14

STV75 ed 01/08 VICTRIX 75

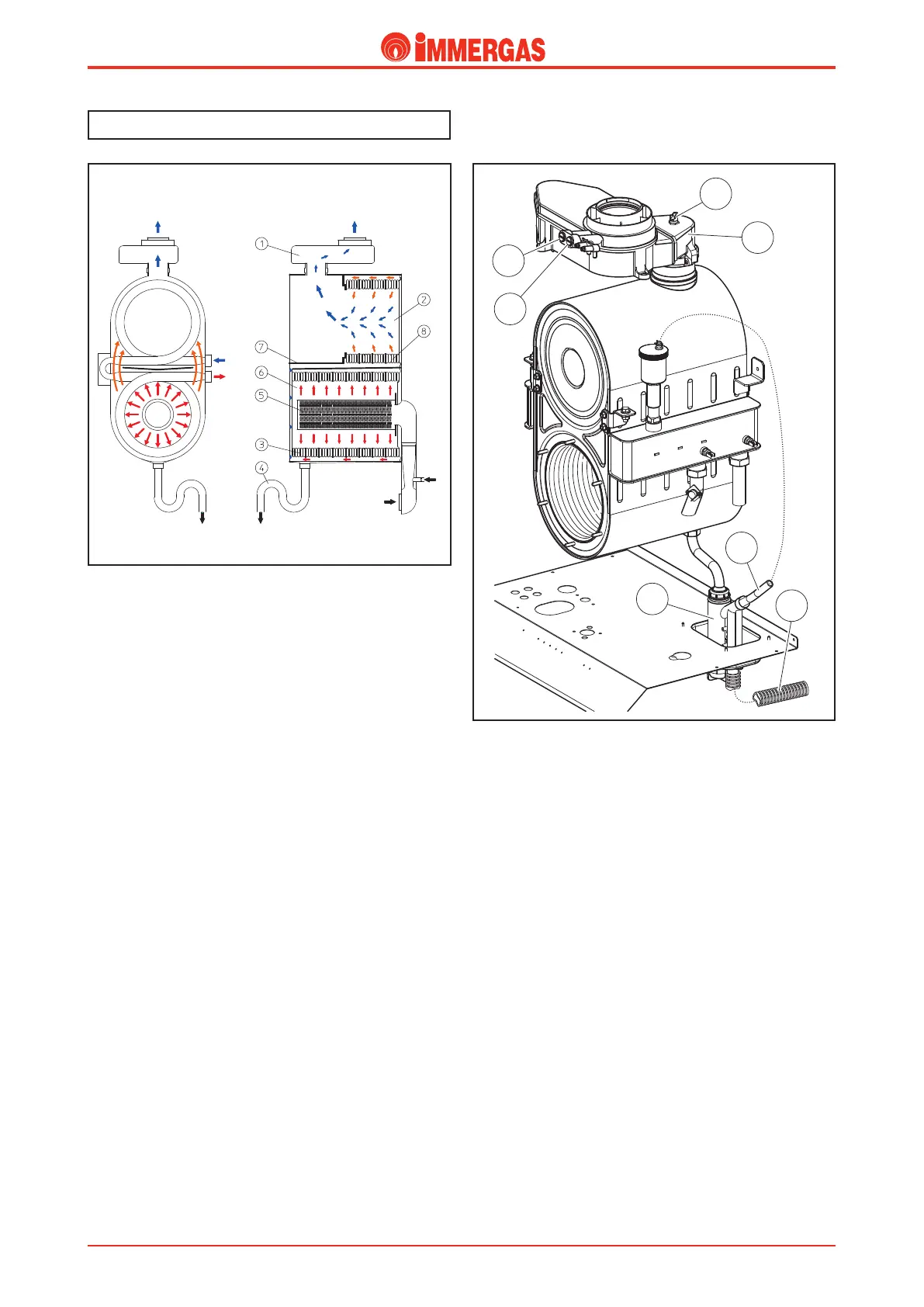

Condensate drain trap (4).

It takes the condensate from the bottom of the module since

this condensate collects when the boiler is working.

Its outlet is connected to the drain pipe (11) towards which it

allows the passage of water but not ue which could happen

if the evacuation pipes get clogged.

e trap’s water column is, in fact, higher than the pressure

inside the sealed chamber (module) with the fan working at top

speed and the evacuation pipes clogged to working limits, thus

avoiding the products of combustion from being discharged

through the condensate drain. When switched on for the rst

time the ue could be discharged through the drain pipe (11)

but this stops after only a few minutes once the condensate

has reached the appropriate height. If this does not happen

soon, ll the trap with water after rst having removed the

small pipe (10) which must be put back in place when you

have nished.

