19

1-28

19

INSTALLERUSER

MAINTENANCE TECHNICIAN

1.26 CIRCULATION PUMP.

e boilers are supplied with a variable speed

circulator pump.

During the heating stage the Auto and Fixed

operating modes are available.

• Auto (default): Automatic circulator pump

speed and proportional head: e automatic

circulator pump speed varies according to the

power emitted by the burner; the greater the

power, the greater the speed. Moreover, within

the parameter, one can also adjust the circulator

pump operating range by setting the maximum

speed “A3” parameter (adjustable from 5 to 9)

and the “A4” minimum speed parameter (adju-

stable from 5 to the max. set speed).

• Fixed (5 ÷ 9): by setting parameters “A3” and

“A4” at the same value, the pump operates at

constant speed.

N.B.: for the boiler to work properly, it is not

allowed to drop below the minimum value

indicated above.

In domestic hot water mode, the circulator pump

always runs at full speed.

Pump release. If, aer a prolonged period of

inactivity, the circulation pump is blocked, turn

the motor sha using a screwdriver. Take great

care during this operation to avoid damage to

the motor.

By-pass Regulation (part. 26 Fig. 1-29). e

boiler leaves the factory with the by-pass open.

If necessary, the by-pass can be regulated to

system requirements from minimum (by-pass

closed) to maximum (by-pass open). Adjust

using a at head screwdriver, turn clockwise

and open the by-pass, anticlockwise it is closed.

1.27 KITS AVAILABLE ON REQUEST.

• System shut-off valve kits with or without

inspection lter (on request). e boiler is

designed for installation of system interception

cocks to be placed on ow and return pipes

of the connection assembly. is kit is very

useful for maintenance because it allows to

empty just the boiler without having to empty

the entire system. Moreover, the version with

lter preserves the functioning characteristics

of the boiler thanks to its inspectionable lter.

• System zone control unit kit (on request). If

the heating system is to be divided into several

zones (max. three), in order to interlock them

with separate adjustments and to keep water

ow rate high for each zone, Immergas supplies

zone system kits by request.

• Polyphosphate dispenser kit (on request). e

polyphosphate dispenser reduces the formation

of lime-scale and preserves the original heat

exchange and domestic hot water production

conditions. e boiler is prepared for applica-

tion of the polyphosphate dispenser kit.

• Relay board (on request). e boiler is prepared

for the installation of a relay card that allows

to increase the features of the appliance and

therefore functioning possibilities.

• Cover kit (on request). If installed outdoors in a

partially protected place with direct air intake,it

is compulsory to mount the appropriate top

protection cover for the correct functioning

of the boiler and to protect it from adverse

weather conditions.

• Cycloidal lter kit (on request). e magnetic

cycloidal filter is able to detect the ferrous

residues present in the system's water. anks

to the two cocks in the kit, it facilitates main-

tenance by cleaning the lter without having

to empty the circuit.

e above-mentioned kits are supplied complete

with instructions for assembly and use.

