9

1-10

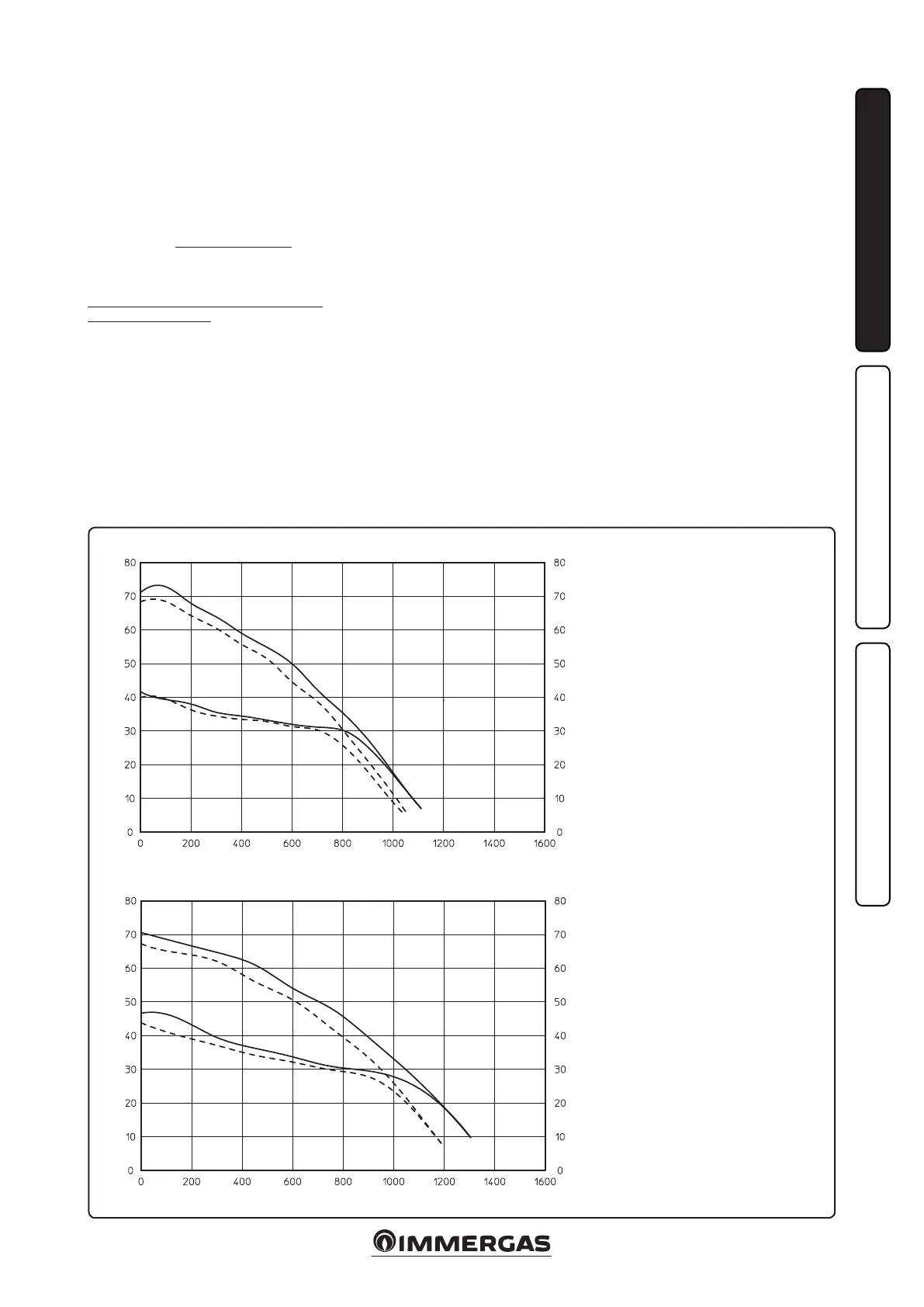

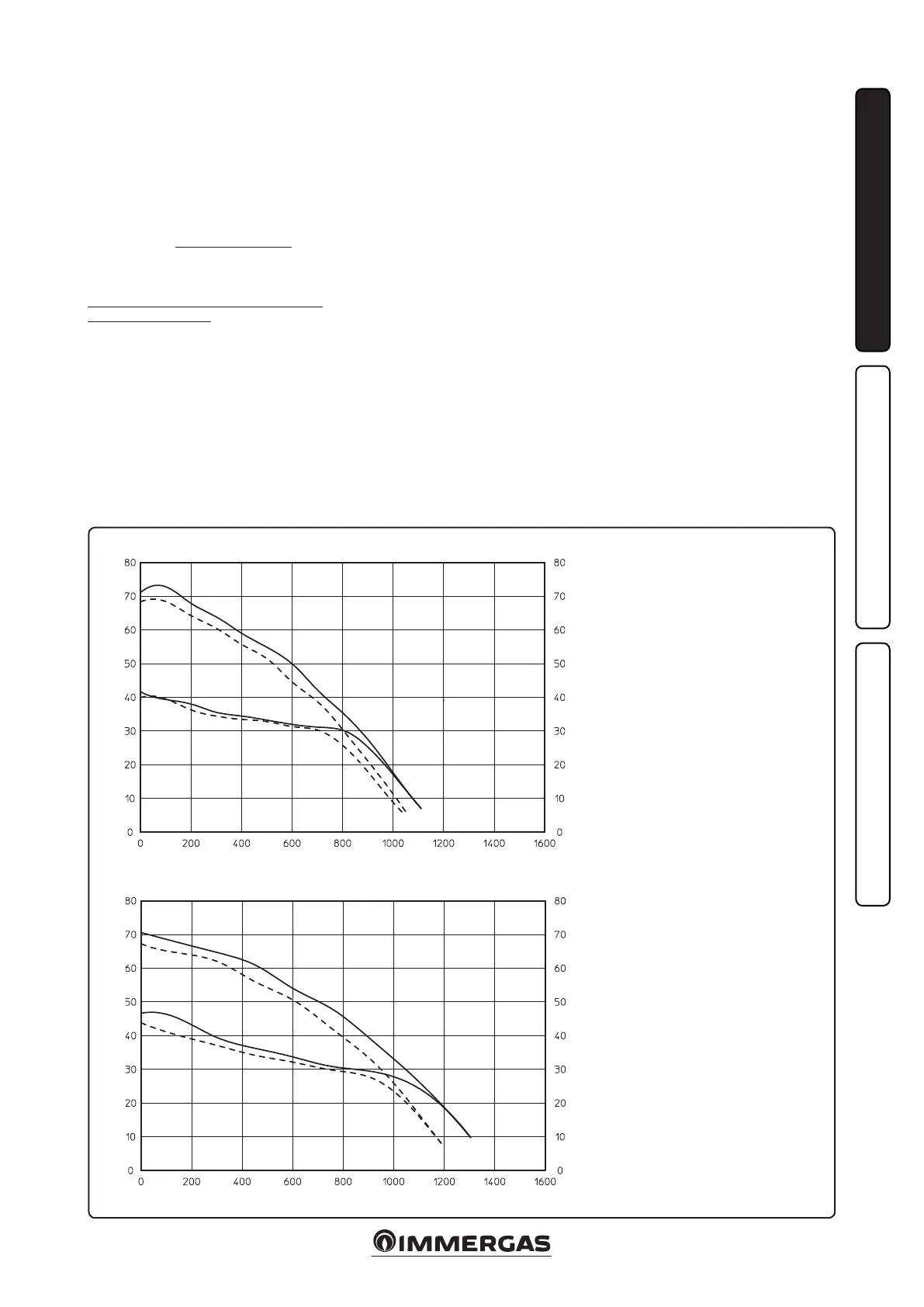

B

C

D

A

B

C

D

A

INSTALLERUSER

MAINTENANCE TECHNICIAN

- check activation of the master switch located

upstream from the boiler and in the boiler;

- check that the intake/exhaust concentric

terminal (if tted) is not blocked.

e boiler must not be started up even if only

one of the checks should be negative.

N.B.: the boiler preliminary check must be carried

out by a qualied technician. e conventional

boiler warranty is valid as of the date of testing if

not commissioned by a qualied technician.

1.12 CIRCULATION PUMP.

e “INTEC 12-30 SYSTEM EXTERNAL” series

boilers are supplied with a built-in circulation

pump with 3-position electric speed control.

e boiler does not operate correctly with the

circulation pump on speed one. To ensure

optimal boiler operation, in the case of new

system it is recommended to use the pump at

maximum speed, position 3.

Pump release. If, aer a prolonged period of

inactivity, the circulation pump is blocked,

unscrew the front cap and turn the motor sha

using a screwdriver. Take great care during this

operation to avoid damage to the motor.

1.9 SYSTEM FILLING.

Once the boiler is connected, proceed with

system lling through the arranged lling valve,

which can be connected to the return pipe system

and as close as possible to the boiler (Fig. 1-11),

or ideally via connection ‘C’.

Filling is performed at low speed to ensure release

of air bubbles in the water via the boiler and

heating system vents.

e boiler has a built-in automatic venting valve

on the circulator. Check if the cap is loose. Open

the radiator air vent valves.

Close radiator vent valves when only water

escapes from them.

Close the lling valve when the boiler manometer

