2525

INSTALLERUSER

MAINTENANCE TECHNICIAN

2.7 BOILER SHUTDOWN

Switch the boiler o by putting it in “o” mode,

disconnect the onmipolar switch outside of the

boiler and close the gas cock upstream from the

appliance. Never leave the boiler switched on if

le unused for prolonged periods.

2.8 RESTORING CENTRAL HEATING

SYSTEM PRESSURE.

Periodically check the system water pressure.

e boiler pressure gauge should read a pressure

between 1 and 1.2 bar.

If the pressure falls below 1 bar (with the circuit

cold) restore normal pressure via the valve located

at the bottom of the boiler (Fig. 1-3).

N.B.: close the cock aer the operation.

If pressure values reach around 3 bar the safety

valve may be activated.

In this case, remove water from an air vent valve

of a radiator until 1 bar is reached or ask for

assistance from an authorised company.

In the event of frequent pressure drops, contact

a qualied rm for assistance to remove any

system leakage.

2.9 SYSTEM DRAINING.

To drain the boiler, use the special draining

valve (Fig. 1-3).

Before draining, ensure that the lling cock is

closed.

2.10 ANTIFREEZE PROTECTION.

The “Victrix TT” series boiler features an

antifreeze function that lights the burner auto-

matically when the temperature falls below 4°C

(standard protection down to min. temperature

of -5°C). All information relative to the an-

ti-freeze protection is stated in Par. 1.3. In order

to guarantee the integrity of the appliance and

the domestic hot water heating system in zones

where the temperature falls below zero, we rec-

ommend the central heating system is protected

using anti-freeze liquid and installation of the

Immergas Anti-freeze Kit in the boiler. In the

case of prolonged inactivity (second case), we

also recommend that:

- disconnect the electric power supply;

- the central heating circuit and boiler domestic

hot water circuit must be drained. In systems

that are drained frequently, lling must be car-

ried out with suitably treated water to eliminate

hardness that can cause lime-scale.

2.11 CASE CLEANING.

Use damp cloths and neutral detergent to clean

the boiler casing. Never use abrasive or powder

detergents.

2.12 DECOMMISSIONING.

In the event of permanent shutdown of the

boiler, contact an authorised company for the

suitable procedures and also ensure the electri-

cal, water and fuel supply lines are shut o and

disconnected.