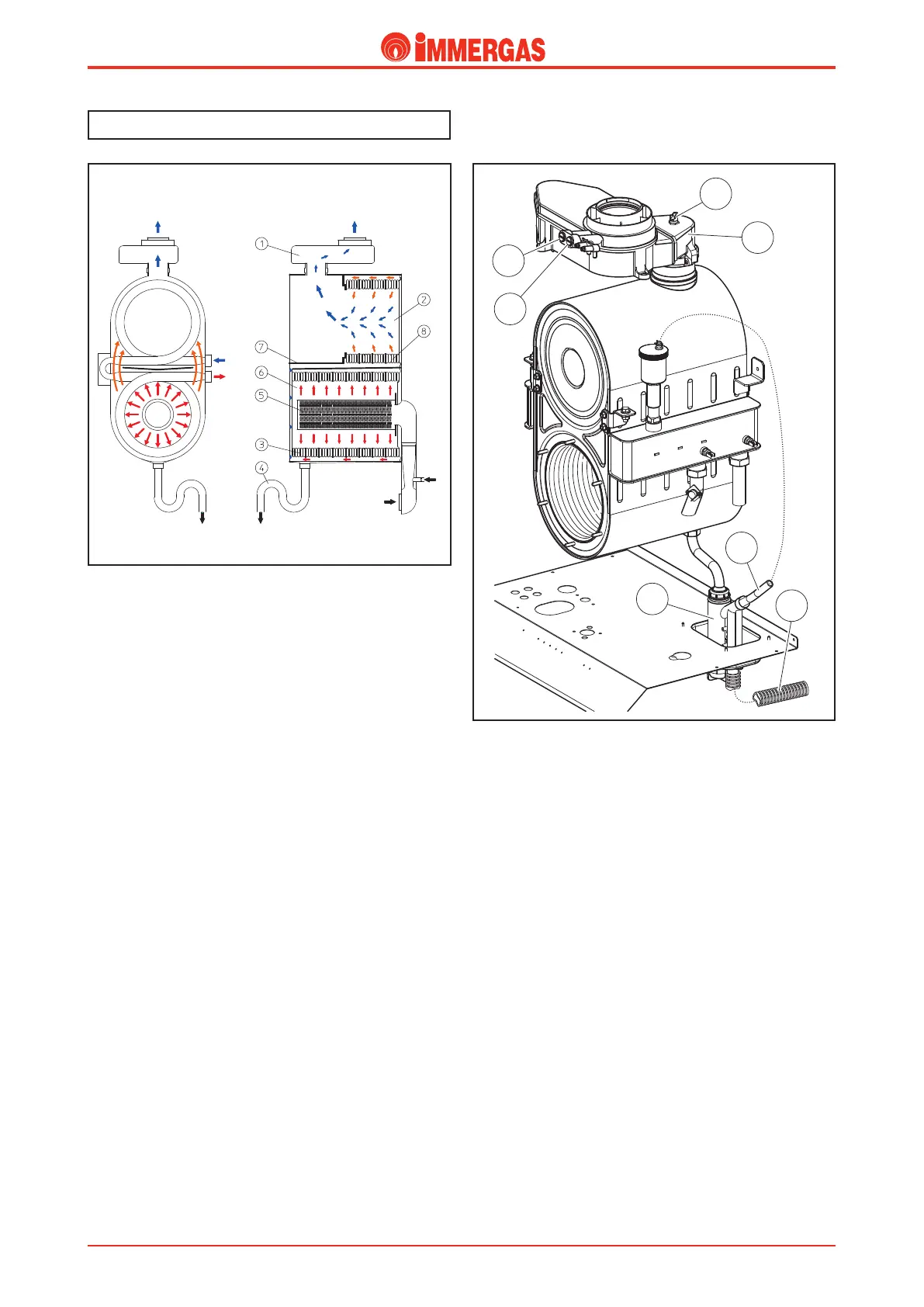

Air-ue intake traps (8-9).

e top of the appliance features two intake traps with screw

closing accessible from the front (after having removed the

plastic cover) and from where combustion air (8) and ue (9)

can be sampled.

Flue circuit.

Operation.

Operation of the fan positioned at the inlet of the air-gas mix

duct ensures the forced expulsion of the exhaust ue produced

by the cylindrical burner (5).

e ue directly hit the rst eight elements of the primary

exchanger tted in the sealed combustion chamber (6) on

the bottom of which is a steel plate (7) that separates it from

the condensation chamber (2) and deviates the ue outside

the module.

In this way, the exhaust gases, before entering the condensation

chamber (2), hit the last three (3) elements of exchanger inside

which the primary circuit return water ows.

is cools the products of combustion even more and fa-

cilitates condensation before exiting through the draught

diverter (1).

e condensation water that forms inside the exchanger, in

the draught diverter and possibly in the extraction ducts, ows

down to the bottom of the module from where, before being

runo, it is conveyed to a siphon (4).

Flue hood (1).

is is connected to the top of the condensation module and con-

veys the combustion products to the ue exhaust at the top of the

appliance.

It is involved in the transit of the ue and the condensation water

that has formed inside or in the exhaust pipes.

It is made of plastic resistant to the corrosive eects of condensate

and is suitable for working at a temperature of up to 130 °C (max

ue temperature with 85 °C ow = 78 °C).

e ue hood and ue exhaust duct are protected by a thermostat

(12) that is triggered when the temperature exceeds 90 °C.

Gas

Air

Condensate discharge

Flue exhaust

Flue exhaust

M

R

Technical DocumentationTechnical Documentation

Loading...

Loading...