boiler is powered constantly;

- the boiler is not in no ignition block (Par. 2.5);

- the boiler essential components are not faulty.

In these conditions the boiler is protected against

freezing to an environmental temperature of -5°C.

Minimum temperature -15°C. If the boiler is

installed in a place where the temperature falls

below -5°C and in the event there is no gas, or

the boiler goes into ignition block, the appliance

may freeze.

To prevent the risk of freezing follow the

instructions below:

- Protect the central heating circuit from

freezing by introducing a good quality anti-

freeze liquid (specically for central heating

systems), (Fernox), carefully following the

manufacturer's instructions regarding the

percentage necessary with respect to the

Key:

G - Gas supply (not supplied as standard)

R - Return - CH

F - Flow - CH

SC - Condensate drain (supplied as standard)

(minimum internal diameter Ø13 mm)

C - Cold ll

Height

(mm)

Width

(mm)

Depth

(mm)

990 470 310

CONNECTIONS

CORD INLET GAS SYSTEM

C G R F

1/2” 3/4” 3/4” 3/4”

Loading...

Loading...