indicates approx. 1.2 bar.

N.B.: during these operations, turn on the cir-

culating pump at intervals by means of the main

selector switch on the control panel. Vent the

circulation pump by loosening the front cap and

keeping the motor running. Only open for a few

seconds at a time.

In presence of the automatic lling, the auto ll

valve must necessarily be isolated aer system

is pressurized.

1.10 GAS SYSTEM STARTUP.

To start up the system, make reference to the

Standard: is divides the systems and therefore

the start-up operations into three categories: new

systems, modied systems, re-activated systems.

In particular, for new gas systems:

- open windows and doors;

- avoid presence of sparks or naked ames;

- bleed all air from pipelines;

- check that the internal system is properly sealed

according to specications.

1.11 BOILER START UP IGNITION.

For first ignition, the following must be

performed:

- check that the internal system is properly sealed

according to specications;

- ensure that the type of gas used corresponds

to boiler settings;

- switch the boiler on and ensure correct

ignition;

- make sure that the gas ow rate and relevant

pressure values comply with those given in the

manual;

- ensure that the safety device is engaged in the

event of gas supply failure and check activation

time;

Flow rate (l/h)

A = Head available to the system at maxi-

mum speed with by-pass closed.

B = Head available to the system at maxi-

mum speed with by-pass open.

C = Head available to the system at second

speed with by-pass closed.

D = Head available to the system at second

speed with by-pass open.

Head (m H

2

O)

Head (kPa)

Head available to the system (INTEC 12).

Head available to the system (INTEC 30).

Flow rate (l/h)

Head (m H

2

O)

Head (kPa)

Loading...

Loading...