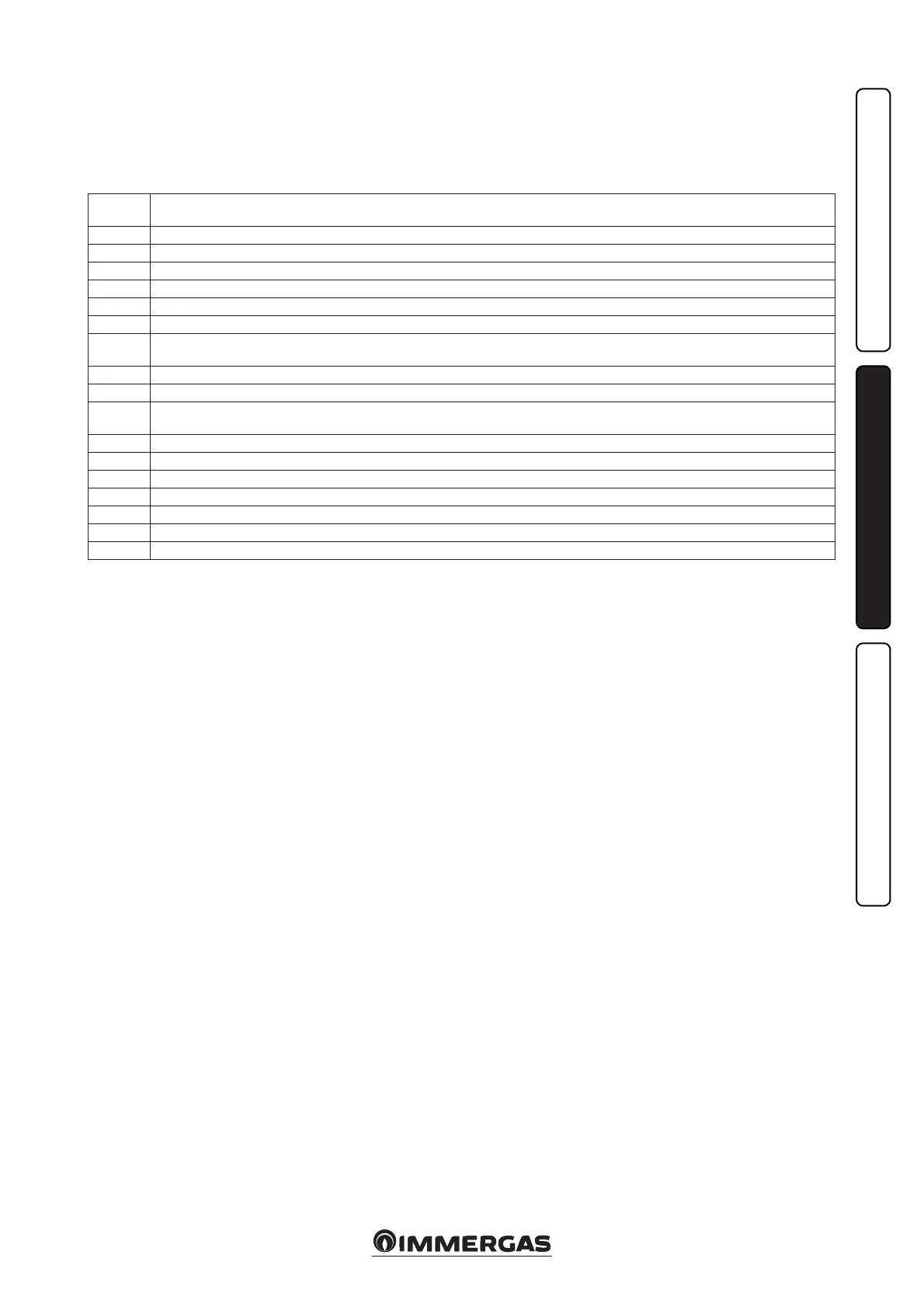

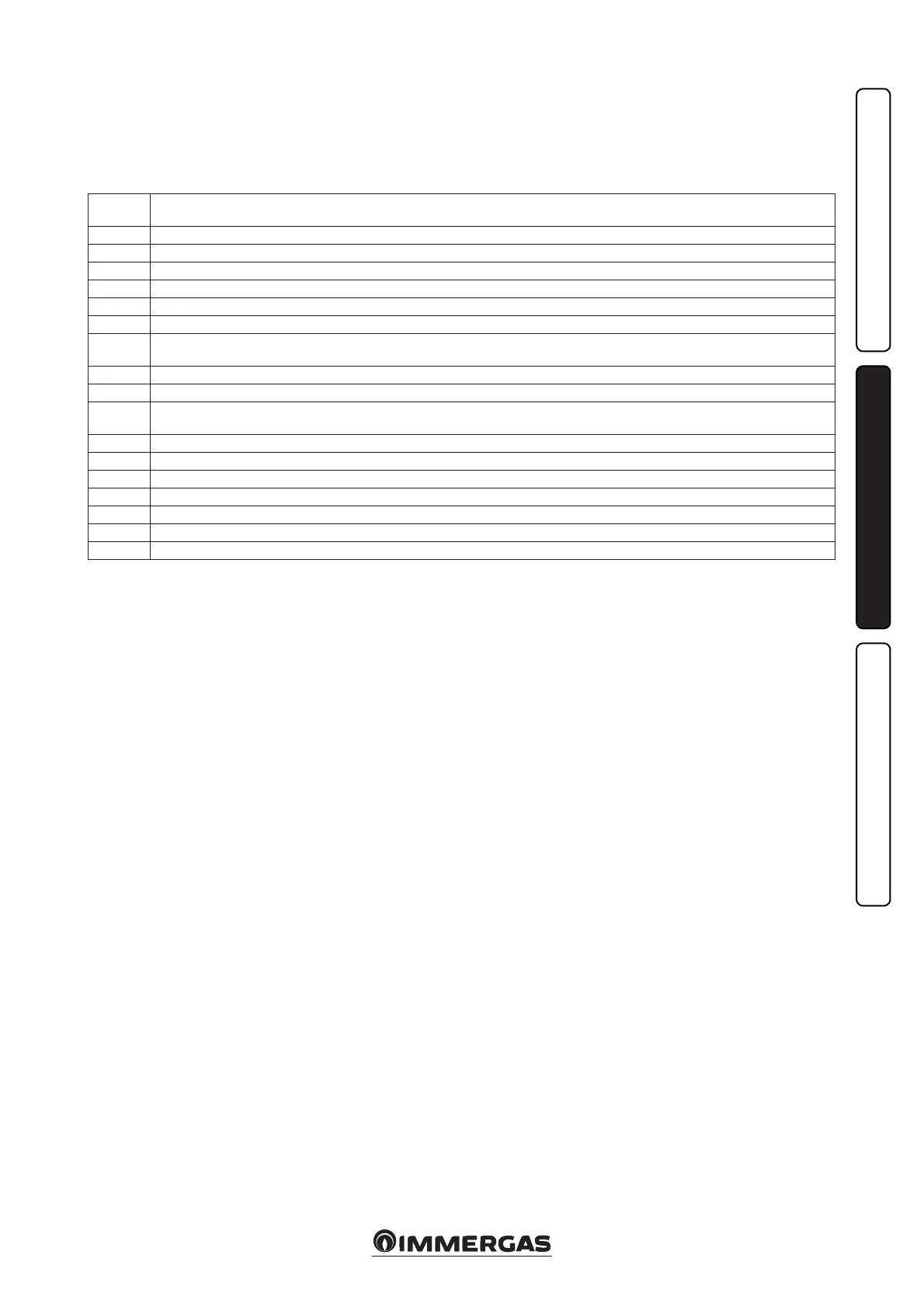

2.6 INFORMATION MENU.

By pressing the "Info" button (5), the “Infor-

mation menu” is activated for at least 1 second,

displaying some boiler operating parameters.

Id

Parameter

Description

d 0.0 Not used

d 0.1 Displays the combustion signal

d 0.2 Displays the primary exchanger output instant heating ow temperature

d 0.3 Displays the instant output temperature from the DHW exchanger

d 0.4 Displays the values set for central heating set

d 0.5 Displays the values set for DHW set

d 0.6

Displays the external environment temperature (if optional external probe present)

If the temperature is below zero, the value is displayed ashing.

d 0.7 Displays the temperature of the inlet DHW (with optional DHW inlet probe present)

d 0.8 Not used

d 09

Displays the list of the last ve anomalies.

(to scroll the list, turn the CH temperature selector (4))

d 1.0 Anomaly list reset. Once “d 1.0” is displayed, press the Reset button; deletion is conrmed via the “88” symbols ashing for two seconds.

d 1.1 Displays the temperature read on the safety ow probe

d 1.2 Displays the pump operating speed

d 1.3 Not used

d 1.4 Displays the pump ow rate (lh/100)

d 1.5 Displays the fan operating speed (rpm/100)

d 1.6 Displays the temperature read on the ue probe

Press the "Info" button (5) to scroll the various

parameters.

To exit the menu, press the “Info” button (5) up

to the end of the list, or by pressing the “Reset”

button (2) or by waiting for 15 minutes.

With the menu active, the indicator (14) will

alternately show the indication of the parameter

via the letter “d” plus the number of the param-

eter that is being displayed and the value of the

parameter itself.

Loading...

Loading...