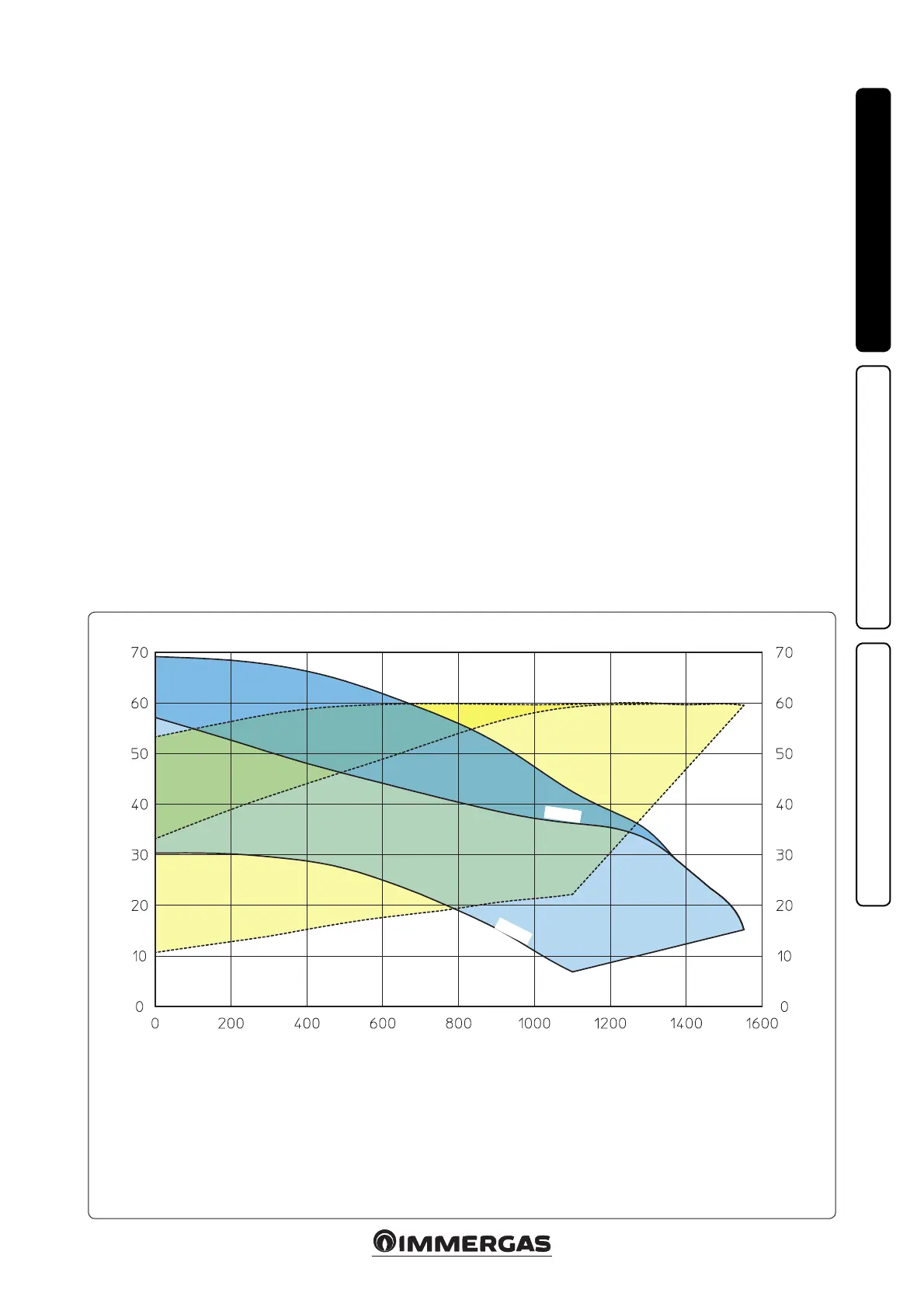

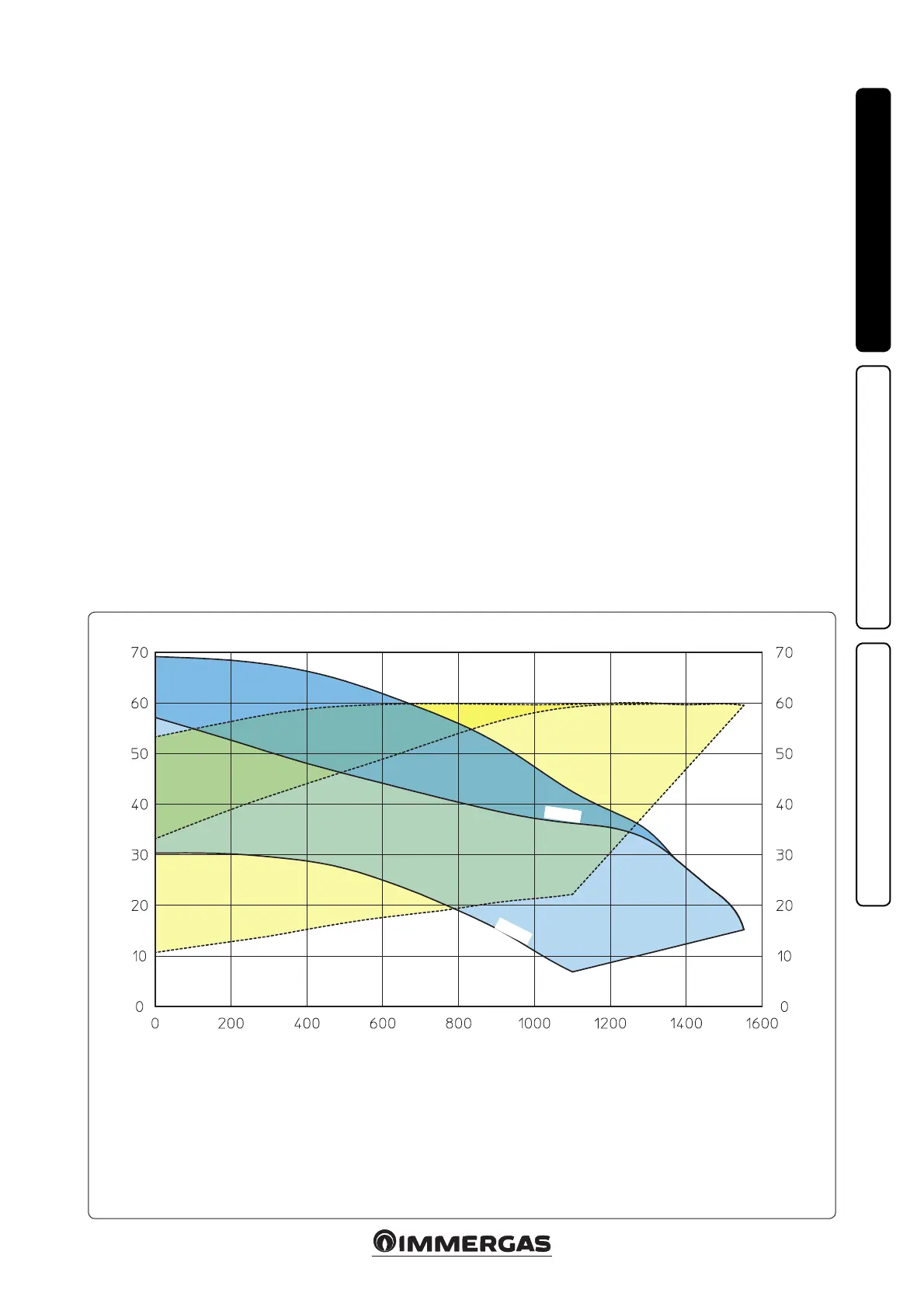

Total head available to the system.

Head (kPa)

A+B = Head available with by-pass closed

B = Head available with by-pass open

C+D = Power absorbed by the pump with by-pass open (dotted area)

D = Power absorbed by the pump with by-pass closed (dotted area)

Circulator pump absorbed power (W)

Flow rate (l/h)

Speed 9

Speed 9

Speed 5

Loading...

Loading...